Turret , what a beautiful single part.

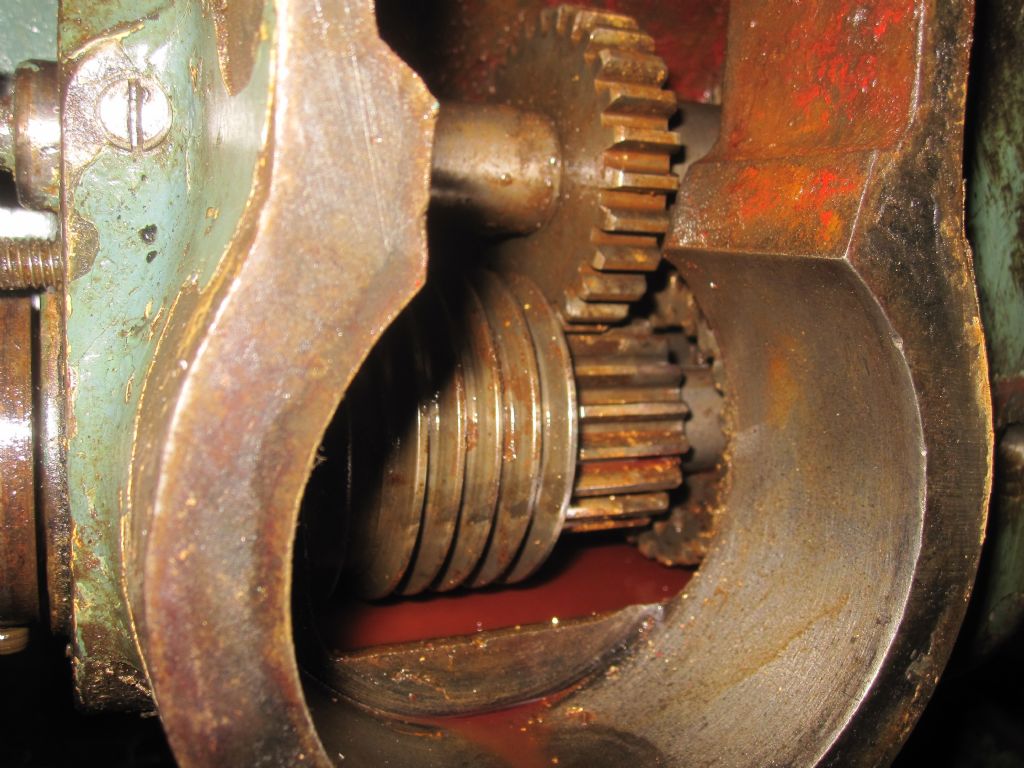

The corrosion on the horizontal power feed shaft to the turret. This is what the turret gearbox was seized to for 25 years and took weeks of kroil and hammering to free. But we did it !!!

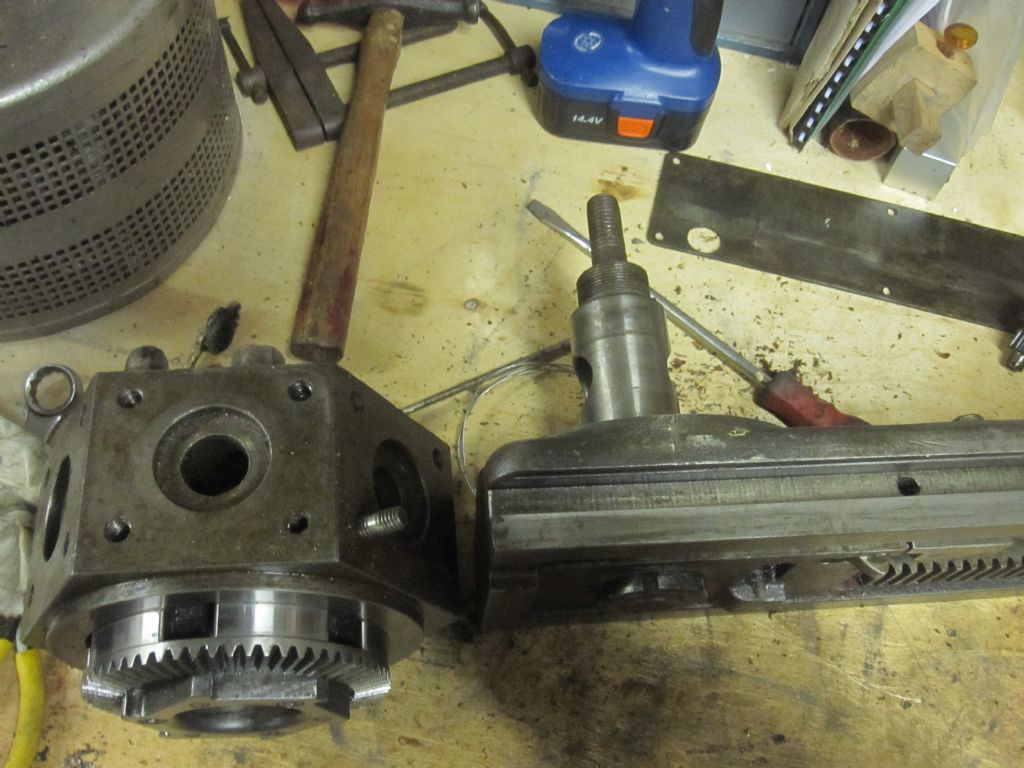

re assembling the vertical shaft, we (I) had split the lower gear case and had it welded back but it was swolllen and didnt fit so lots of sanding to get it back in, only on re-fitting did we realize it actually hindges on the lower round casing and pivots to engage on the upper gear.

finding the binding points on the housing after the welding fix.

the outer casing has an arm with a cam to push the vertical shaft onto the upper turret feed gear fixed to the manual feed.

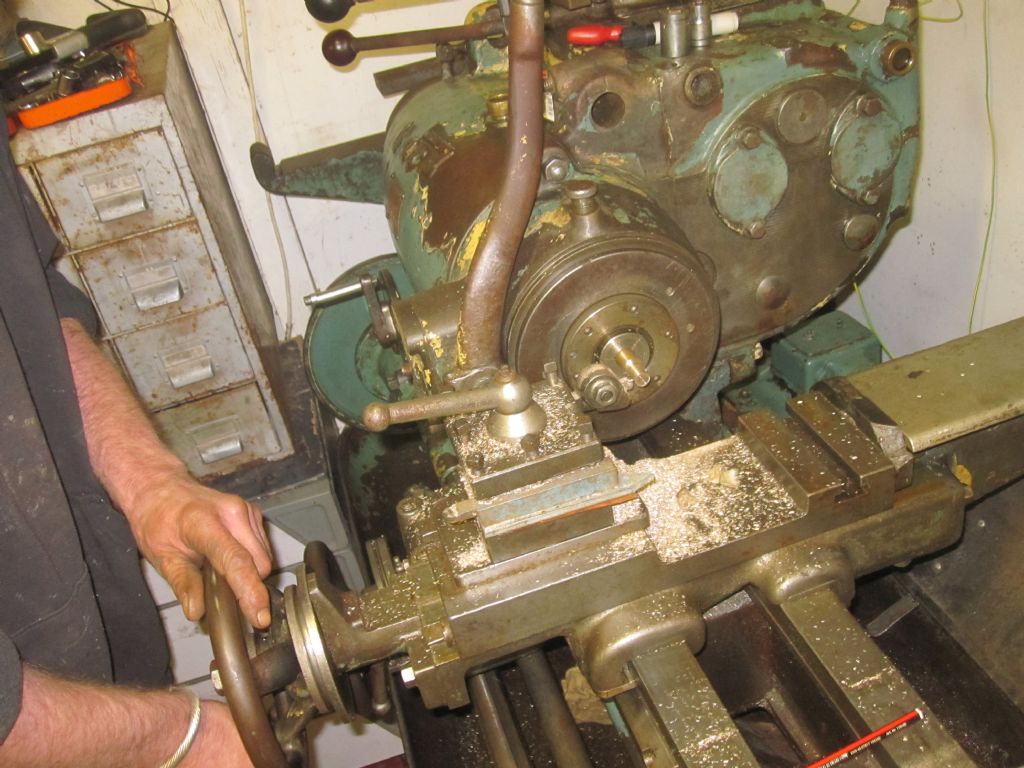

still making bits, although under load the spindle slowed considerably so still serious motor/gearbox problems.

Edited By Bob McDougall on 03/02/2018 00:22:42

James Tarff.