If you still have the broken tooth consider cleaning the surfaces up properly and glueing it back in place with a strong cyranoacrylate adhesive. Maybe one of the flexy variety would be better. I'll not pretend 100% success but "I'll glue it for now to see this job out and fix it properly later when I have time." repairs have sometimes done well enough that later never came.

When it comes to chuck jaw projection beyond the body I was taught never go beyond the first step from outside in.

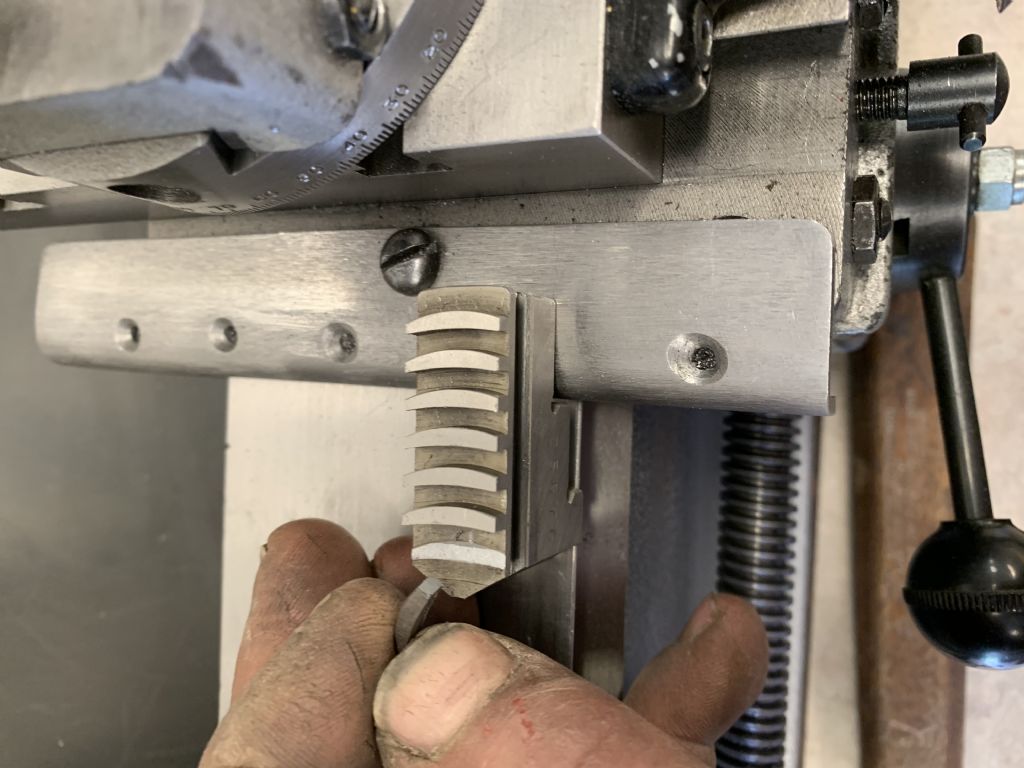

Which is probably more like three teeth engaged than two. Many of the better quality chucks have marks on the jaw to delineate maximum extension. The ones I have are in close agreement to the one step rule.

Some smaller chucks have rather skinny scrolls so best to check and, if need be, modify your maximum extension rule accordingly.

The scroll on the inexpensive, but unreasonably accurate for the money, Chinese 5C spigot mounted one I have is a good example of the skinny scroll. I got it with a 5C Spindexer for milling duties where a lesser grip is than required for turning is generally acceptable so not a major worry there. However my lathe has a 5C native spindle "taper" so it does get used on turning duties with the jaw projection rule tightened to less than half a step out maximum.

Clive

Michael Gilligan.

Michael Gilligan.