Posted by Andrew Johnston on 05/06/2020 08:23:01:

… May be SoD has more influence than we realise, and we should be careful in case the boys call round for a 'chat'.

Andrew

Absolutely agree. SoD is infallible! My mum thinks he's gorgeous too…

Fantasy over. The claim in favour of grinding comes from Industry taken as a whole. As manufacturing developed over the centuries, every effort has been made to replace toothed metal cutting with some other process. Either because the alternative is cheaper or is more accurate or both. Casting, Rolling, Stamping, Extrusions, Gas Axe, Lasers, Water Jet, Spark Erosion, Chemicals, Forging, Grinding and many more techniques are in the game.

Possibly the forum's deep interest in lathes, milling machines, files and saws leads us to lose the big picture? Whilst 'our' methods dominated industry into the early 20th century, not so today. Time marches on. Not only are more production processes available now, but machinable metals are often replaced with plastics, ceramics, and difficult metals that don't mill or turn well. For that reason manual lathes and mills are rarely found on production lines.

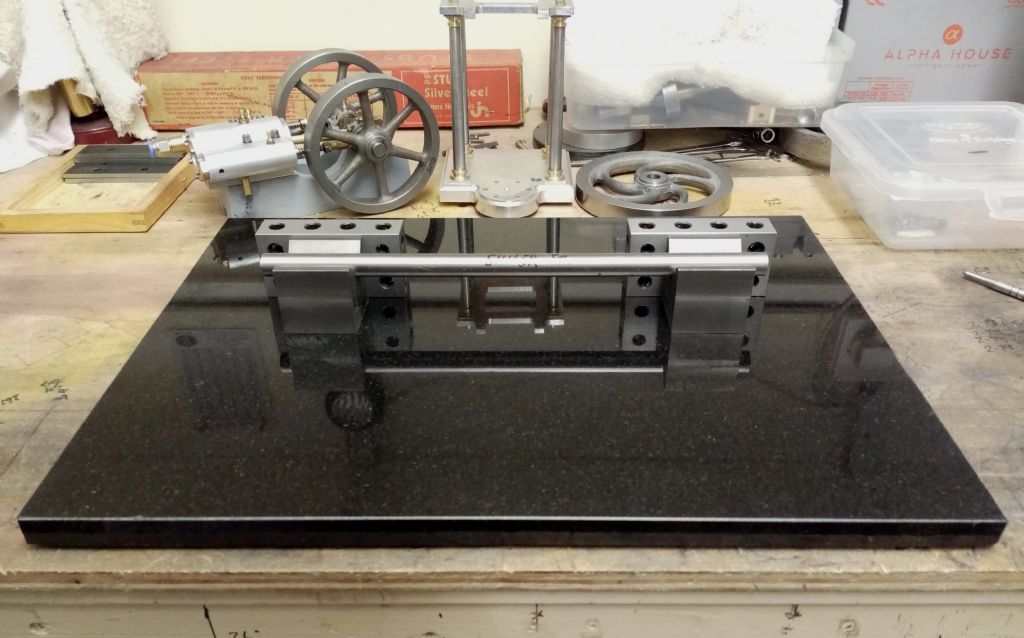

Have a wander round and ask how each product in the home was made and how much of it involved a lathe or milling machine. Take cutlery: there are nearly 8 billion people on the planet and most of them use knives, all made by rolling, stamping and grinding. Many other common objects avoid cutting too. Screw fasteners are rolled. Precision threads are ground. Opening up a printer, TV set, vacuum cleaner, fridge, boiler or even a car engine won't find many milled or turned components in it. Most of my workshop tools are ground, including the lathe's ways and the milling table.

Plenty of counter examples because toothed cutting is still the best way of tackling many jobs, but it's not nearly as ubiquitous as it used to be. Any Production Engineers on the forum?

Dave

Ron Laden.