Not sure, how tall you want the Height Gauge, or how big the Surface Plate, nor how much you are prepared to spend..

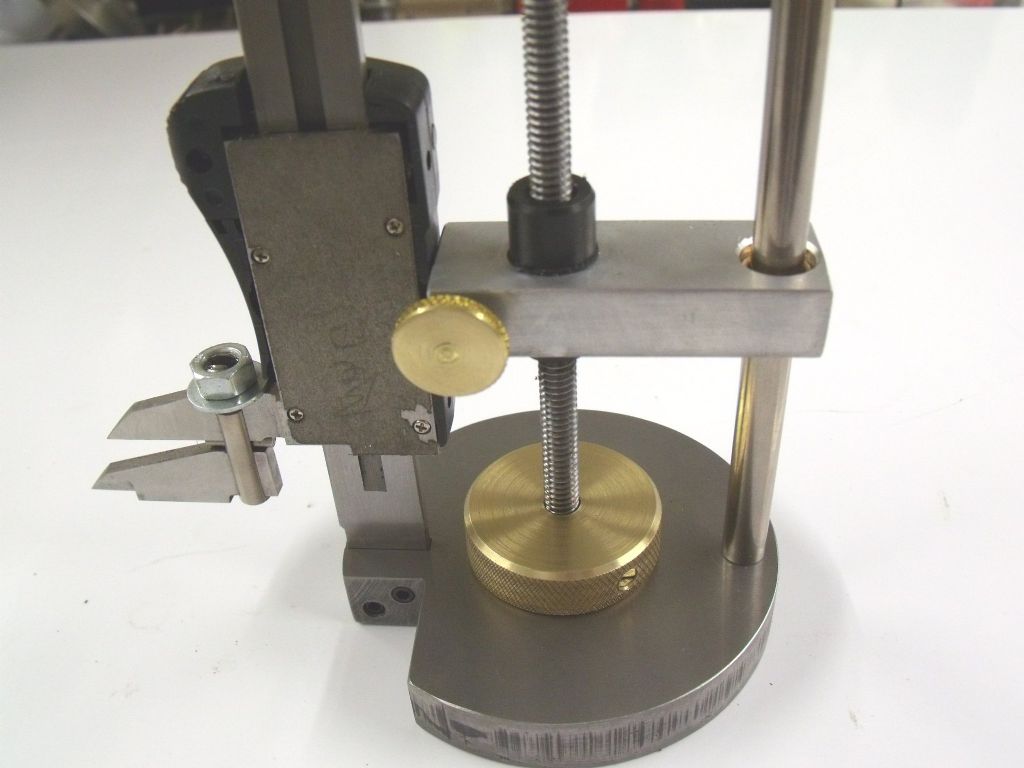

HEIGHT GAUGE

If you are going to buy new, Arc Euro sell three Digital Height Gauges, a 150 mm one at £39.10, an 200 mm one at £79.31 and a 300 mm one at £94.03

If you buy secondhand, (possibly a bit late now, but when Industry changed over from Imperial to Metric, you could find Imperial ones in quite good condition fairly cheaply, because they were no longer wanted. My Height Gauge was condemned, because it had a 0.002" error over 18", which is acceptable for the work that I do! )

SURFACE PLATE

Some years ago, I made a surface plate for The WaterWorks Museum in Hereford., 18" x 24" x about 1.5" thick. A Kitchen Work Top / Grave Headstone maker, in Wisbech, cut me a piece of granite for £30.

You might be able to find an offcut cheaply, and make a base to suit.

If that seems expensive, an industrial, Mitutoyo 6' x 4' x 6" would have set you back over £3K at the time!

So, relatively, I got a bargain; for less than a third of the price an Industrial quality one.

I made up an angle iron frame, with a leveliing screw at each corner. The legs extended above the frame, to provide a loose location for the plate. On this frame, was placed a plywood support which was coated with a moist layer of plaster / Polyfiller, onto which the marble was placed. Being fluid, the filler could flow, so that the granite was uniformly supported, and not stressed.

Finally, a plywood cover was made, varnished and fitted.

An Industrial Surface Table, like the one mentioned above was ruined, by being leaned at an angle against a wall.

It sagged and bent!, Hence the need for a table to be stress free, as much as possible.

(No point in trying to work to greater accuracy than your measuring equipment, which includes the flatness of the Surface Table )

HTH

Howard

.

Ron Laden.