Hello all,

I keep saying i will use this forum more however due to work commitments i don't have that much time to get in my workshop and do interesting projects. That said i am currently in the process of machining my own Pre Charge air rifle from scratch so keep your eyes peeled if your into that sort of thing as i will post a build thread soon.

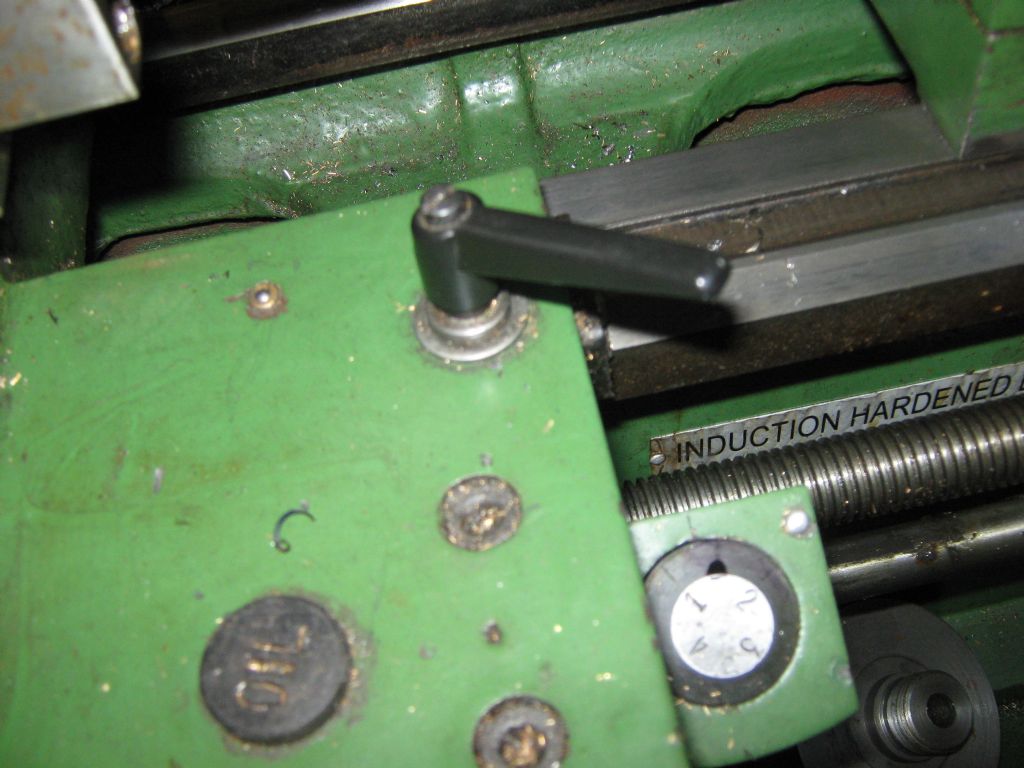

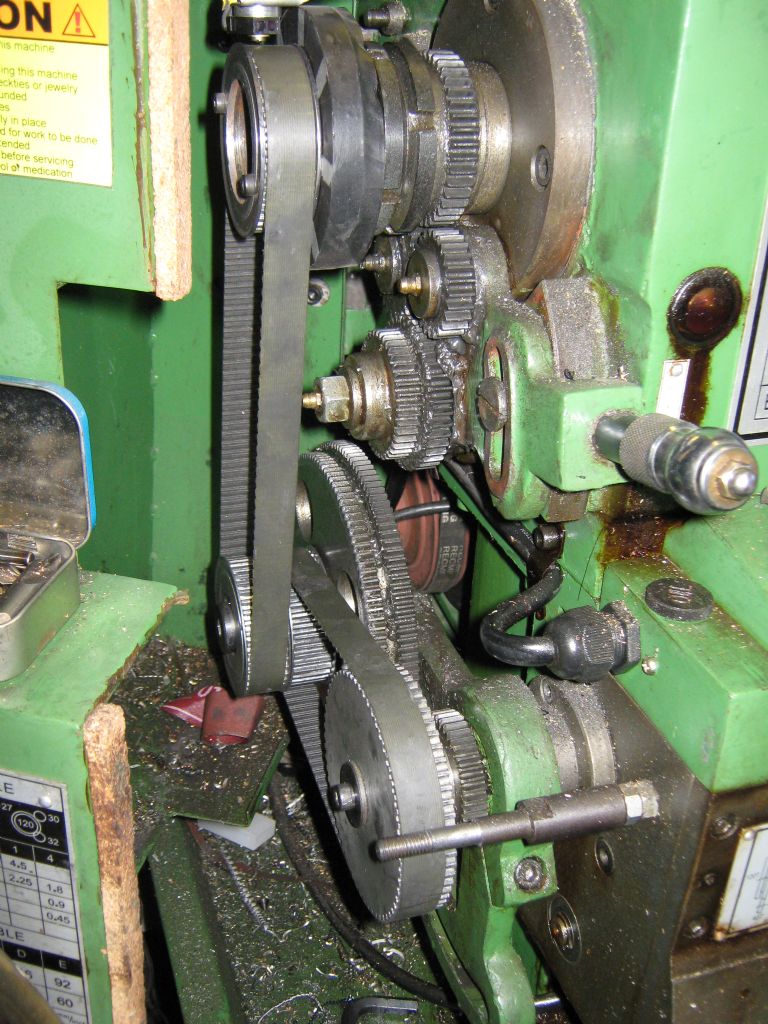

So my Warco BH600G is a very capable lathe however there are a few things i would like to look into changing and hoping people on hear have had similar ideas or indeed solutions. First of all my largest gripe with this lathe is the noise especially at high speed when then feed lever is engaged! My workshop isn't big and is very echoey which only over emphasises the noise this machine makes. Now i have been doing some research into this and have found a few possible solutions. The easiest is plain and simply putting sound deadening in the gear housing, re meshing the gears and using something called open gear oil? Apparently this dramatically reduces the ringing that i am getting so i have ordered some of that as it can't hurt. Then i started to look into the gears them self and considered making some plastic gears out of Delrin? Knowing that its a hard plastic with low friction properties i thought this could be a possibility? My only concern is the torque that the lathe puts out? I didn't know if it would essentially rip it apart as soon as it engages… I then thought about going to a gear specialist and having them machine a selection of helical gears as these are much quieter that conventional spur gears.

Another thought i had was converting the motor to a 3 phase motor with an inverter (not necessarily to make it quieter) but so i have more control over the the speed and being able to change the speed quickly and easily. The only problem with this is the cost and hassle for the small gain i will get. I priced up a system from Newton Tesla and it was around £500, I only paid £900 or slightly less for the whole Lathe! What i don't want to do is chuck a lot of money at the lathe when i could have just gone out and buy a Gear Head lathe that ticks all the boxes. Just wondering if anyone new of a cheaper or easier way?

The final thing i wanted to install was a clutch for screw cutting, again i have seen it done but it was a while ago and links don't work or the contents is no longer there. Just wondering whether this was something that people purchased and installed or made using drawings?

Any help and advise on what i could do would be great,

Regards, Steve

Steve Cole 1.