Another non-flying weekend has passed.  Saturday was windy, and a bit wet. Looking at the webcam I don't think the gliding club flew, so I didn't bother going out. Serves me right for swapping days in the Nimbus. No doubt next Saturday, which I swapped from, will be a stonker.

Saturday was windy, and a bit wet. Looking at the webcam I don't think the gliding club flew, so I didn't bother going out. Serves me right for swapping days in the Nimbus. No doubt next Saturday, which I swapped from, will be a stonker.

On the plus side it meant I could spend time in the workshop. I finished off profiling and milling the valve rod couplers during the day. In the evening I updated my traction engine build diaries on other forums.

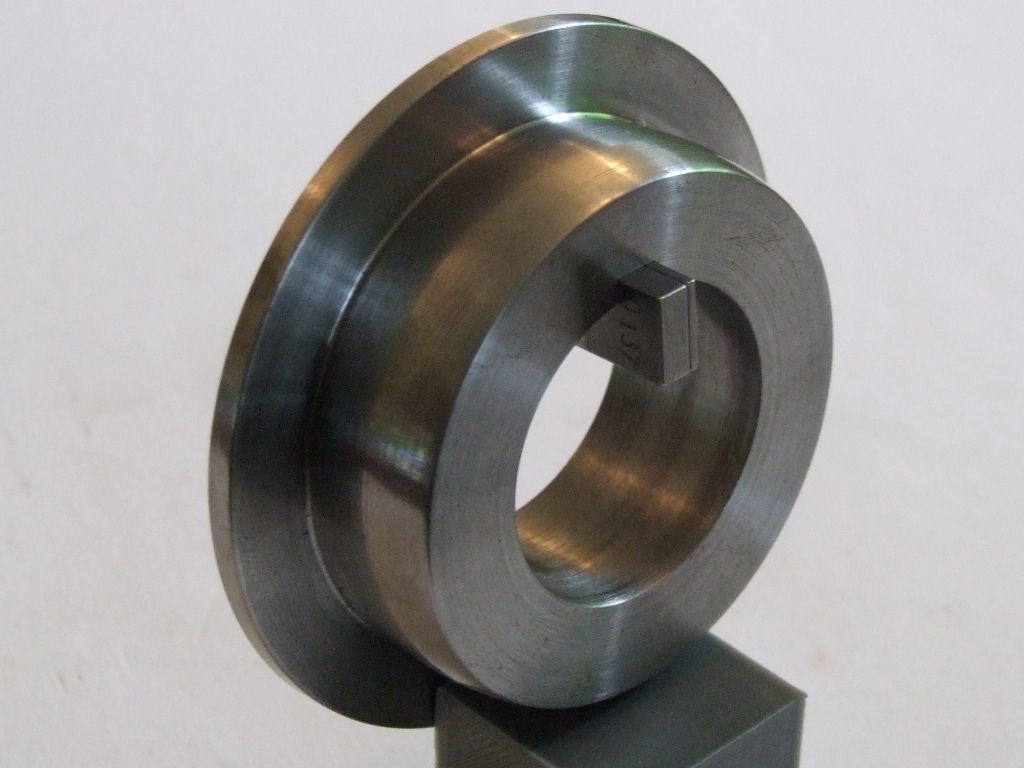

On Sunday I was up early as I was morning tug pilot. It was still quite windy, with low cloud. The club got a couple of two seaters out, and the winch. No call for aerotows, as you could reach cloud base on the winch. So I DI'd a tug, just in case, and did the daily and weekly fuel checks. The afternoon tug pilot turned up mid-morning so I decided to cut my losses and hand over early. Back in the workshop I finished off drilling some holes in a load of plastic boxes for a client. They're not urgent as the project manager is on hols this week, but it's good to get it done and dusted. Then I picked a couple of bowls of blackberries for the freezer, plus dessert. In the evening I swivelled the ram on the vertical mill and cut 3/16" keyways in the traction engine governor pulleys. The keyway tool was hand ground from 1/4" square HSS. It's one of the great ME myths that hand grinding is a black art only mastered by the cognoscenti, with the aid of complicated jigs.  Here is a pulley with gauge blocks hanging snuggly in the keyway:

Here is a pulley with gauge blocks hanging snuggly in the keyway:

The blocks add up to 0.187"; a 0.188" stack doesn't fit. That leaves enough to tickle out with a file when fitting the key.

After cutting the keyways, I dismantled the adjustable angle plate and lifted it on to the mill table, and then re-assembled. It's too heavy to lift when assembled. Sometime this week I'll get it set up and cut the tapered keyways in the traction engine flywheels.

Andrew

JasonB.

JasonB.