Posted by Ramon Wilson on 24/07/2022 14:46:51:

So when do we get to which locknut nut goes on first !!!

I have quite a few books on industrial stationary engines and it's quite an eye opener when you look at the various images to see where the 'right' way is used – quite rarely in fact.

Same with washers – I prefer not to use them but it's a good point on spoiling the paint however a tip to help prevent that is to chamfer the lower corners of the nuts before fitting. Usually quite successful providing it's not 'graunched' up home

Nice work Doc – get to it

Thanks Ramon.

I was looking at a .pdf on steam engine design this week (I think Jason linked to it on my Twin Victoria info thread last year). Looking at engines at our local museum, and a traction engine rally last month, there are examples of washers, locknuts etc being used or not used. Has to be said that washers don’t seem that common at all though.

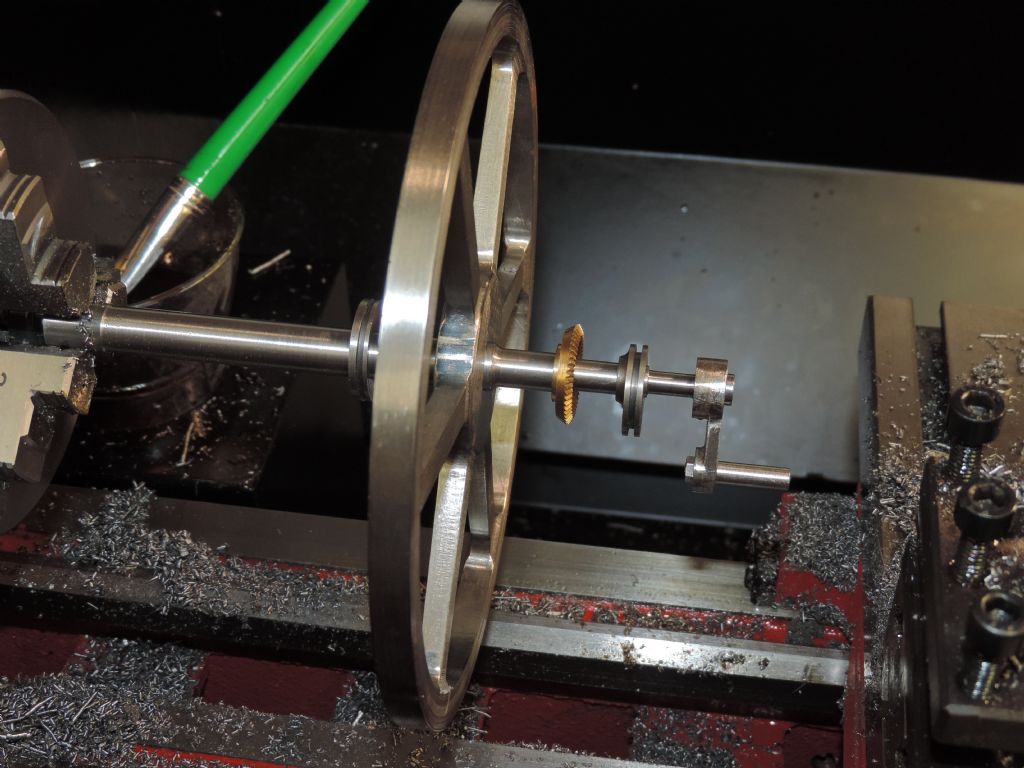

I’ll also work on a drawing for the crankshaft. It looked at it in detail yet, but perhaps steps for the flywheel, governor pulley (on one side), eccentrics, bearings and finally the cast webs?

Id like to use a thin flat belt for the governor drive. Ideas anyone have a supplier? I was going to go for a gear drive, but a flat belt will look ok too I think.

Question on split bearings: once removed after finishing, does the film of solder potentially make the bearings undersized in one axis?

Will be no progress next week – off to deepest darkest Pembrokeshire tomorrow for a couple of nights on Skomer island nature reserve. I wanted to get the drawings ready for when I get back though.

Thanks.

JasonB.

JasonB.

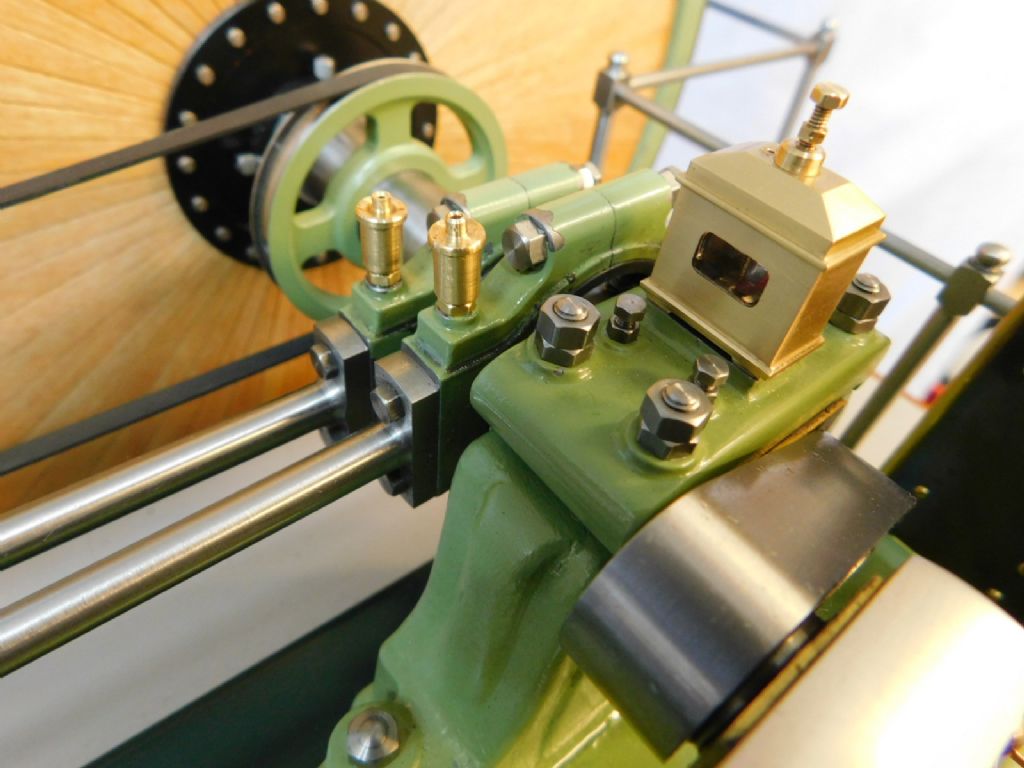

![dscn0069[1].jpg dscn0069[1].jpg](/wp-content/uploads/sites/4/images/member_albums/51477/911581.jpg)

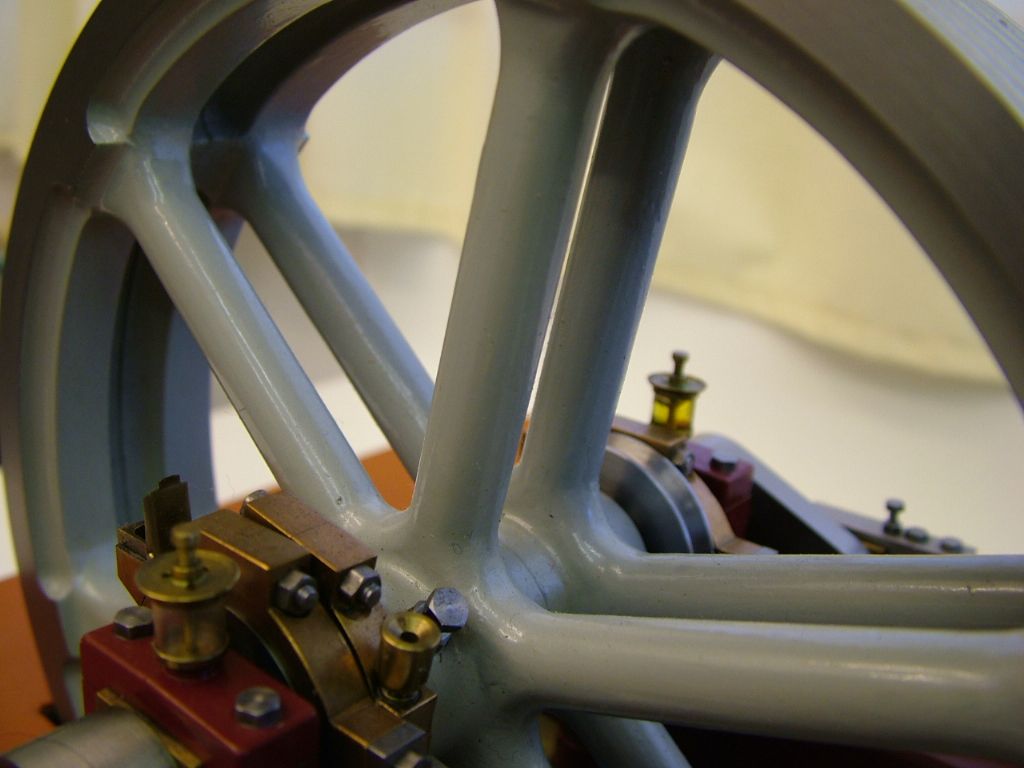

![dscn0070[1].jpg dscn0070[1].jpg](/wp-content/uploads/sites/4/images/member_albums/51477/911582.jpg)

![dscn0071[1].jpg dscn0071[1].jpg](/wp-content/uploads/sites/4/images/member_albums/51477/911583.jpg)