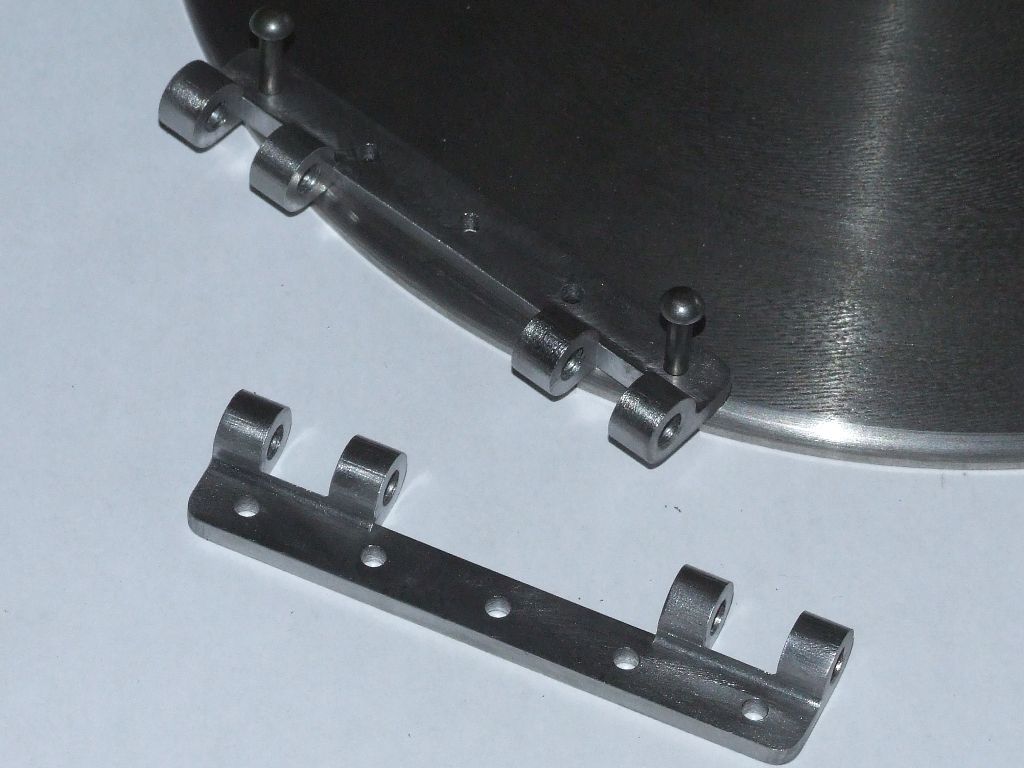

Well more this weekend, on and off. I've hogged the smokedoor hinges out of lumps of hot rolled steel:

Note the 1.5mm fillet on the hinge lugs, and between them, but not in the middle of the hinge. That matches fullsize, and will allow me to out count the rivet counters and accuse them of lack of attention to detail.

I've also got five rivet holes as per fullsize rather than the four shown on the drawing.

Generally the machining of the hinges is unremarkable, but just for the hell of it I created the rounded lugs using a form cutter on the horizontal mill:

These type of corner rounding cutters are a bit of a PITA to use. One starts with apparently quite a large cut; and nowt happens due to the concave form. Then, as you sneak up on dimension, it's only too easy to go a couple of thou past. It doesn't sound much, but it leaves a slightly recessed edge which is the devils own job to file away. Much better to stop a few thou short. Or use CNC!

The hinges have also been riveted in place:

The 3/16" rod which will form the hinge pivot fits nicely through the holes by hand. Feeling slightly smug about that, as I drilled the hole about an inch deep separately from each end. No point in drilling all the way through as the middle bit gets machined away.

I've also made, and riveted in place, the small brackets inside the smokebox ring that will hold the bar which the smokebox door locks to via the darts.

Having started machining the hinges with an old cutter I decided to retire it due to a crap finish. I wheeled out my new 10mm YG K-2 endmill from Cutwel. What a difference! I had to go and measure the finishes. The old cutter gave a finish of 5.7µm Ra (badgers), whereas the new cutter gave 1.05µm Ra (babies). The new cutter finish was mirrorlike. Oh, and I sort of fixed the icky LCD display on my surface roughness gauge. A folded piece of paper in a strategic place on the flexi PCB to the LCD got most of the bars back on the LS digit.

Andrew

Tim Taylor 2.