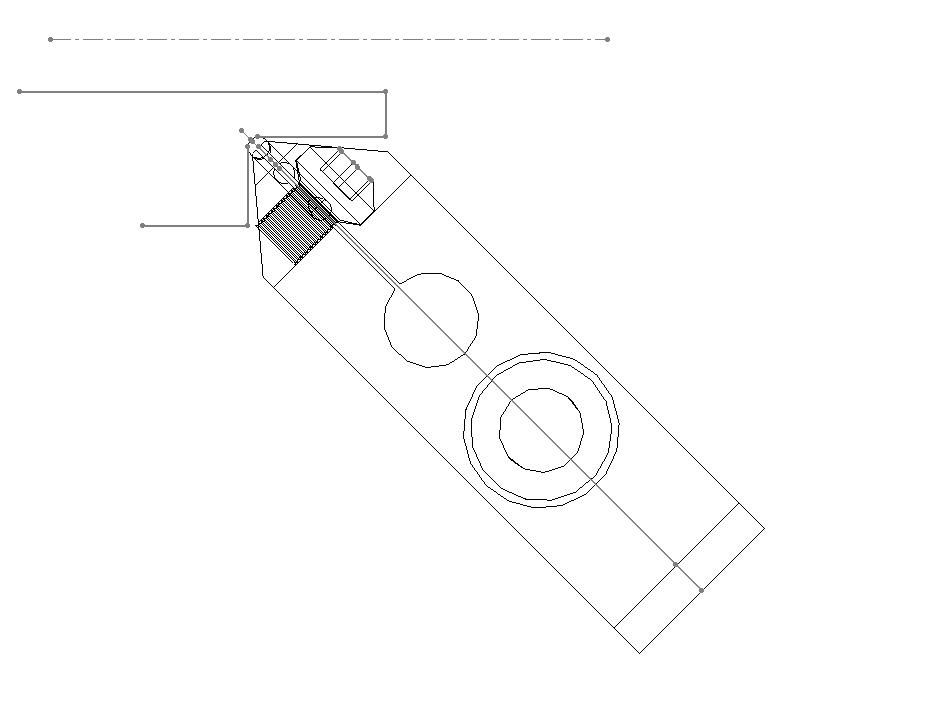

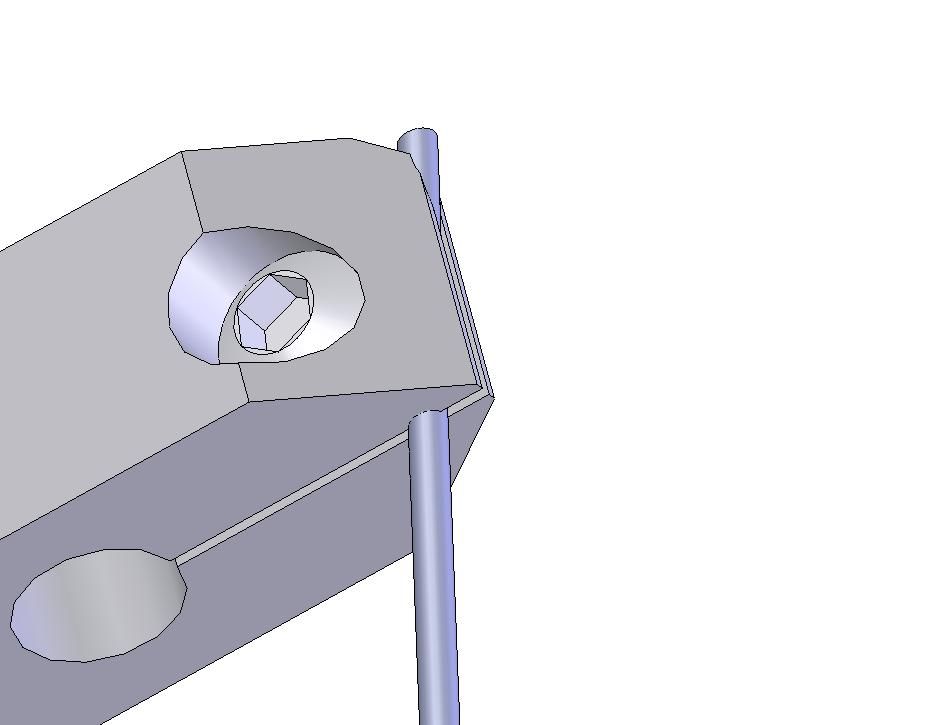

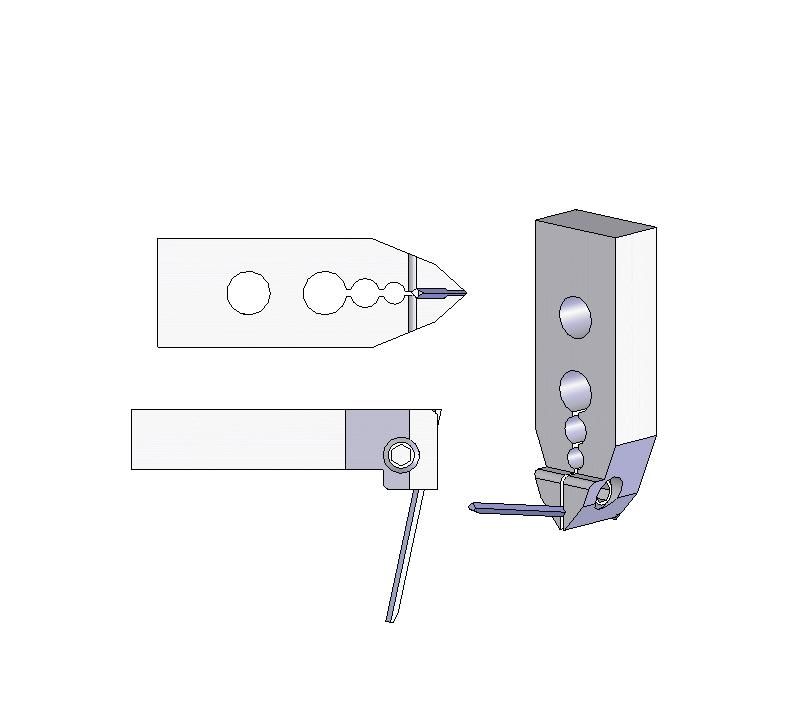

Ha, I am being overtaken by posting events! Niels, to respond to your old post – it is gratifying to see that your CAD images are more or less identical to the holder as I have it – I made the nose angle 85 degree, but will make it narrower on the next one. I have filed it for easement and now need to experiment to see how tightly I can approach from the side.

Howard, I find that the 2mm bit (as I currently have it ground and held) is limited to a useable cutting depth up to about 0.25 mm – adequate for the Hobbymat, but I think there are probably better choices for bulk stock removal – it is possible Niels can achieve better, not least because he has spent far longer in refining his design, and has a more solid platform from which to work.

It strikes me that CAD may hold the definitive answers on cutting depth, which will surely be tied to the logical mathematics of an acutely-sectioned cylinder?

As to setting, in practice, I find that because the cutting edge is plane and somewhat reflective that orientation is easily established by eye and intuition, although being plane, it ought to of course respond to the attentions of a small but easily constructed setting jig.. Another thing to get round to!

Slitting saws – I think I must have started to use them whilst I was unaware of the dangers, and so they do not cause me any concern – use a speed at the lower end of the required m/m, feed by hand gently until the teeth are fully engaged in the slot and thern you can up the feed rate just a little to keep it cutting cleanly – maybe you know that "hissing" kind of noise when steel is cutting nicely – like that, and like all sawing, best results by not pushing too hard, just each tooth cutting off a nice chip.

For a small job, I'd rather go slow and not use oil, than use oil and have the chips turn to a sticky mush in the slot, better to keep them free to exit. Never use CT90!

The centre height is about 10.5 above the slide, but accurately measuring is first job of the morning!

Sincere thanks for your advice so far

DiogenesII.

![wp_20200606_001[1].jpg wp_20200606_001[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866052.jpg)

![wp_20200606_003[1].jpg wp_20200606_003[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866054.jpg)

![wp_20200606_002[1].jpg wp_20200606_002[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866053.jpg)

![wp_20200606_005[1].jpg wp_20200606_005[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866056.jpg)

![wp_20200606_010[1].jpg wp_20200606_010[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866124.jpg)

![wp_20200606_009[1].jpg wp_20200606_009[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866123.jpg)

![wp_20200606_007[1].jpg wp_20200606_007[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866122.jpg)

![wp_20200607_001[1].jpg wp_20200607_001[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866264.jpg)

![wp_20200607_004[1].jpg wp_20200607_004[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866265.jpg)

![wp_20200608_002[1].jpg wp_20200608_002[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/866300.jpg)