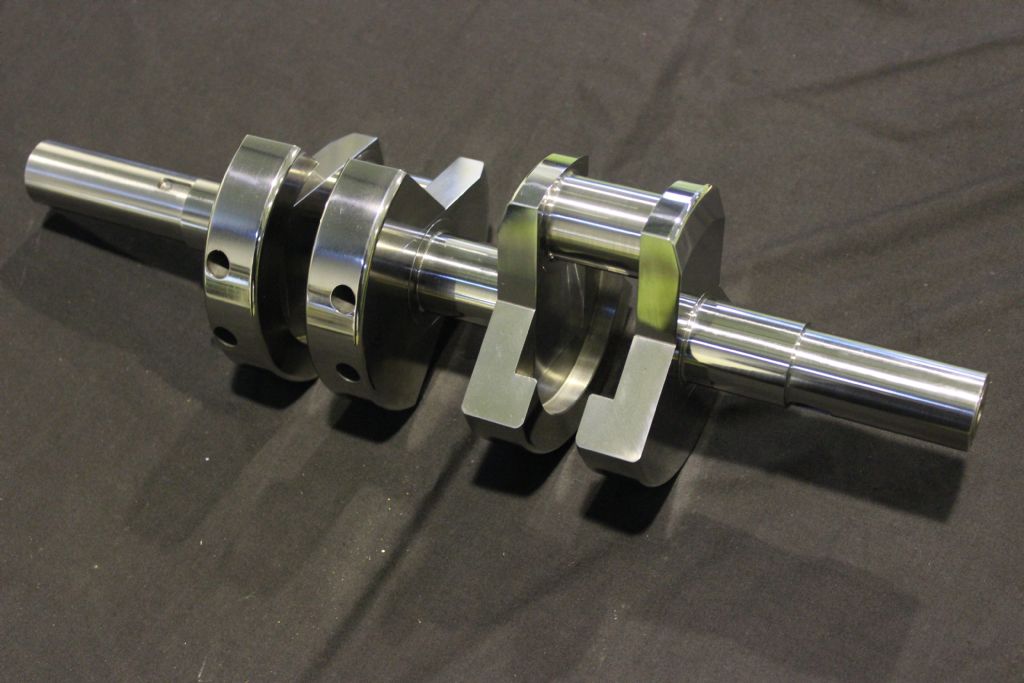

I used a spheroidal graphite casting for the crankshaft for my steam launch. This depends on having a reliable foundry that can do SG iron, but makes for an easier job with less material to be removed than cutting from solid…which I have also done for smaller shafts.

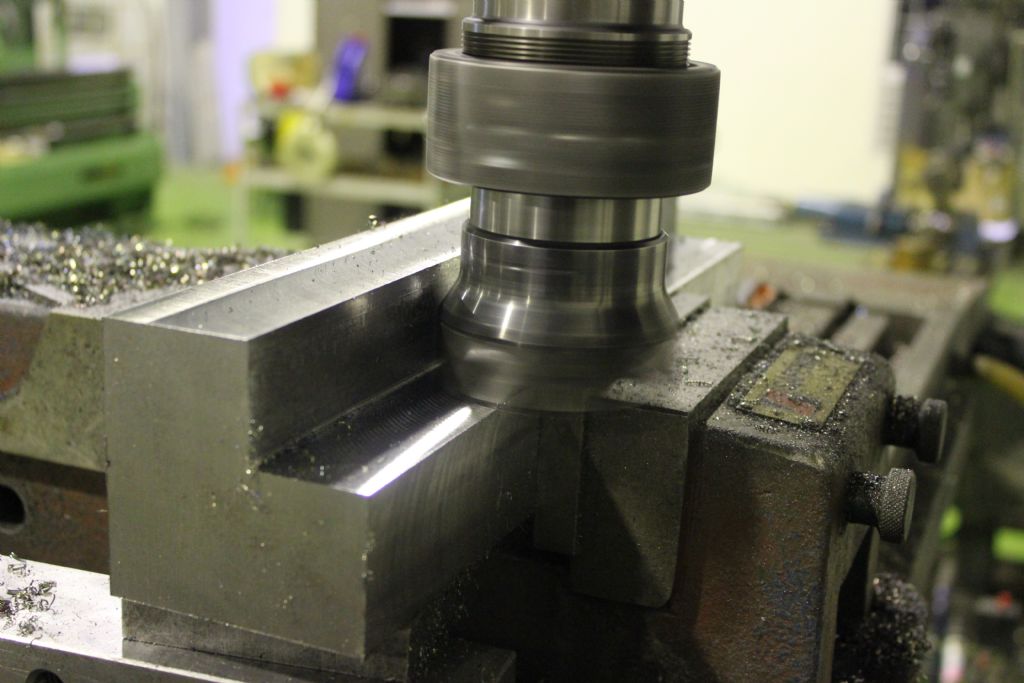

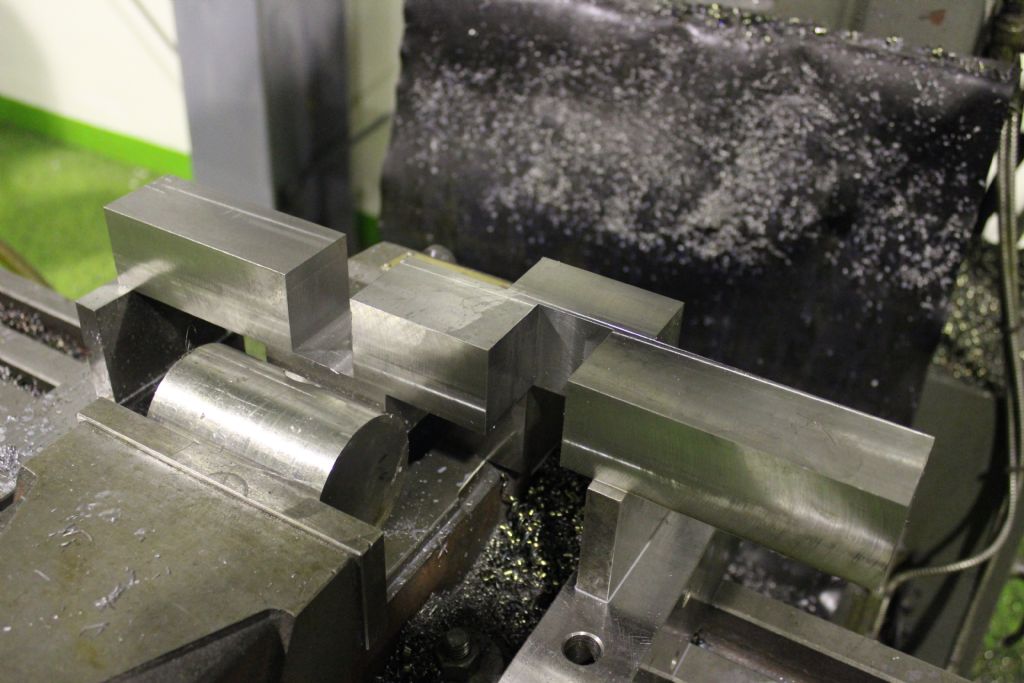

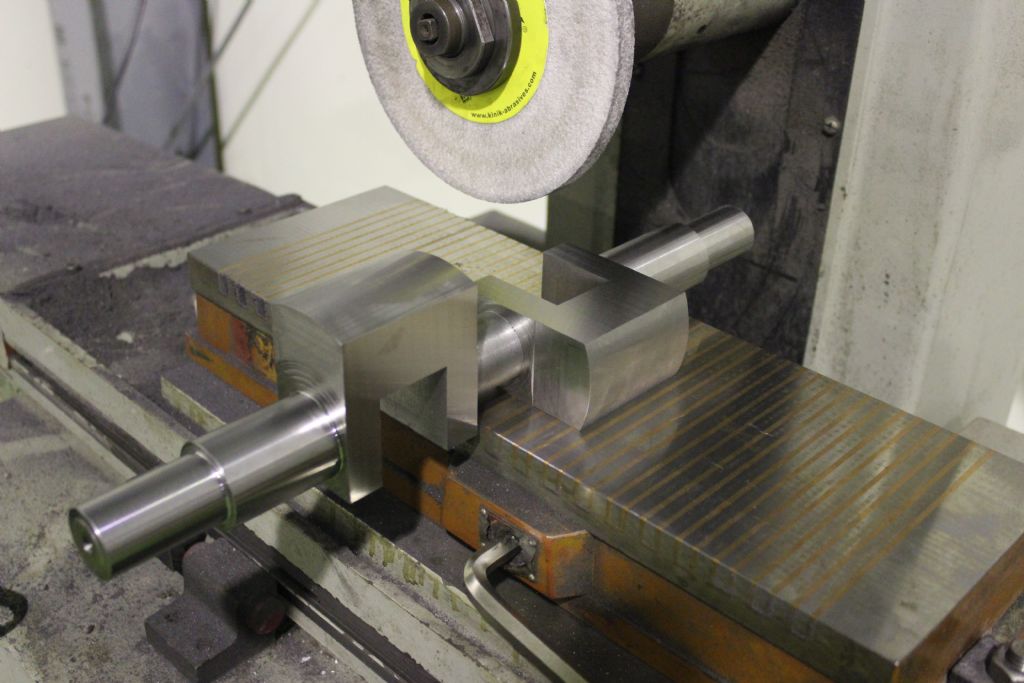

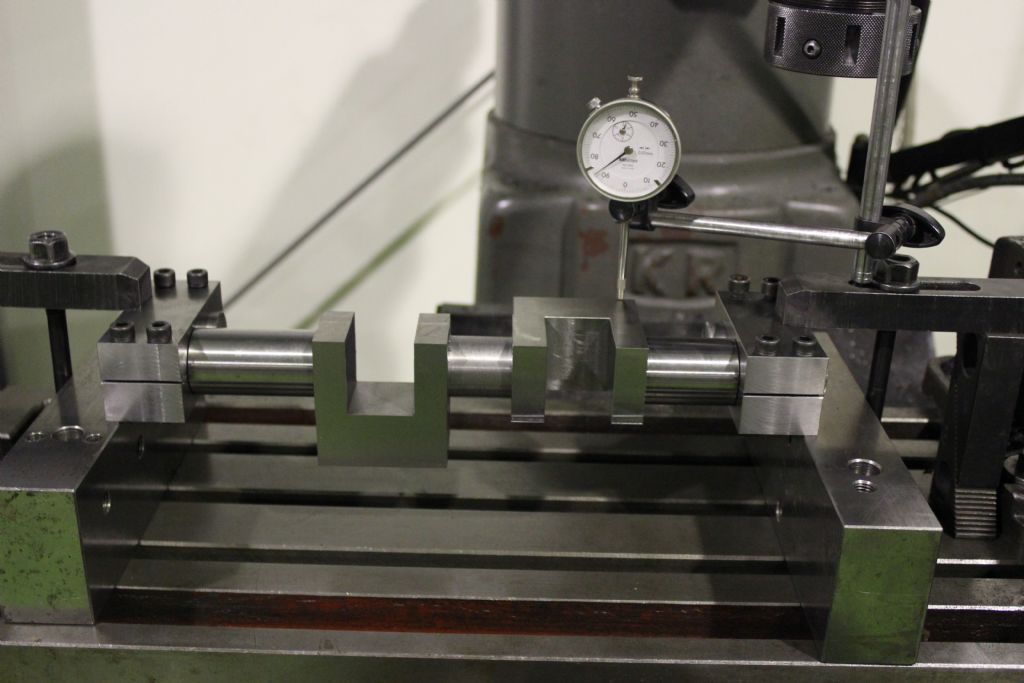

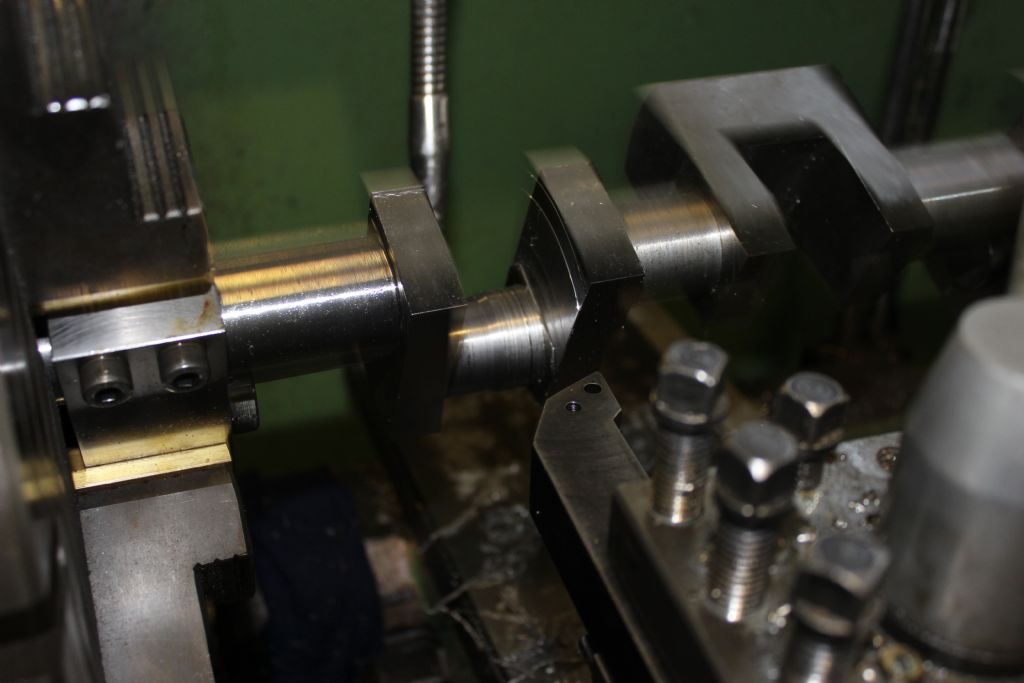

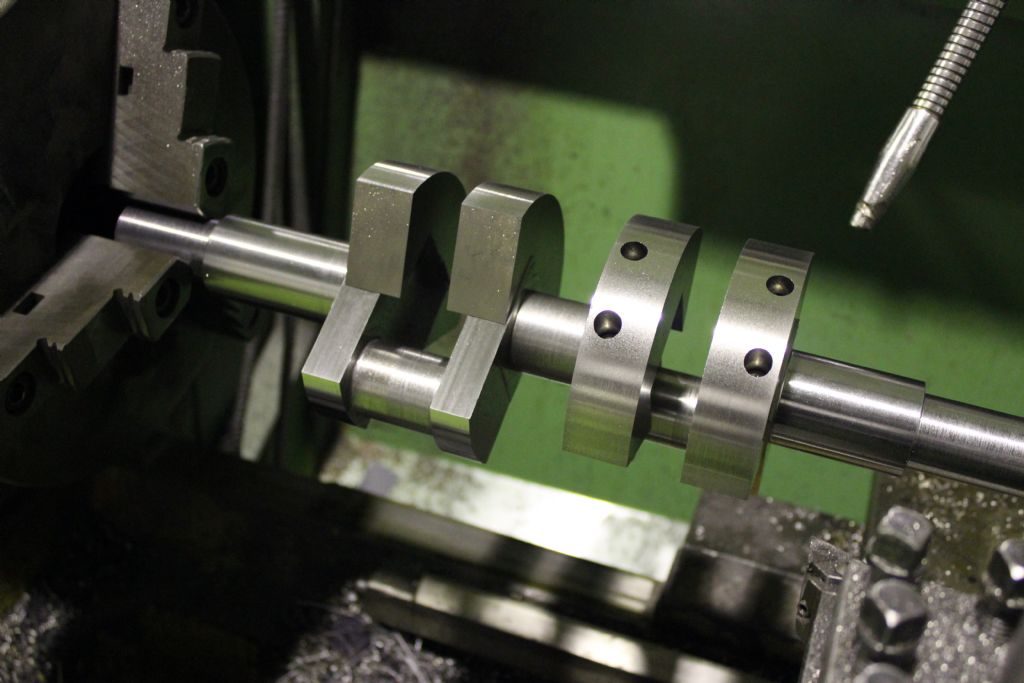

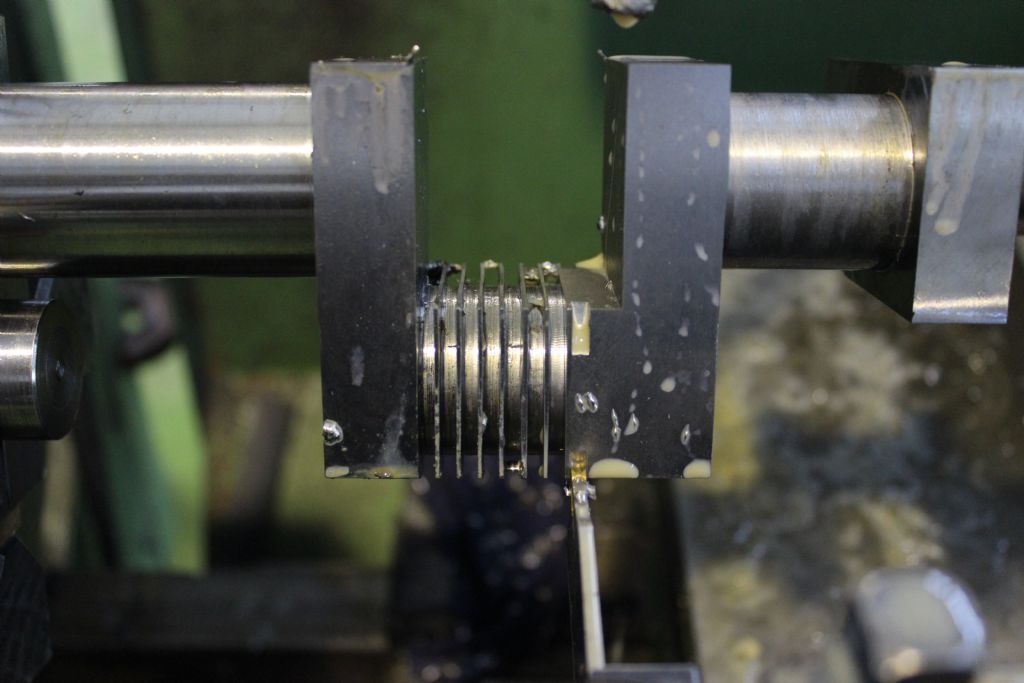

I made up a pattern with a bit of allowance and with the crank webs filled in. The offset pieces were also provided on the ends. Almost all of the machining was done in the milling machine with the shaft held between centres, as was done with the crankshaft in JasonB's link. This is a good way to machine shafts, suggested many years back by Professor Chaddock. I described it in an article in ME a few years ago. I used chain drilling and the bandsaw to remove as much of the excess in the webs as possible. When I finished, I was able to test the material by putting a piece about quarter of an inch thick by an inch wide and 2 or three inches long into the vice and hammering it. It bent to right angles after many blows, before finally starting a crack on the outside of the bend, but did not break off. So the material does not behave like cast iron and is very suitable for a crankshaft. You do need a reliable foundry because the SG effect is obtained by adding something to the molten iron as it comes out of the furnace, and if it is left too long before being poured it will revert to behaving like ordinary iron. After milling to slightly oversize, my shaft was ground to finish by an automotive machinist.

The 6A shaft is not heavily loaded compared to automotive shafts, so you don't really need high tensile steels.

John

Michael Gilligan.

Michael Gilligan.