Some more info on the Stepper 'Rattle-Damper' as I fitted to my stepper on the rotary table a few post back –

I dug around some more and found a half-decent patent on the subject – quite informative and useful. For those interested:

**LINK**

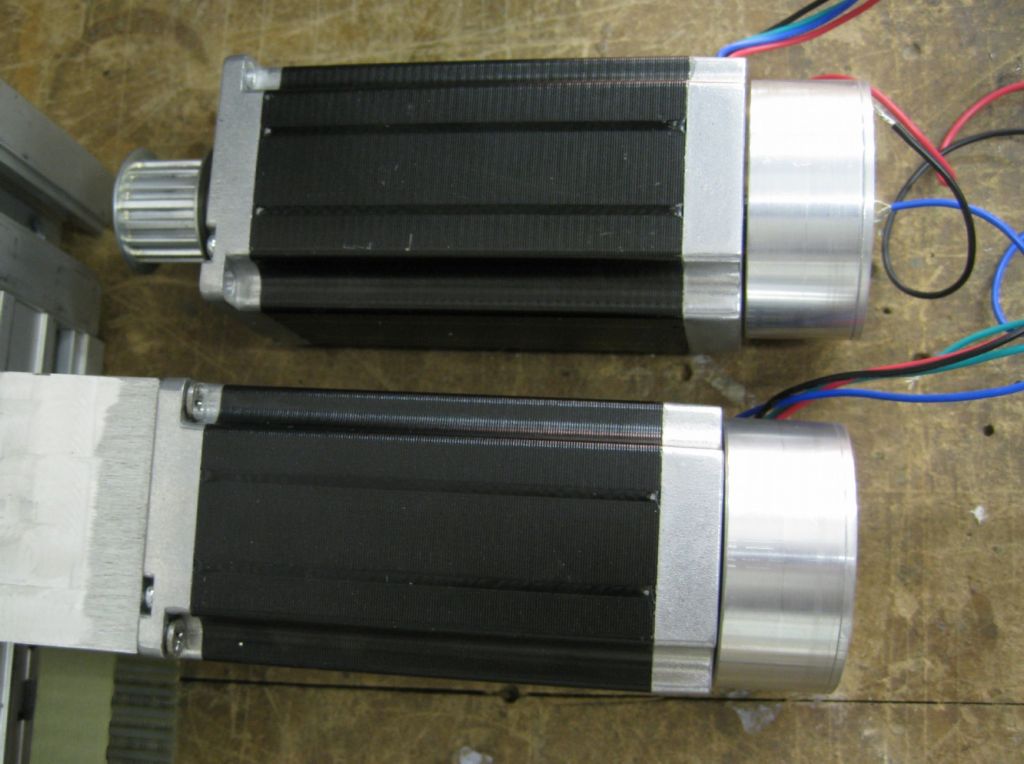

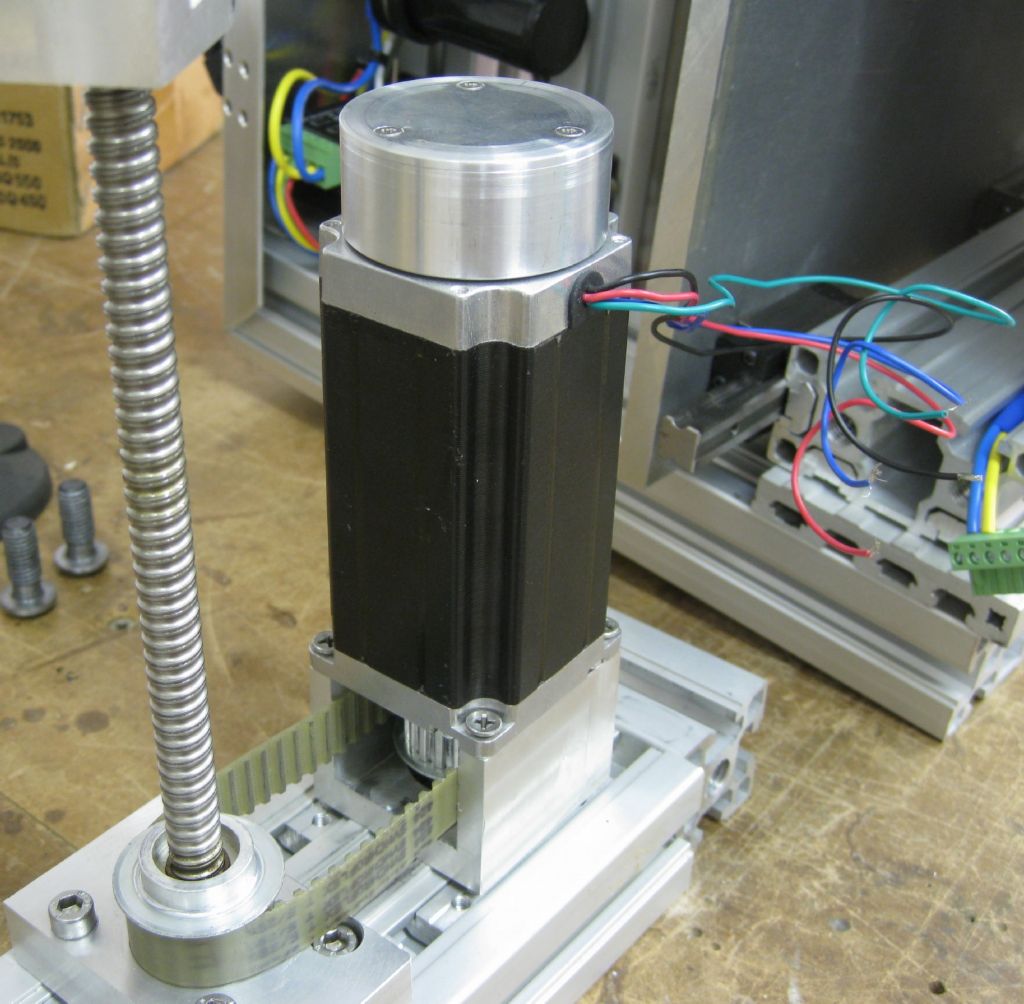

Going further, my PCB router/engraver uses NEMA-23 double stack motors ( same as the rotatary table) on each axis and I have always been disappointed by the rapids achievable. The motors drive balls screws via toothed belts and that seems to make it worse – the rotor resonances play havoc all over – stalls and steps lost. So I decided to make and fit some 'Rattle-Dampers' to each axis.

Engraving PCB's is quite hard on the machine – The tracks are many, and quite short most times. Feed speeds are typically 600 to 900mm/m- I cannot go faster as the spindle only does 22K-RPM and the track edges suffer with faster feeds. The machine really needs to be very rigid with high feeds as well, as any oscillation at motion start or end is a wobble in the track. I do tracks down to 0.2mm width, so a wobble is a cut track..

However, the big issue was that the rapids were not able to go much faster than 1000 to 1500mm/m and since the tools is spending more than half the time moving in rapid, that is a huge waste of time.

The three dampers – 55mm OD, 6 holes of 11mm, 6 slugs of 9.5mm diameter, 18mm long.

Fitted to one end of double shafted motors.

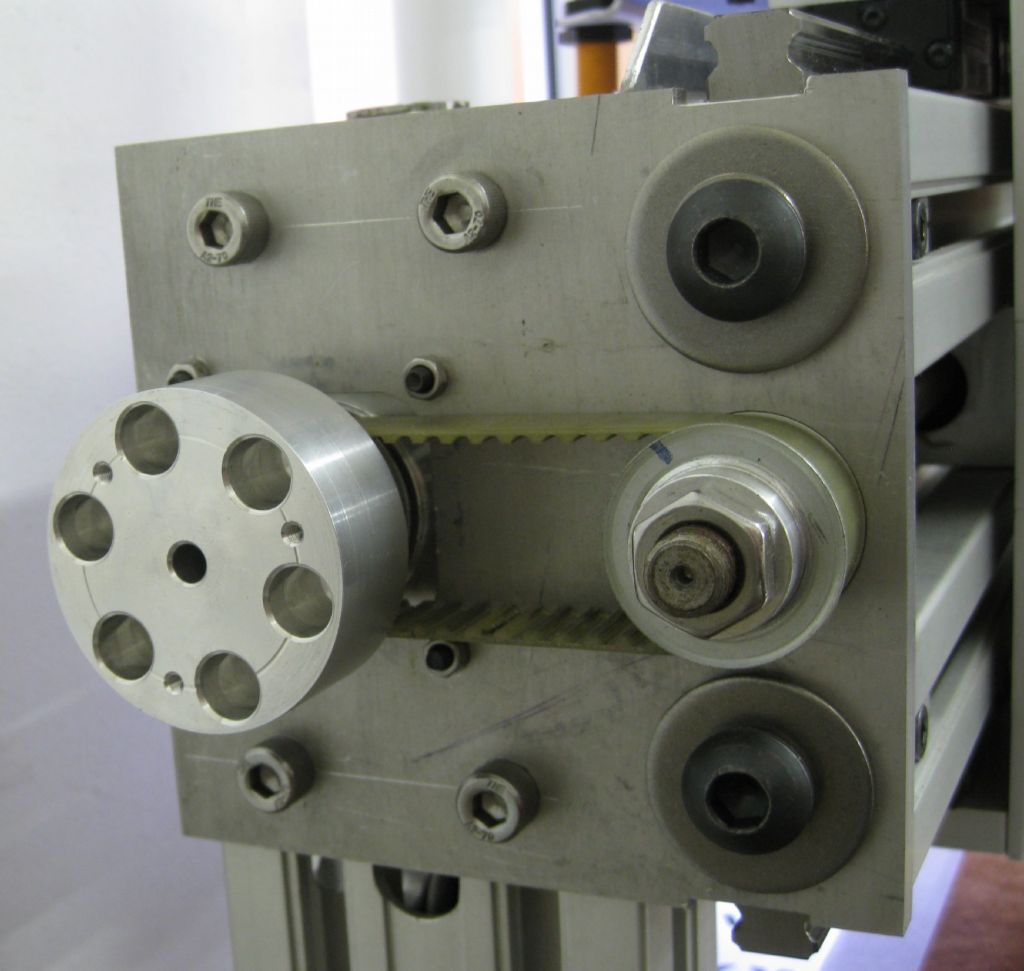

Fitted to the drive pulley of the X axis

The Y Axis

And the Z axis

The undamped machine gave –

X and Y Axis – max rapids 1400mm/m. Z Axis 900mm/m – Playing with accelaration on each axis did not change thing much.

The damped machine MAX achievable rapids increased to X,Y and Z – 9500mm/m – with NO lost steps after a 14minute PCB engraving – a 200mmx150mm really complex board with over 1400 tracks.

I reduced this to 5000mm/m on each axis and this gives a very comfortable machine. The steppers are driven from close to 60volts DC, with 1600uSteps/step

These Rattle Dampers are simply miraculous!

I did a video, but as usual, did not turn out well…Not to nauseating though.

Joe

NOTE: The captions in the video are WRONG!! Should be mm/MINUTE, not mm/SECOND !!!!!

Sorry…

edit – 'fir' to 'fit'…

Added note on incorrect caption units in video..

Edited By Joseph Noci 1 on 19/11/2018 09:45:47

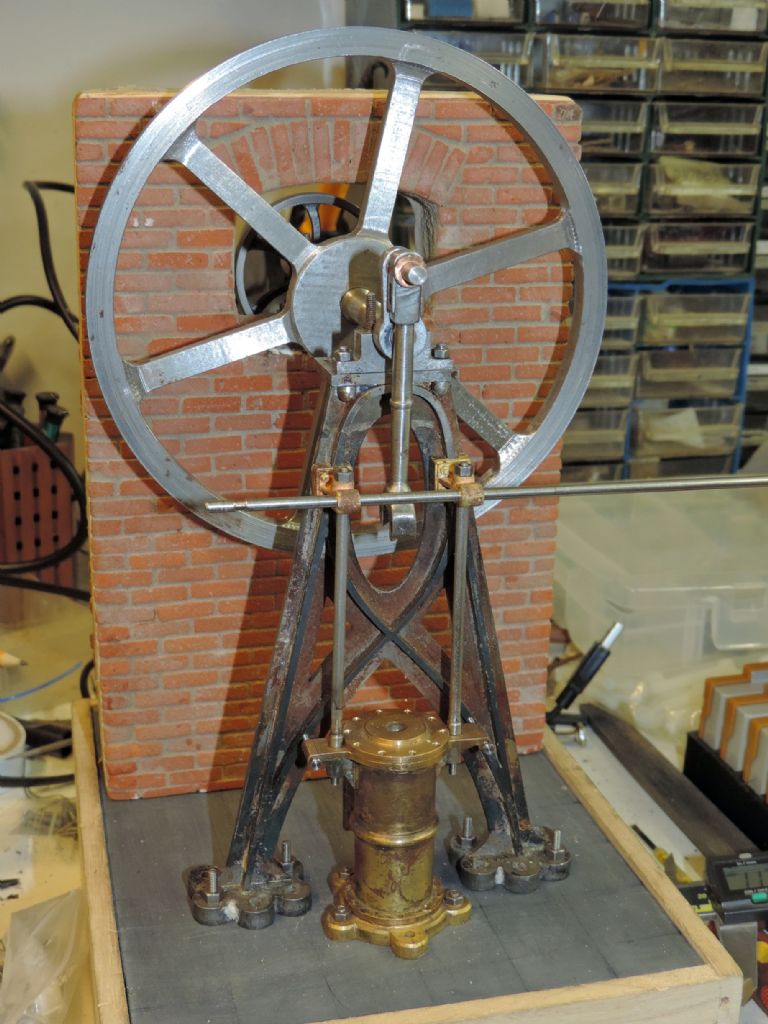

Tim Taylor 2.