Posted by Andrew Hutchinson on 29/04/2017 01:03:25:

Joseph,

What brand/level of precision did you go for in the headstock bearings? Also how often are you changing out the HS oil? The refurb looks great.

Cheers,

Andrew Hutchinson

Hi Andrew.

I was very fortunate with the bearings – In South Africa there is an EMCO Agent/Rep that I have known for 35 years or so – He managed to find me a bearing set at EMCO Austria – seemingly the last set! I had asked him to get me 2, even 3 sets, as Hens Teeth are commonplace compared..but no luck, the last set..

Anyway, they were 'genuine' EMCO, made and marked by FAG Bearings.

However, the V10 bearing issue is a strange and complicated one. I have all the 'old' FAG bearing handbooks, encompassing the V10 era, and the P6 Spec ( which my bearings are) is a very vague and confusing one in the docs. Runout specs etc differ very, very little between the P6 and non-P6 standards in their docs, and the main difference seems to be in the outer race width and thickness, and therefore the total bearing assembled width, which might play havoc with the headstock assembly! And, it seems ( non verified – no one will tell…) that EMCO tasked FAG to select the bearings that met or surpassed their required specs, and then marked them P6 themselves – the P6 marking is not the same style/'colour' as the bearing part number.

Since I am stripping the lathe down, I thought that if I can get a new set, I would swap out, but those bearings are now unobtainable. No Manufacturer I contacted does a P6 in that size Taper Roller at all. Worse, from what it appears, the available bearings all seem to be of the 'narrower' race type, and I have not investigated the implications of that.

I changed oil around 20 worked hours after the last fit of the new bearings – I also fitted new gear change guide blocks when I did the bearing , so gave 20 work hours for all to bed down, and then drained, flushed and filled new. On stripping now ( actually 4 years and 5 months later) I up-ended the headstock into a flat container for a few days to drain the oil so I could see any debris – nothing at all, just a hint of very fine bronzy colour – from the guide blocks, but you have to look very closely..

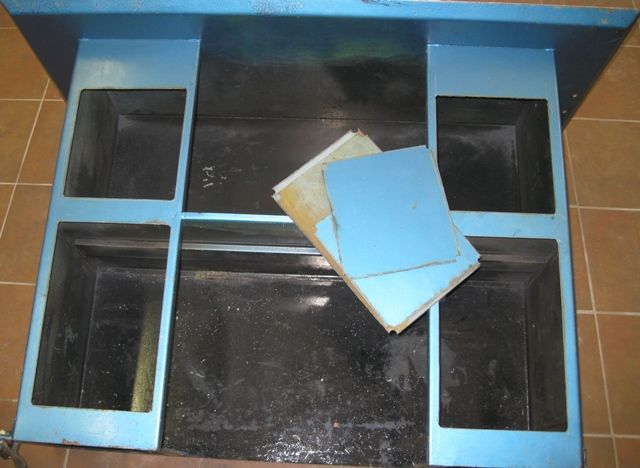

Today I make the cabinet drawers, do a final clean and sand of everything, and wrap it all up in bubble wrap with desiccant so it does not rust ( or not to much anyway) while I take forever stripping the lathe's paint..

Joe

Another JohnS.