Posted by John Rudd on 31/01/2017 22:30:41:

Malc,

Does the Teco inverter have the ability to set a different frequency that is switchable using a digital input…,?

I have Teco inverter on my lathe ( a smaller version of yours, .75 hp) but havent really read the manual…..

If inverters had the flexibilty to set the frequency switchable from 0-50 and 0- to x hz it would make belt changing un-necessary if it could be changed by a switch…..

Something for me to look into……

Hi John,

Reading your question in conjunction with Clive response as well.

I have two Teco inverters that i have installed. Both models have a variable frequency potentiometer on the face of the inverter, like on the more expensive Inverteks.

I have a 2.2kw Teco EV series on my Harrison M300. Its a late machine (2003) which has more contactors and overload protectors than the earlier models. MEW 145 covered a conversion for mine. The logic control to the inverter in this article seemed overly complex so i did my own circuit diagram, got my electrical wizard friend check it, went ahead and rewired it all to utilise all the machine controls and interlocks, not really wanting to do any with the inverter, which i left set at 50Hz max. I can still use the pot on the front to vary speed if needed, but the M300 has such a good speed range i think it will never be necessary.

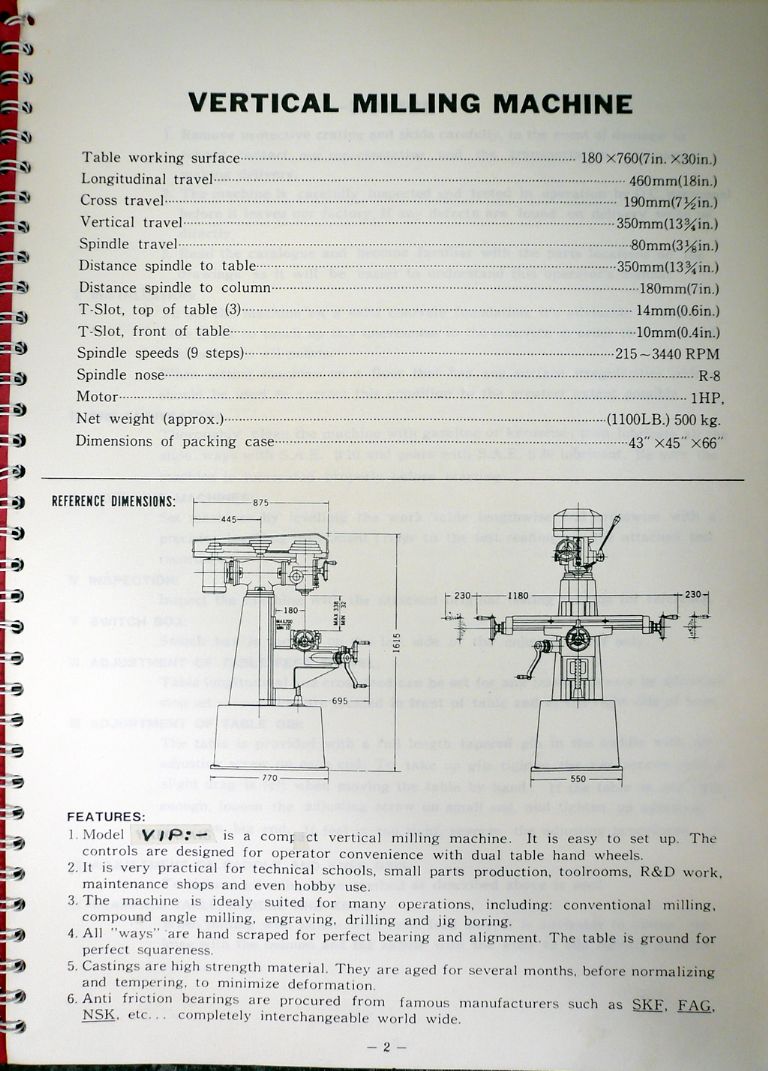

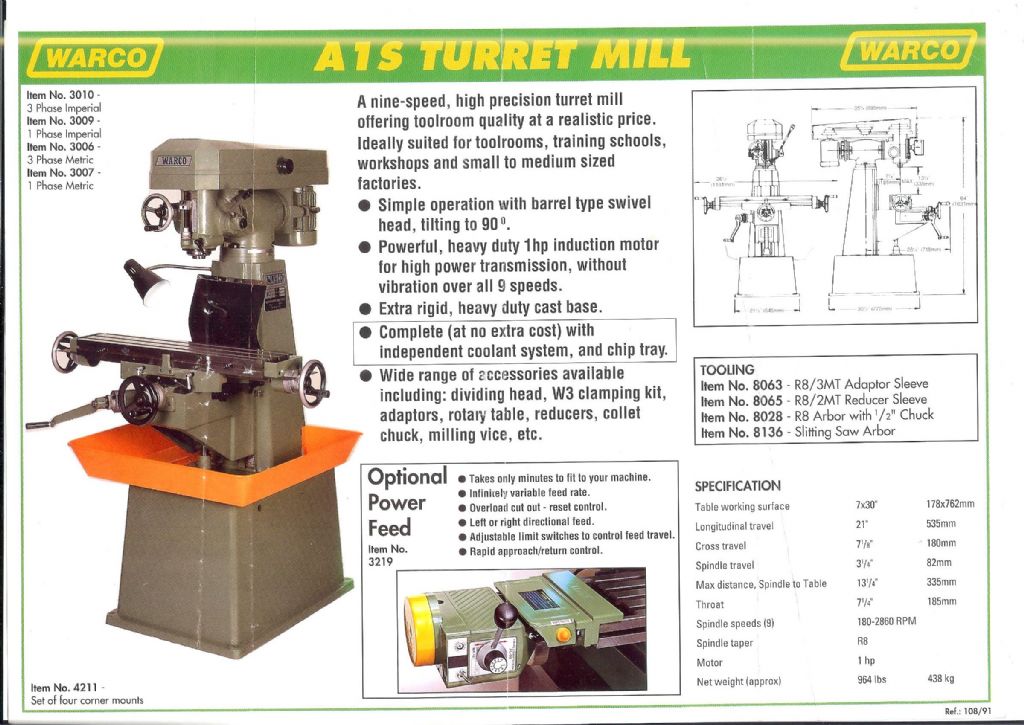

The Teco I have just installed on the VMC. is the L510 series 1.5kw model, which is to be used opposite to above in that i am using frequency range to change speeds.

I do not understand what you would gain by having switched frequency ranges. If you programme the inverter to use the potentiometer with a speed range from say 0 to 100Hz why would there be a benefit switching in between? I cannot see in the manual that you can use different ranges, only a min and max, but does not mean i have not missed it.

Its as Clive has established, setting a wide frequency range and then setting the belt position to achieve the optimum compromise of max speed, lowest speed, satisfactory motor cooling at lower frequency and minimum amount of belt changes if needed.

If its an issue of knowing exactly what speed you are doing and your inverter does not have the ability to display revs then its still really simple.

Once you are satisfied with the fixed initial belt position, buy yourself a digital tachometer like I just have.

You can get a decent one for not a lot of money. Use the tacho and at each of the potentiometers markings, take a reading and the do yourself a chart of frequncy setting vs RPM, which is what I would have done had I not got the parameters to do this on the Teco.

To generalise a little.

One of the big learning curves for me is using inverters and I have a lot to learn yet. When I first started looking at and learning about them, I download quite a few manuals ( and i mean quite a few ). I found some very easy to tead and follow right thru' to those that were megga difficult to understand. Loads of Youtube videos watched, each time gleebing a little more understanding.

I actually found the Invertek and Teco not to difficult to follow and these were makes high on consideration list.

Edited By MalcB on 01/02/2017 09:20:07

Stuart Bridger.