Completed a special 2-roller fairlead for a cave-"digging" project I was involved in a for a couple of years or so.

"Digging" in this context means removing umpteen thousands of years' worth of naturally-accumulated sediments and rock falls ( small boulders in this case) choking the passage, to find what lays beyond.

The difficulty was that manually hauling buckets or rocks up a shaft ate pulleys for breakfast. After I'd made yet another simple sheave running on the shank of a "through-bolt" masonry-anchor, I realised the problem was firstly the relative positions of everything meant the rope is pulled at a low angle to the line of the bolt; and secondly, the crew would do nowt about it a sticking sheave until the muddy rope had lapped a bloomin' great groove in it and the bearing bush!

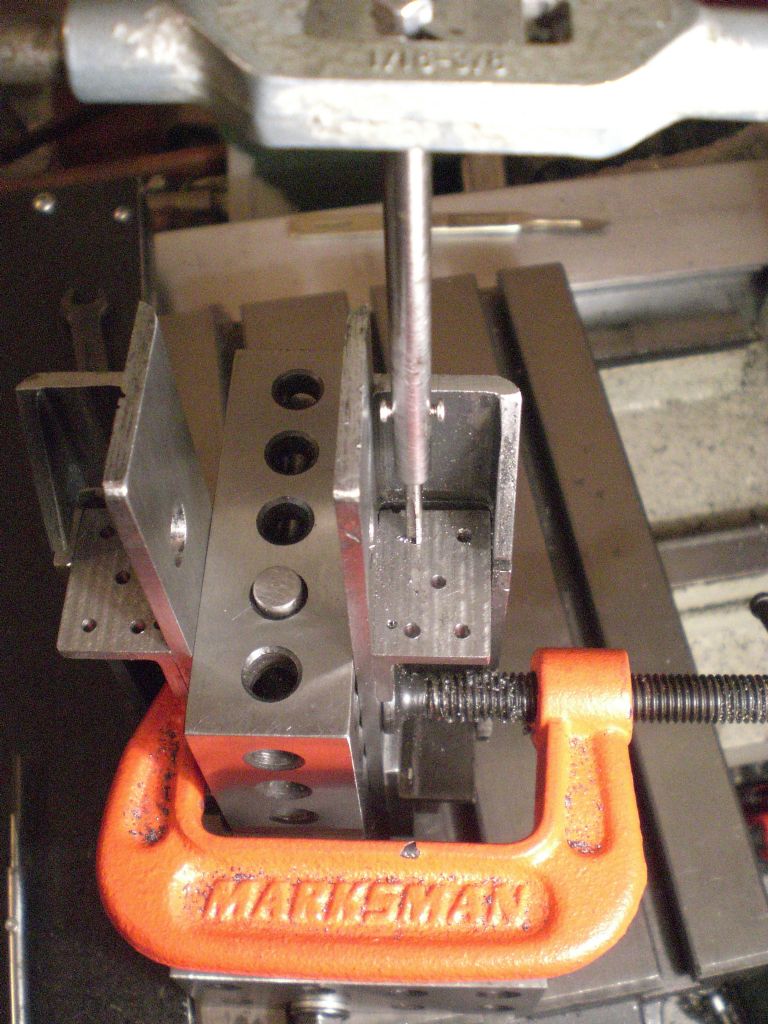

So, a 2-roller fairlead, which I will deliver tomorrow with advice on how I intend it being installed, and a bag of assorted spare washers, spacers and building shims so it can be screwed to the irregular rock wall by the original and a second, through-bolts.

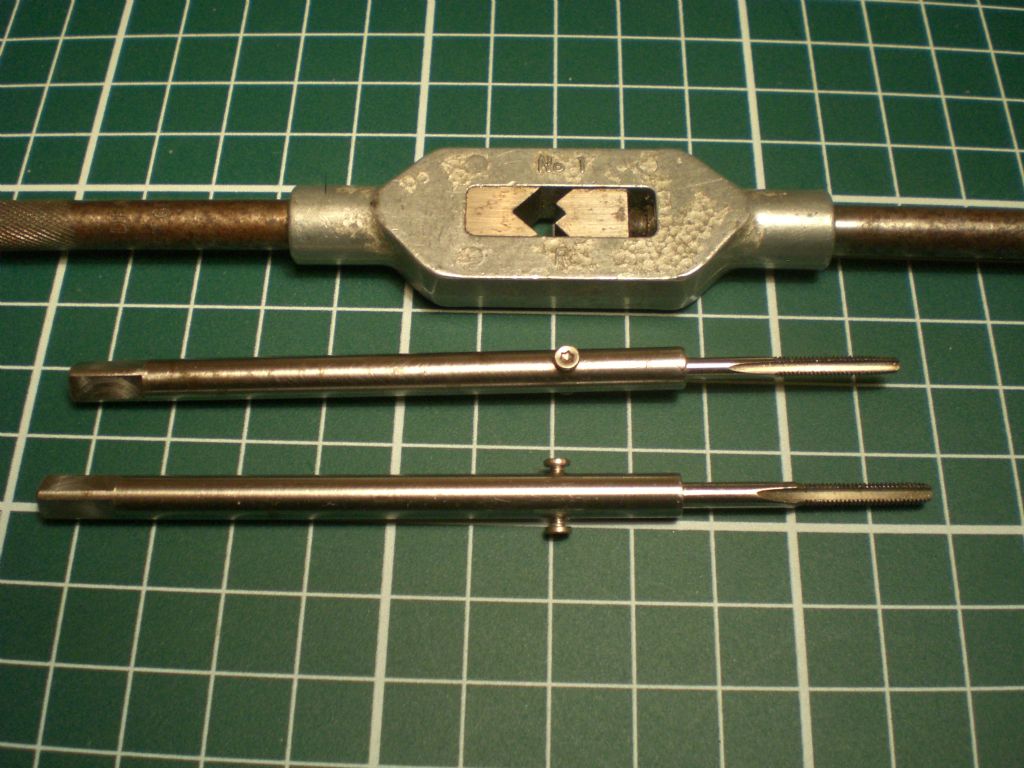

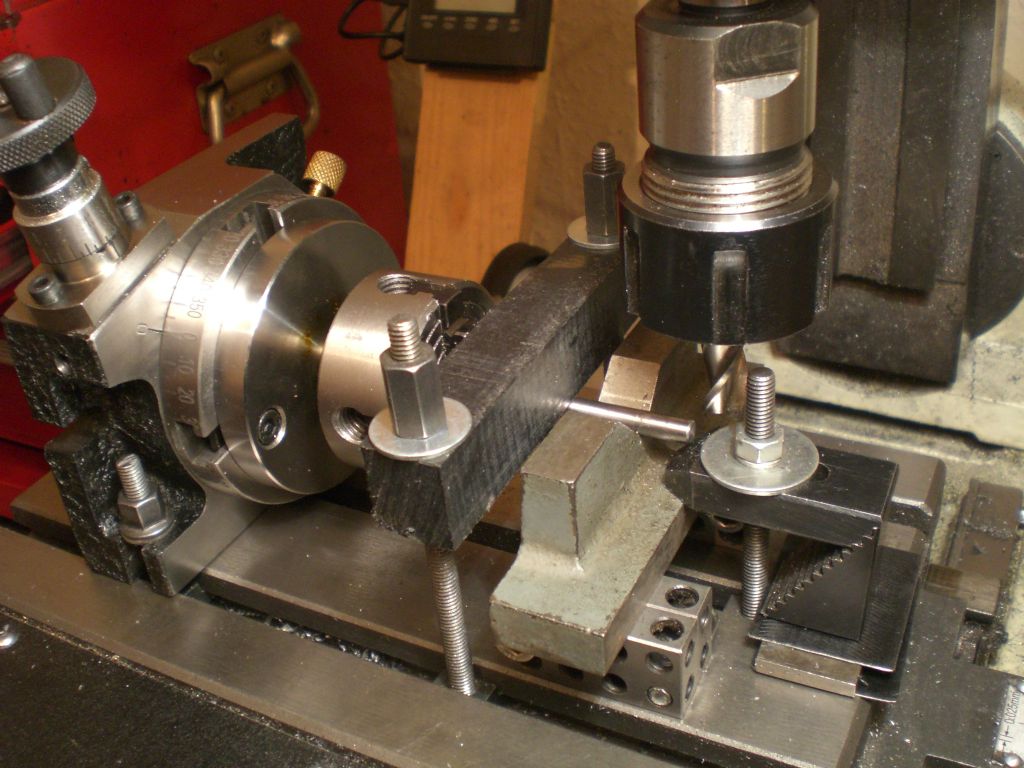

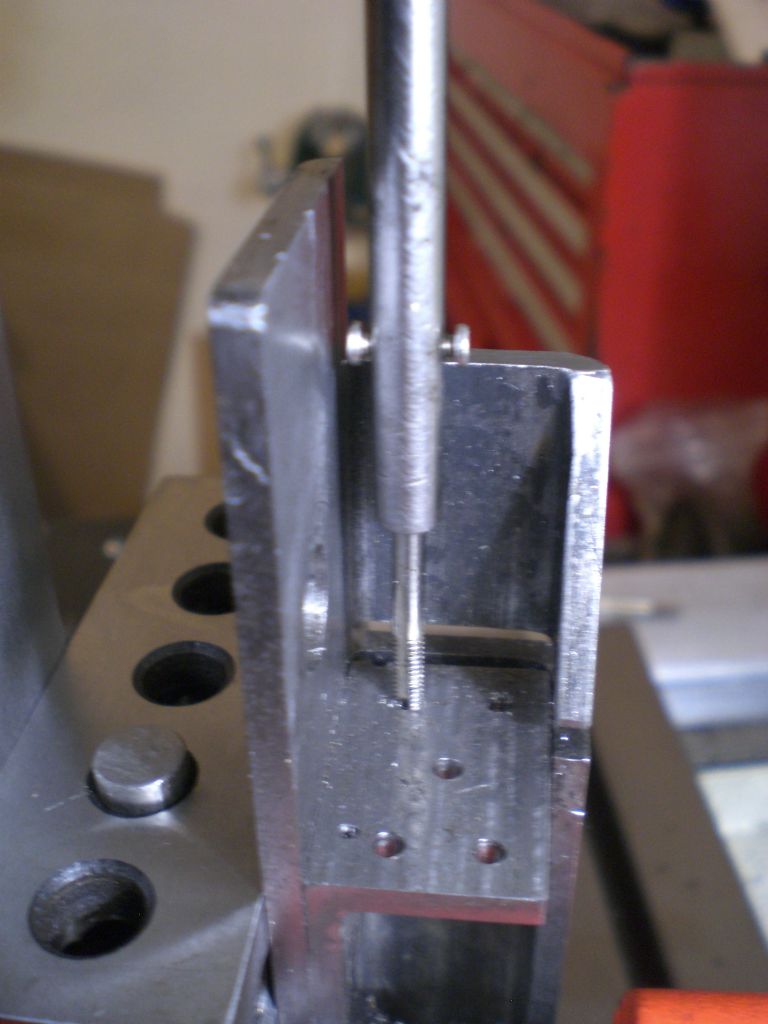

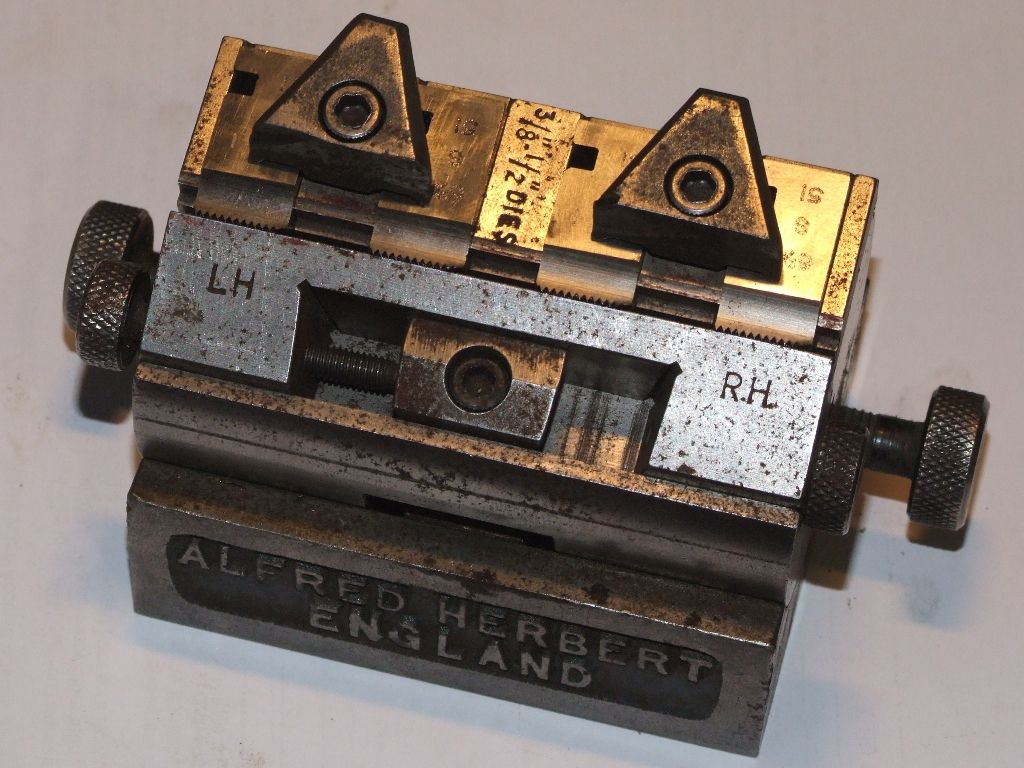

The rollers are of Nylon with a wearing surface cut from a piece of scaffold-tube. The horizontal one runs on the shank of an M10 bolt also helping hold the vertical roller's column to the assembly together, the vertical roller is on a spigot on that column, retained by a threaded thrust-washer and Nyloc nut: the rope has to be hooked over this twice per raising/lowering operation.

The frame is a confection of bits cut from structural-steel sections, and accuracy is not of the essence so don't look too closely.

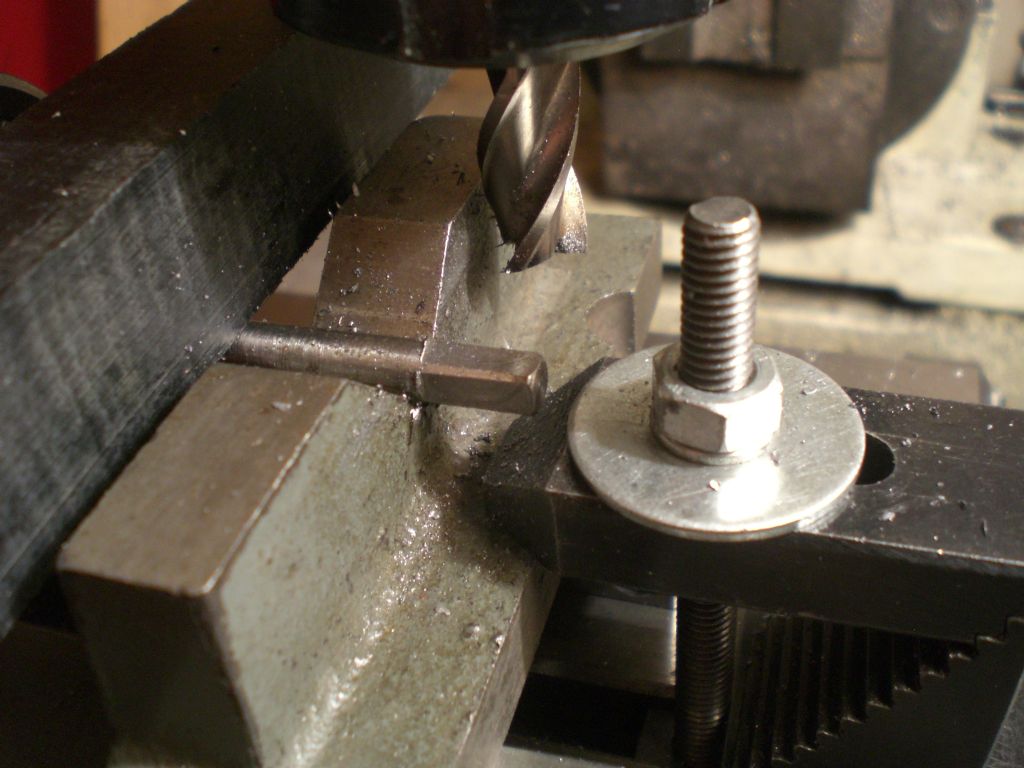

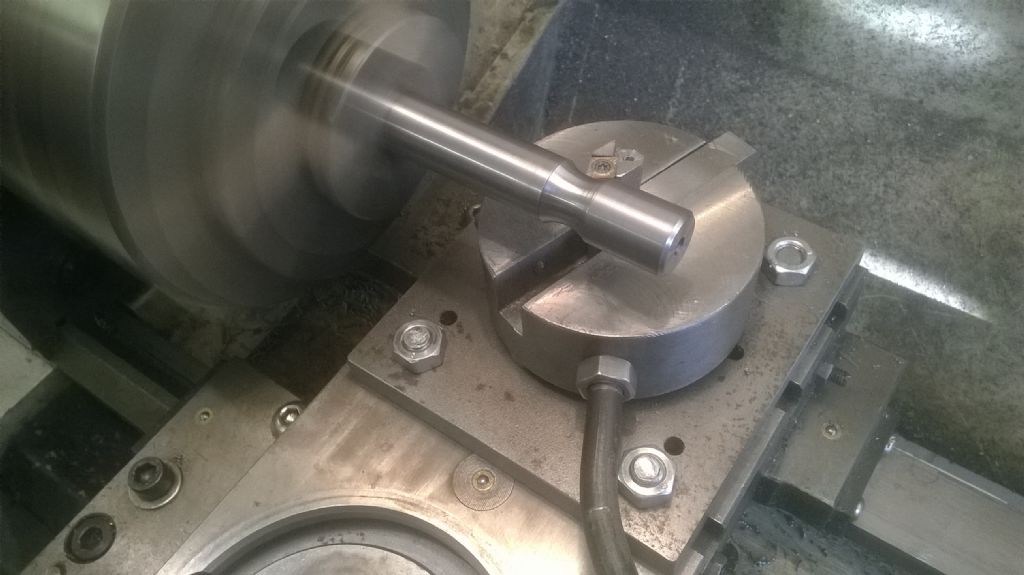

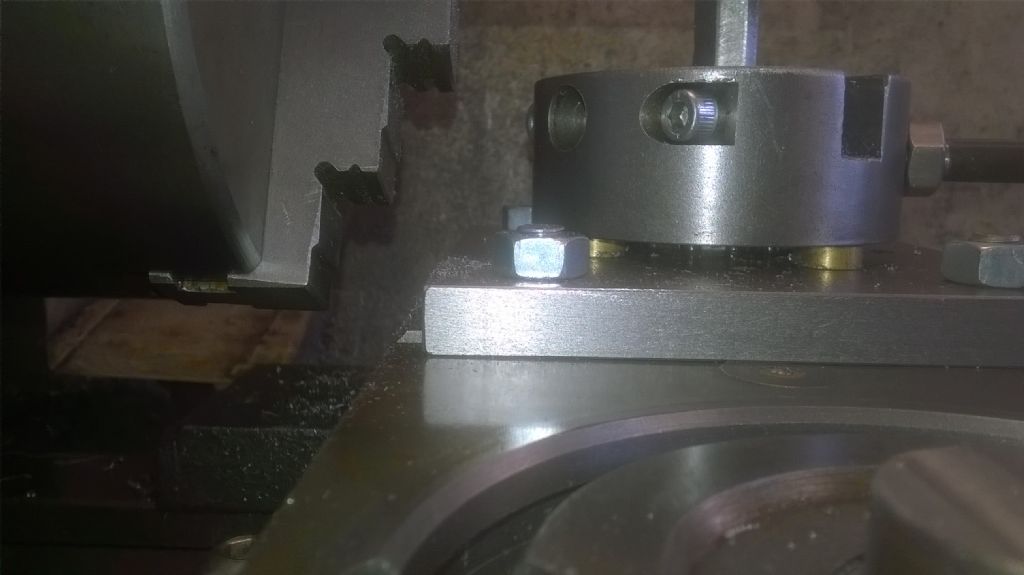

Making the stainless-steel thrust-washer was an experience. My generic Taiwanese band-saw spent literally hours cutting a slice from some 2.5" dia. bar. Luckily the unknown grade proved nice to machine, on the Myford 7, but parting-off was a matter of low speed and lots of lubricant for the insert-tool in the rear tool-post.

Still, modifying another stainless disc for a spacer for mounting the fairlead, I ran the lathe fast with an insert-type boring-bar, and a brush of lubricant, perfectly well.

(Incidentally, I have found it misleading that carbide inserts "have " to be worked at high speed. They can be: they are made for such duty industrially, but I find they give as good or indifference finishes as HSS, on the same material, at modest speeds. I suspect the operator, well, this one, first!)

++++

Tried to use the two rollers at right-angles as an exercise in trying after a long lay-off in despair, to tackle the problem of 3D modelling in TurboCAD. I had drawn them orthogonally, for future spares reference; but isometric CAD is a black art indeed. Luckily TurboCAD does not need it as a preliminary to the 2D workshop drawings, as Fusion and Alibre appear to need.

Failed, but did start to determine how the different classes of "solid" react to simple moves like changing their sizes. Sometimes trying to increase the height of a figure, moves it instead, so I endeavoured to find the (or any) pattern in such behaviour.

++++

For the geologists among you…

The cave, called Spider Hole, lies in the upper reaches of Cheddar Gorge, and has formed in the almost-vertical plane of a strike-slip fault in one of the anticlines forming the Mendip Hills. It contains so far known, two sizeable chambers resulting partly from fault-brecciation, partly from dissolution by percolation water. An area of the lower chamber has been marked with plastic tape to protect the pristine breccia floor and some unusual concretions, from being trampled.

A small inlet in the lower of chambers, on an end wall displaying the brecciated fault-plane, has deposited calcite. Another small inlet appears in the shaft where the fairlead will be installed. The water feeds the Gough's Cave River, not visible in the show-cave but emerging in the artificial lake opposite the cave entrance

The shattered rock has dropped down the fissure as dissolution creates voids to permit this; hence the digging being a slow process of manually moving possibly some hundreds of tons of shattered limestone and stacking it further up the cave, which is predominantly vertical. Where necessary the rocks are stabilised with mortar to give climbable sections but with minimum impact on the cave's natural appearance.

Some units of the Carboniferous Limestone are highly fossiliferous, with a lovely mass of coral at the foot of the shaft.

Steviegtr.

Steviegtr.