Posted by Stuart Smith 5 on 17/05/2020 22:13:20:

… I used to work at Electricity North West …

Stuart

Nothing to do with Robert's problem but out of idle curiosity I took some photos of a local installation which I believed to be split phase. Except looking at them I don't understand the wiring! May be due to missing details because the photos were taken with a zoom lens across private land, or because I don't know about power distribution!

The consumer is a farmhouse and outbuildings converted to four or five private homes. Power comes from a HV transformer on a pole about 100 metres from the buildings, and the LV feed is buried.

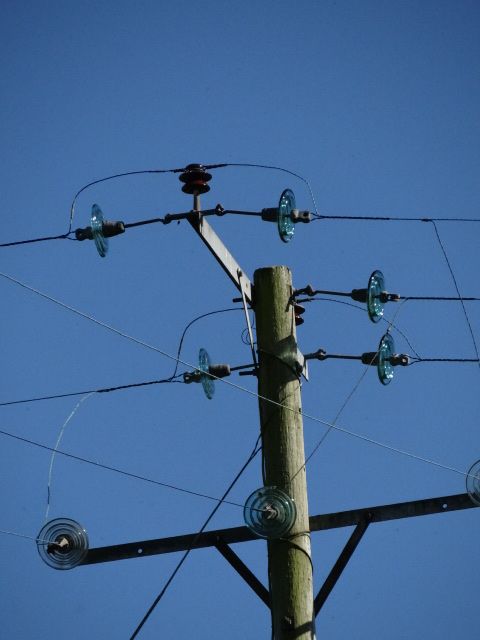

The HV end of the line is connected to the grid about 750 metres away:

The two wires on the left obviously take a single phase to the farm. The three wires on the right are incoming, and the cross-bar beneath takes 3-phase across a road to power a Sewage Farm. (Rural charm!) Anyway, it's clear that the farm only gets one HV phase. There's no earth or neutral.

Just outside the farm the two HV wires drop to a pole mounted transformer:

On the transformer's side can be seen 4 insulated terminals, which I guess go to two secondary coils. Although 3 wires are connected, (implying split phase with a centre-tapped neutral), the two straps suggest the secondaries are in parallel, ie single-phase to the farm, with one side earthed and neutral under the pole.

The wiring around the fuse doesn't help me much:

Again 3 wires are involved (four including the poles safety earth), but I can only see one fuse. Possibly there's another fuse hidden on the other side of the pole.

Does any of the wiring make sense to you Stuart? (Or anyone else!) Is this split-phase, or just plain single phase? Also, is the HV side 6kV or 11kV? I guess 6kV because the poles and insulators feel safe for lower rather than higher voltages, but it's just ignorant gut feel.

I've got a few books that explain power distribution theory but none explain how it's done in practice in the UK. (I feel like Sheldon in the Big Bang Theory; when Penny's car breaks down he understands thermodynamics, but has absolutely no idea how to fix a real engine!)

Dave

Edited By SillyOldDuffer on 23/05/2020 10:36:36

SillyOldDuffer.