I am glad that people are slowly coming to the conclusion that the question is unanswerable as posed.

For a given area of material, anything other than a regular shape (circle, equilateral triangle, square, etc.) can be made to have an almost infinite second moment of area.

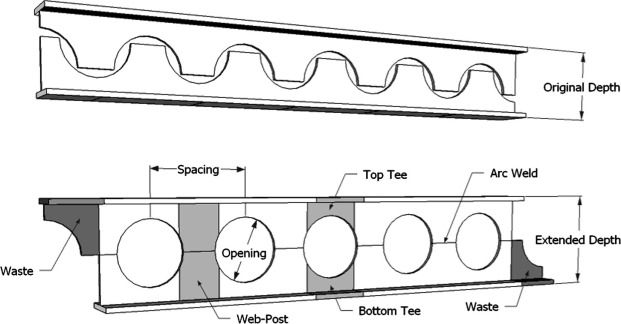

Take the I-beam, for example. I read that gold can be hammered to 4 millionths of an inch thick. So use 1% of the material to make a web of this thickness and divide the rest of the material between the two flanges.

Totally impractical as a real-world object but fits the question very well.

A little thought on the first example given in the original post would show the form of the question presents difficulties.

You do not need to be Superman to deflect a rectangle on edge. Take a ruler and try it. Press not too hard and it will buckle out of the plane of the applied load. And that is the problem every real-world engineer has to face. Pushing on things in one way induces forces and effects in another.

A more simple example is compression. Intuitively, why would we expect a structure to behave much differently when we squash it as opposed to when we pull it apart? But it does. And this has been known since Euler's time.

So when we bend something, we have both tension and compression (and anyone who has ever cut a branch of a tree will know this) and the member subject to bending will inherit some of its behaviour from both of these.

Robert Atkinson 2.

Robert Atkinson 2.