After posting a question about cutting a m10 thread, some of you suggested macking a tail stock die holder.

So here goes.

This project was born from needing a tool to make a tool. As is so often in the home workshop.

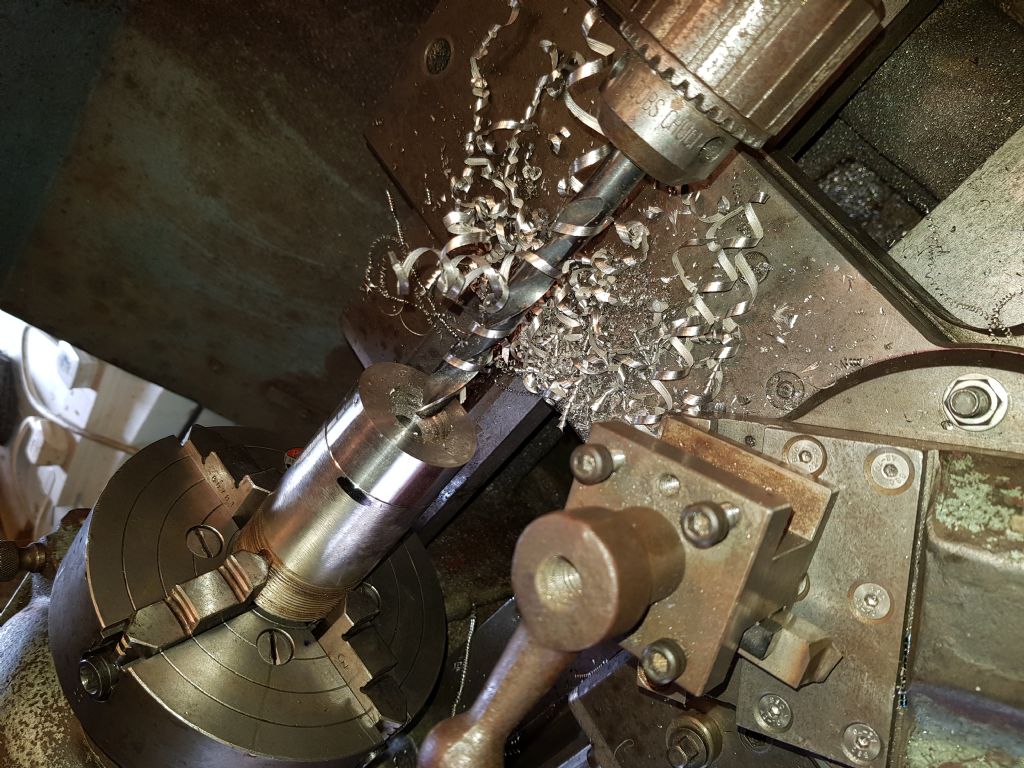

Anyway i was making a toolpost mount and needed to cut a m10 thread. Didn't have a die so i orded one. When i came the OD was 1.5 inches. Didn't have a die holder big enough. Order one no no make one. So i started to make one out of god knows what HARD HARD steel i had. As i was in no rush and not having used the 4 jaw cuck i dug it out and after 10 minutes faffing about got in running within about half a thau. Good enough for me. Some pictures

Started out by turning the OD to what seemed to be a decent size to accommodate to handles.

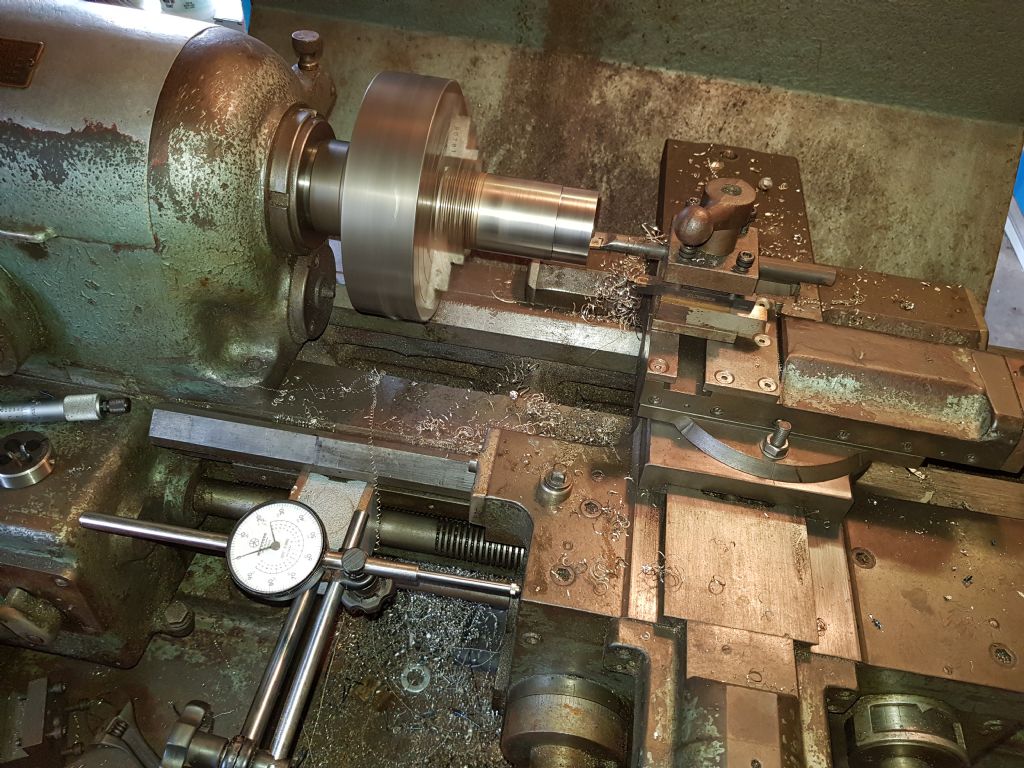

Drilled and bored out the the ID to a perfect fit.

Using the DTI to get to the correct depth.

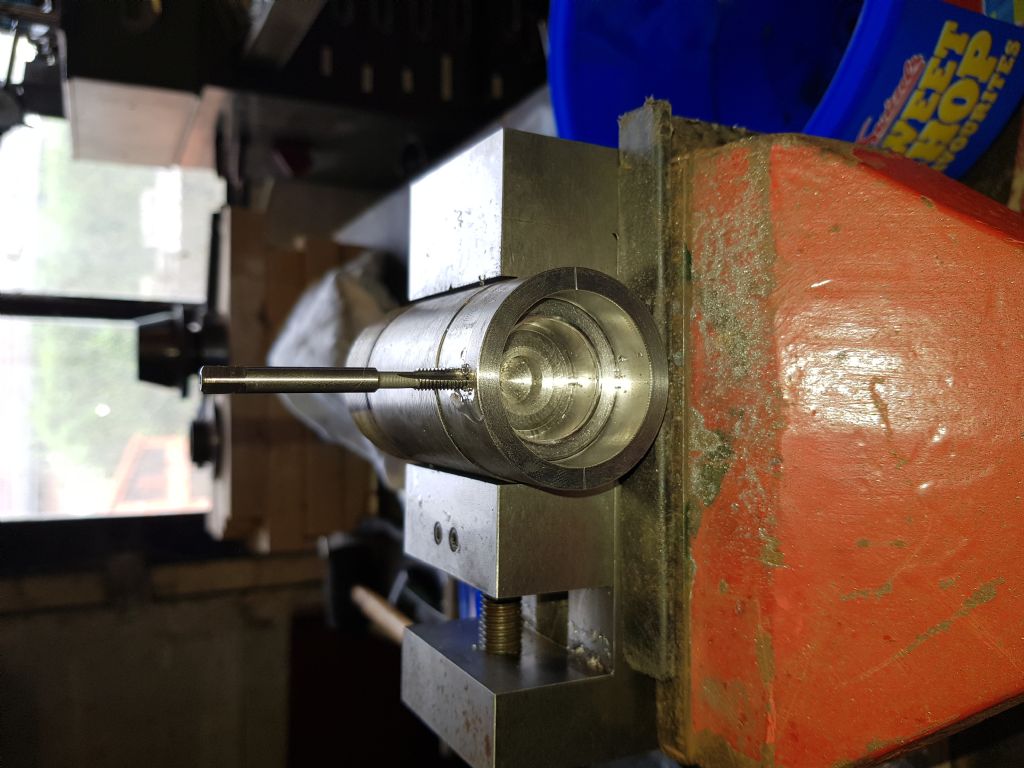

In this picture the die isn't pushed all the way in. When it is its perfectly flush.

Then marked out, drilled and tapped the 3 securing / adjusting screw holes.

The plan was to cut it off the length, drill and tap 2 holes 180 from each othe and add handles. Job done.

Well not so. After taking advice from forum members its back in the 4 jaw running true and ill drill and bore through the middle and turn it in to a tail stock die holder.

Is my skills are at the beginer level im not going to make a mores taper arber. My plan is to bore the through hole 1 or 2 thou over the OD of my tail stock and use the extended tail stock as the running arber if that make sense.

More progress pictures to follow when i get back in the work shop. Hope you enjoyed read the exploits of a beginner and any advice more than welcome.

Thanks

Steve

not done it yet.

. The mandrel is 2MT and there is a pin (visible near the end of the parallel shank) which engages in a slot in the sliding part of the tool with a rotating circlip to 'lock' the tool onto the slider. I have a rack operated tailstock so engage the die onto the workpiece whilst holding the lever vertically. The apron needs to be clear of the handle to allow it to rotate about 90 degrees (towards me) to disengage the clutch. I always thread in 'back gear' to give plenty of torque and to allow for slow threading. The nice part is you can thread upto a shoulder with no concerns as the tool when abutting the shoulder turns the 90 degrees and disengages instantly. Reversing the lathe lifts the lever back tothe vertical and the die holder re-engages and winds the die off. The materials I commonly cut are A286 stainless and T614 Titanium. The lever is long enough to be able to comfortably hold by hand whilst cutting the thread.

. The mandrel is 2MT and there is a pin (visible near the end of the parallel shank) which engages in a slot in the sliding part of the tool with a rotating circlip to 'lock' the tool onto the slider. I have a rack operated tailstock so engage the die onto the workpiece whilst holding the lever vertically. The apron needs to be clear of the handle to allow it to rotate about 90 degrees (towards me) to disengage the clutch. I always thread in 'back gear' to give plenty of torque and to allow for slow threading. The nice part is you can thread upto a shoulder with no concerns as the tool when abutting the shoulder turns the 90 degrees and disengages instantly. Reversing the lathe lifts the lever back tothe vertical and the die holder re-engages and winds the die off. The materials I commonly cut are A286 stainless and T614 Titanium. The lever is long enough to be able to comfortably hold by hand whilst cutting the thread.

Threading up to a face is particularly interesting.

Threading up to a face is particularly interesting.