Gentlemen I'm not the sledge hammer wielding gorilla my original posting might have suggested, honest! .

.

I had read the thread that Simon Williams had suggested which is why I asked for advice. Having read what you all suggested I went out to the shed and:-

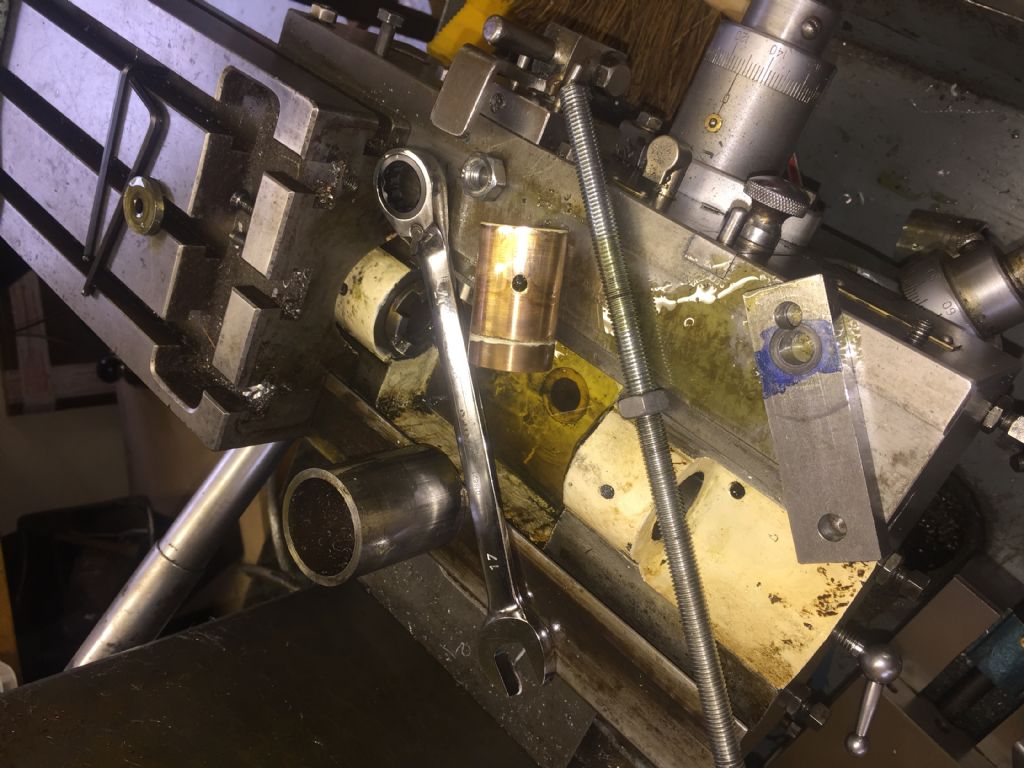

I had all the bits to do the job, I used 10mm threaded rod 'cos that's what I had. I even got the chance to use a fancy 17mm spanner that I bought in a panic in France a couple of years ago and never actually used. Wound away on the ratchet and bingo, easy peasy :-

I shall send it off to the Ebay chap from Cardiff for him to make me a new one. I'm not confident enough to have a go my self .

.

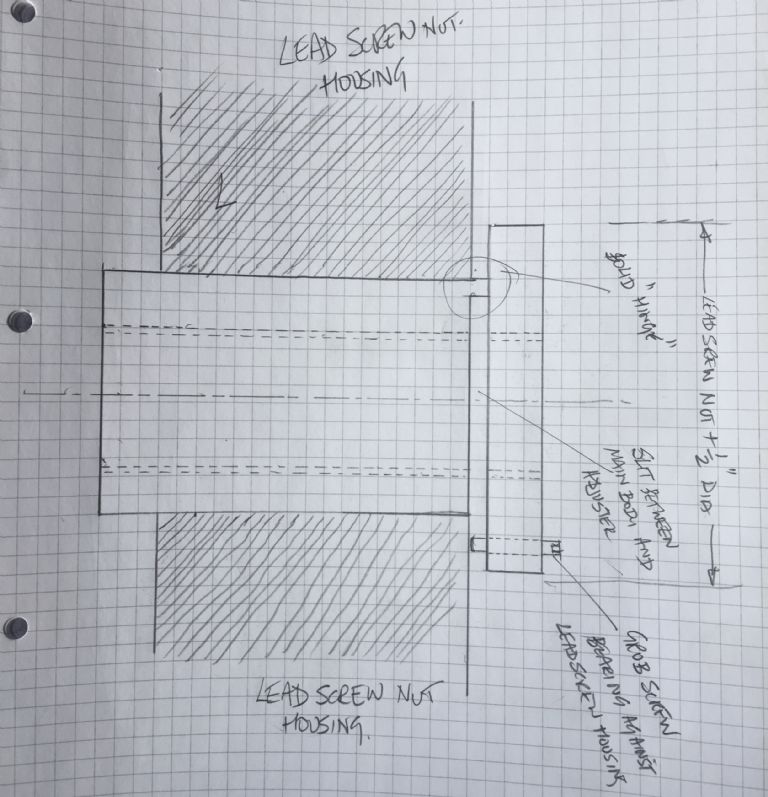

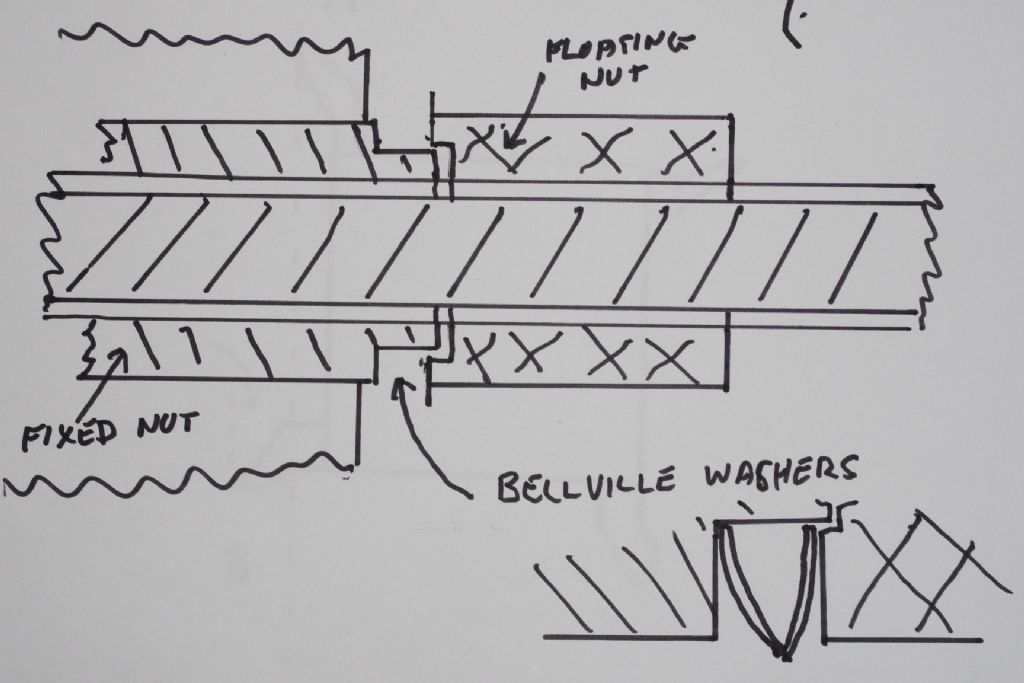

As Basyle suggested now is the time to make a back lash wear adjuster. I did one before on my Centec mill but I'm not qiute sure how to do it on a cylindrical nut, I thought I could some how utilise a bit of the old nut. Any suggestions?

The machine is serial number M2481 which believe makes it 1965 so the is some excuse for a worn nut!!

Thanks to you all for your prompt advice, it is greatly appreciated.

Keep smiling and keep safe.

old mart.