Where did Neil ask that? Must admit I have not been following all the posts as they flow…

Well, I have 3 ( yes..) EMCO FB2 benc mills – One with DRO, one manual but fitted with a Jones&Shipman Beefy milling head, and the third fully CNC. I also have an EMCO V10 , completely renovated, bed re-scraped, new Head bearings, new leadscrews and fitted with my own design electronic leadscrew for imperial/metric threading and auto-feeds. Also has DRO, with a shop made rotary DRO encoder on the cross slide.

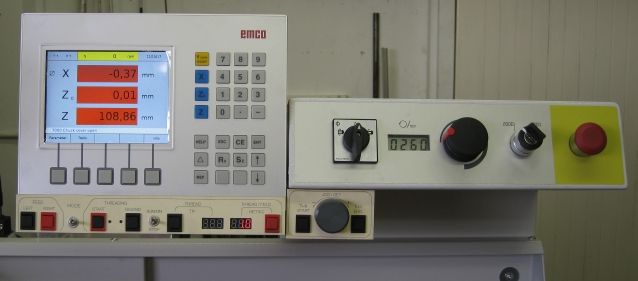

And I have a new EMCO 14D – well, going on 2 years old, but it has run 17 hours to date…(the V10P is the one that is always 'on'..) The 14D is also fitted with factory DRO and my Electronic leadscrew.

I have never had any issues with any of these machines – they are very well made, all slide surfaces fit very well, are scraped, and accurate. No jerkiness, no slop, parallel stuff is, and all a pleasure to use.

The V10P I have owned for 22 years, and refurbished maybe 2 years ago. The FB2's, likewise owned around 18 to 22 years.

The prices are well above the machines generally discussed, but the stuff is well built, well fitted and well thought out.

The FB2 does have a round column, which is perhaps its only detraction, but the FB2 fitted with the J&S head has a 2KW motor and I take 2mmDOC with a 65mm 6 insert cutter across the face of 'mild steel' no problem..The column seems to hold up.

The 14D arrived from Austria, on a 7 week boat trip to Namibia, then a truck from the harbour to my house, and was removed from the pallet, put in place and the EMCO rep did the accuracy checks with his fancy box of gauges and levels and micrometers and declared it in accordance with the factory release tests! He did not have to touch a bolt. The 14D is a VERY nice lathe.

Forgive me boring those who have sen it all before..to many times..

Joe

The V10P before..

and After..

The 14D

The lower panels are the added ELS on the 14D

FB@ with DRO

FB2 with J&S head

Anonymous.