Returning belatedly this morning to my question "How do you tell a poster he's wrong", I found the thread locked, partly because it had picked up some comments on Jacobs Chucks! Thanks to everyone who replied to my question, and for providing a neat link to this thread!

On the subject of Jacobs Chucks I have one that absolutely must be tightened using all three holes. Drills come loose if it's not done, and it was unnecessary when the chuck was new.

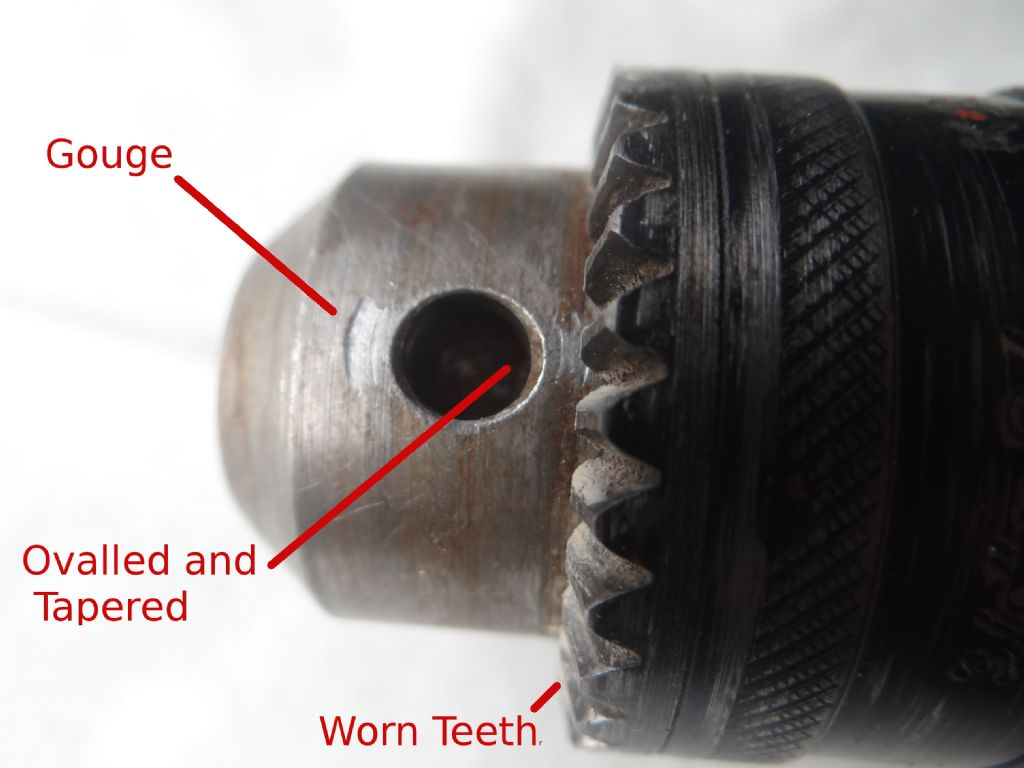

Here's photographic evidence of what I think is going wrong

Not too obvious in the photo is that the teeth are worn. Even when new these teeth did not mesh particularly well with the key; over time this has got worse, and the key sometimes rides out..

It can be seen that turning the key has gouged a trench in the body of the chuck. This suggests that tightening the chuck involves misplaced significant force. (And perhaps that the steel of this chuck is soft.) Even more suggestive is damage to the hole itself. Use has enlarged the hole and reshaped it into an oval. It has also developed a noticeable bell-end.

This wear is bad news, because the key no longer seats properly in the hole, and the misplaced torque makes it difficult to tighten the chuck. Pushing the key to close the gap helps, but not much.

It is only possible to tighten this chuck properly by using all three holes progressively.

So I suggest, this is an "it depends" question. It probably doesn't matter if a brand-new well-made chuck is tightened by putting the key in a single hole. As there's no slop, the turning forces are sufficient to tighten the chuck.

But no matter how well-made, that chuck will eventually wear.. Once that starts we have a new situation that gradually comes to dominate. Wear causes the forces applied to the chuck to tilt causing wedging in addition to the desired turning action. Moving the key from hole to hole would tend to break the wedge, and each movement would allow the chuck to nip up further. Now having three holes matters.

My hypothesis is that chucks are provided with three holes to extend their effective lives. A chuck with one hole would wear out quickly. Three holes are better than two when it comes to evening out wear, and four would be a structure weakening overkill.

I suspect but can't prove, that my chuck is also worn on its "axle". It certainly has 'run-out' that might be worse than when new. Again this would cause a tilt tending to increase wedging.

If I was clever enough I'd attempt a mathematical analysis. I'm not! Anyone know if Fusion360 could do it?

Dave

Hopper.