After drilling and tapping the required holes, I did a trial assembly of the 7 5/8" raising block I'm making for the milling machine.

Advantages:-

- It gives me enough headroom to do two of the jobs I've got lined up for the mill.

- It allows the full travel of the knee. (what's the point of a table that can be raised to the same height as the spindle nose?)

Disadvantages:-

- I'm going to need duckboards or steps to change tools and speeds, since the mill is already as much as I'm comfortable reaching up to without the raising block.

- I don't know yet what, if any, effect there will be on rigidity. That'll be found out when I start to use it.

- As shown in the first picture, The raising block could have been even taller. There's another 5" of quill travel available!

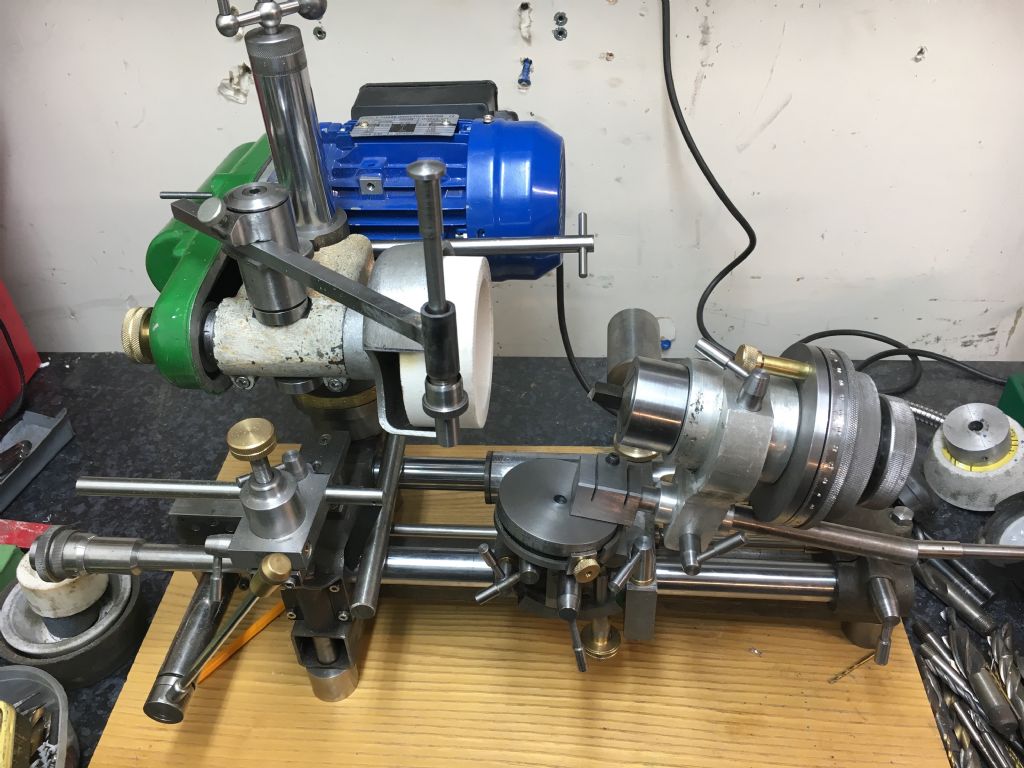

During the drilling of the holes, I hit a couple of hard spots that needed the drill to be resharpened. I stuck the drill in the Drill Doctor and ended up with variable (usually negative) relief several times. I've been having problems with the Drill Doctor 750X, even when following the instructions religiously, for some time. So the Drill Doctor has been struck off for gross incompetence and a Picador drill grinding jig was mounted on the surface grinder. Perfect results in a fraction of the time  . I had. previously, had reasonable results from the DD, but it gradually became unreliable even after replacing some of the wear parts at significant expense. Its now going to the local tip!

. I had. previously, had reasonable results from the DD, but it gradually became unreliable even after replacing some of the wear parts at significant expense. Its now going to the local tip!

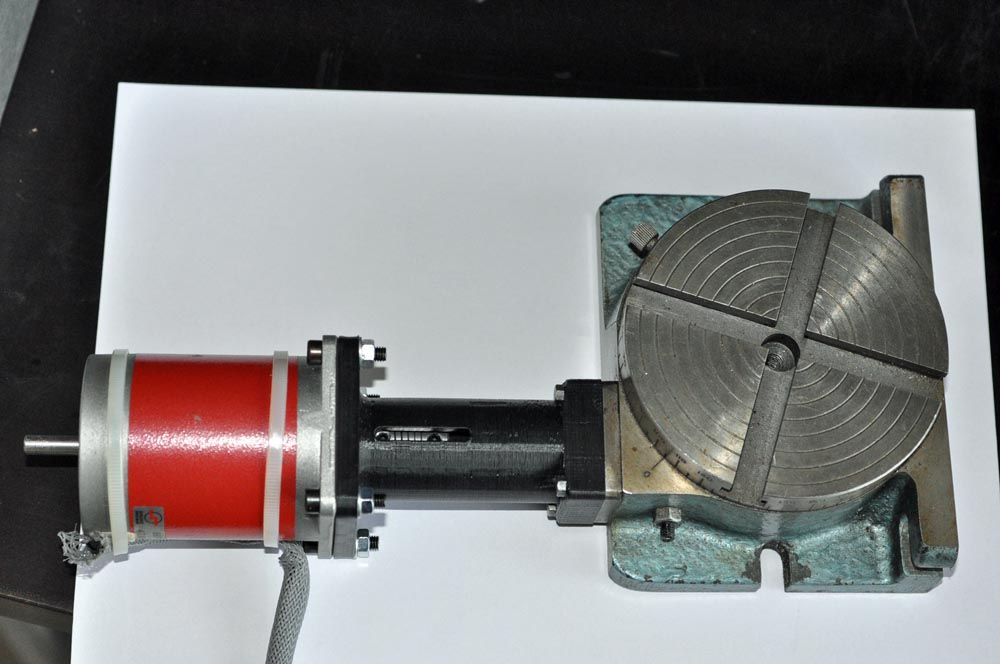

The lugs on the side of the raising blocks are to take some arms/brackets to hold the milling vices and the rotary table and its chuck out of the way, but where I don't have to lift them onto the table when I need to change them.

Edited By Mark Rand on 12/12/2018 00:01:59

Tim Taylor 2.