Posted by Mike Poole on 26/10/2019 21:51:36:

The passion for dimensioning drawings for models using fractions of an inch is I feel ridiculous, a sixtyfourth of an inch is 0.015625 so most people are going to call it 15 or 15 and a half thou and the rest is lost using practical tolerances and home workshop equipment. A set of gauge blocks is not able to accurately produce a size involving a sixtyfourth but for practical purposes it’s not going to matter but it’s going to bother anyone with CDO ( that’s OCD but with the letters in the right order).

Mike

Well, in the good old days you could buy a set of gauge blocks which included extra blocks (about 8 I think) covering common fraction sizes.

However, I wouldn't go so far as to describe fractional inch drawings as 'ridiculous'. Archaic is enough! Whilst there are good historical reasons for fractions in drawings, they've been pushed out by thou and mm.

Before about 1900 most people dealt with simple divisions. Ordinary life is full of them – sharing out food, booze, money, fuel, etc. Fractions deal with ordinary situations so effectively that decimal notation wasn't even taught to anyone receiving a basic Victorian education. Decimals were rarely needed in workshops.

Before precision engineering, workshop measurement was dominated by dividers. Dividers allow dimensions to be captured and transferred such that parts can be made without measuring at all. Dividers also divide: it's remarkable how accurately halving can be done by eye, hence the popularity of fractions in powers of 2. Dividing is one of the foundations of the imperial system, giving us 1/4" 1/8" and 1/16", all handy in carpentry, cobbling, tailoring and many other trades.

In metalwork 1/64" is about the best that can be done by eye, and this was the highest standard of professional accuracy up until about 1850. But then the fractional system began to break. As technology advanced it became ever more obvious that most problems aren't conveniently represented by fractions. One example is Letter and Number drill sizes, basically odd diameters needed to plug gaps in the 1/64" system. Although the axles of a locomotive can be spaced perfectly by applying simple fractions, the relationship between firebox size and boiler size, and boiler and cylinder volume, and cylinder volume and piston stroke are less obvious. And the design detail needed achieve speed, reliability and fuel economy is important. So mankind moved from craftsmanship and proportions based on individual experience to engineering. Engineering proportions are calculated by reference to scientific method.

Fractions deal extremely well with anything involving integer ratios, but they are awkward for everything else. Decimals don't run out of steam in the same way and have other advantages. For example, it's not obvious if 73/112 is larger or smaller than 74/113 : decimal representation makes it plain. And being more general means decimals simplify many calculations and measurements for instance by allowing people to use slide-rules and digital calipers.

Because of all this, fractions – though still important – have been largely displaced by decimals. As soon as micrometers became available, Imperial Engineering started shifting to thou. Later the advantages of working to tolerances became apparent and tenths became important. This wouldn't be possible were it not for ultra-precison gauge blocks because tool-rooms making jigs, fixtures, and inspection gauges need to be about 10 times more accurate than anything done on the shop floor.

I suspect most people faced with a fractional drawing convert most dimensions into thou? Does anyone produce new drawings with fractional dimensions?

Not that I care much – I prefer to work in metric!

Dave

Nigel McBurney 1.

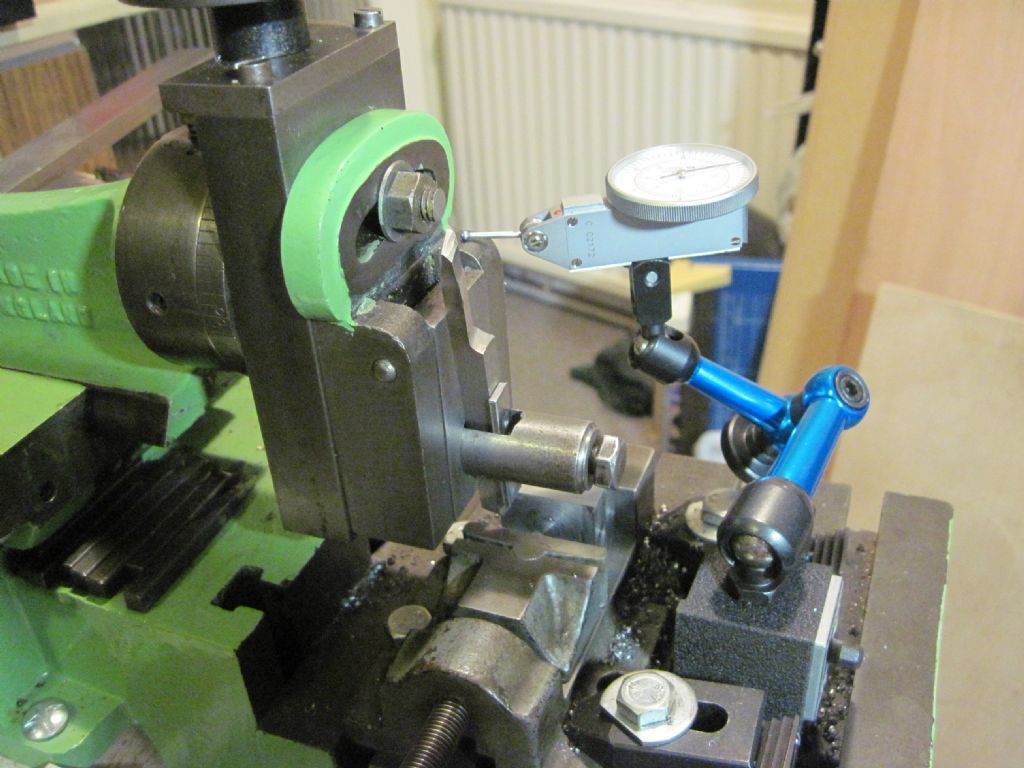

if machining a surface with shoulders steps & troughs they are very handy even if it becomes necessary to alter the angle of the tool itself to reestablish tool height with a gentle touch on the appropriate block, I have a shaper gauge which came with the machine.

if machining a surface with shoulders steps & troughs they are very handy even if it becomes necessary to alter the angle of the tool itself to reestablish tool height with a gentle touch on the appropriate block, I have a shaper gauge which came with the machine.