In a recent thread on Boring Bars Steviegtr asked which was stronger, square or round section bars. Good question, that I got wrong by saying for the same weight of metal round bar is stronger than square. Duncan Webster corrects my mistake in Steve's thread.

Looking it up, I'd misremembered. I was thinking of tube versus solid rod. However none of my books have a simple comparison of the effect of cross-sectional shape on beams. Instead they all have a Chapter full of hard sums showing how to work it out. Duncan applied the maths to prove me wrong in Steve's thread: not easy.

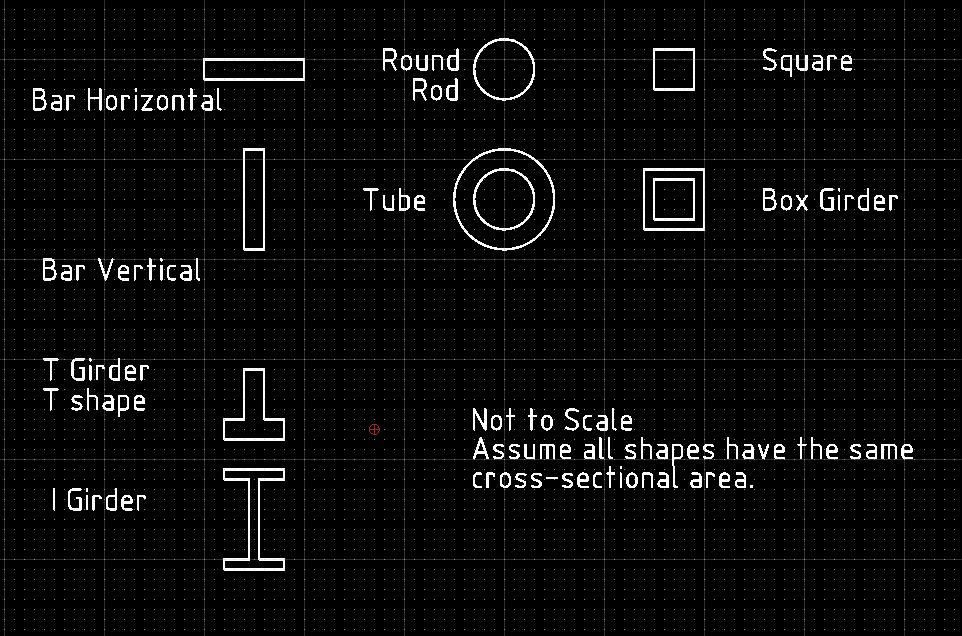

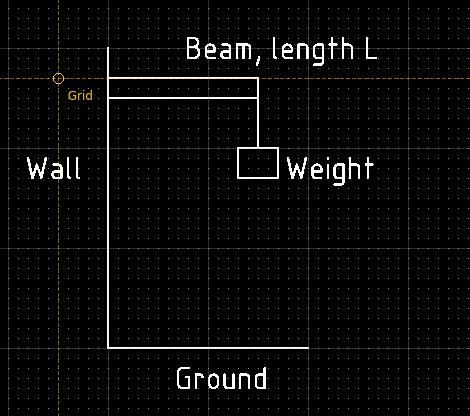

Can the team provide a simple answer to the following. Assuming the same weight of metal is used to make a beam of the same length, which shape bends least under load? ( Assume the beam is rigidly fixed to a wall at one end, and weights are added at the other.) Some examples:

Just for starters, the first two rectangles are identical except one bar is mounted horizontally, while the other is vertical. Experimentally bending a steel-rule shows immediately that the same lump of metal behaves very differently. Held horizontally, the rule bends easily – a child can do it. Held vertically, it's a job for superman. As the same shape is both strong and weak depending on load direction, the engineer has to understand and choose cross-sections appropriately.

Michael mentioned resistance to torque (twisting force) in the Boring Bar thread as being something a round section would resist better than square. I don't know, but suspect an ⌶ girder is stronger right/left and up/down than a tube, but the tube wins if the beam is twisted. Several other shapes might be useful depending on which forces a beam has to resist. How about ⌴, ⎔, △, and ☆?

Dave

Robert Atkinson 2.

Robert Atkinson 2.