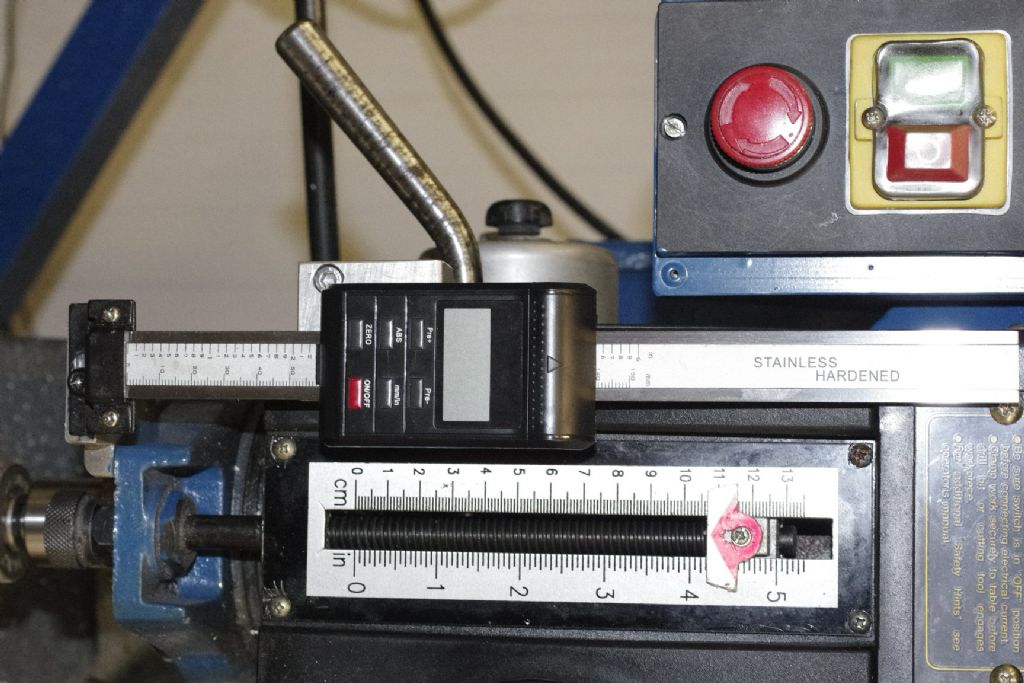

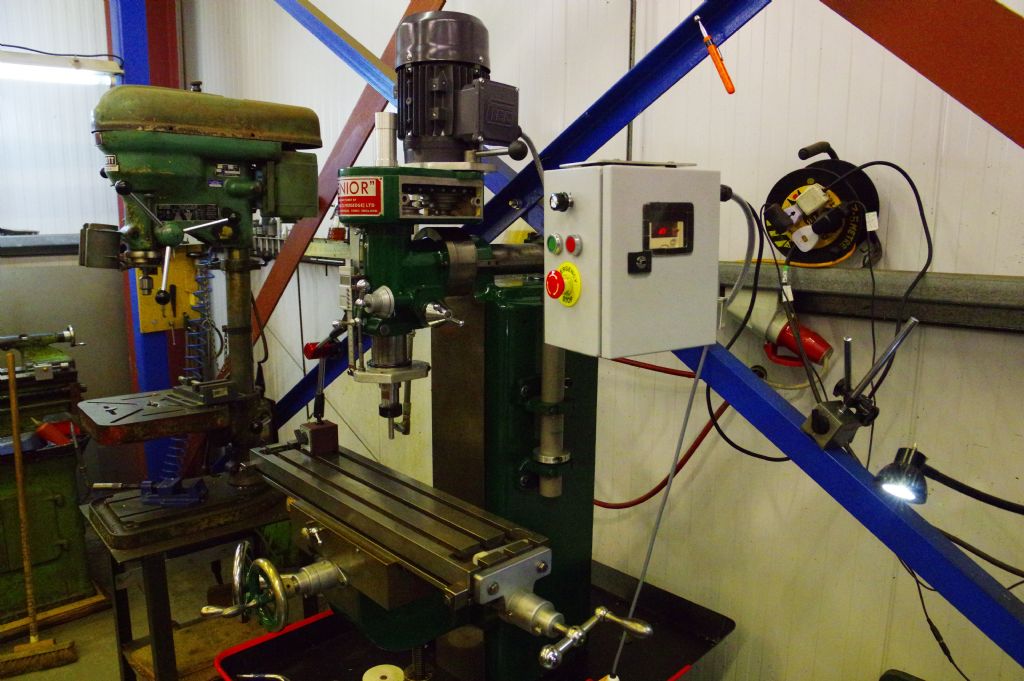

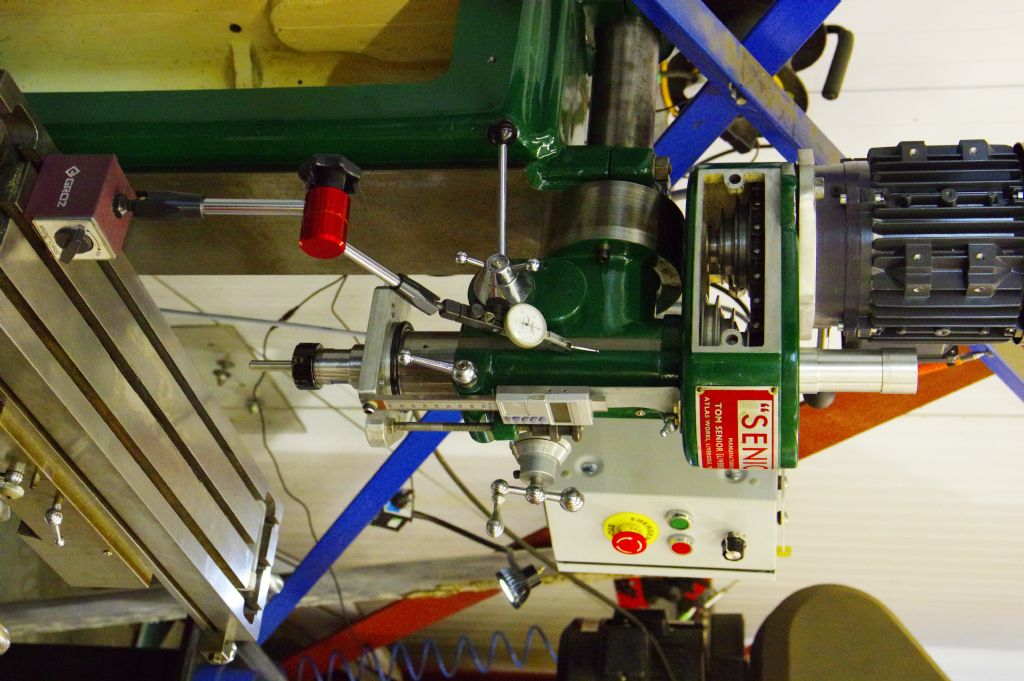

I have pretty well finished the electrics, except for making a bracket for the second emergency stop button. When I checked the wiring continuity with a meter, there was an inconsistency in the contact resistance in the regular stop button and one of the emergency stop buttons. They are in series, all the inverter controls are remote. The switches are Chinese and there is nothing obviously wrong with their functioning. Not having any Servisol switch lubricant, I gave each switch a good dowsing in AC90 which is similar to WD40. Now they work as they should, and I did the same to the start switch, just in case.

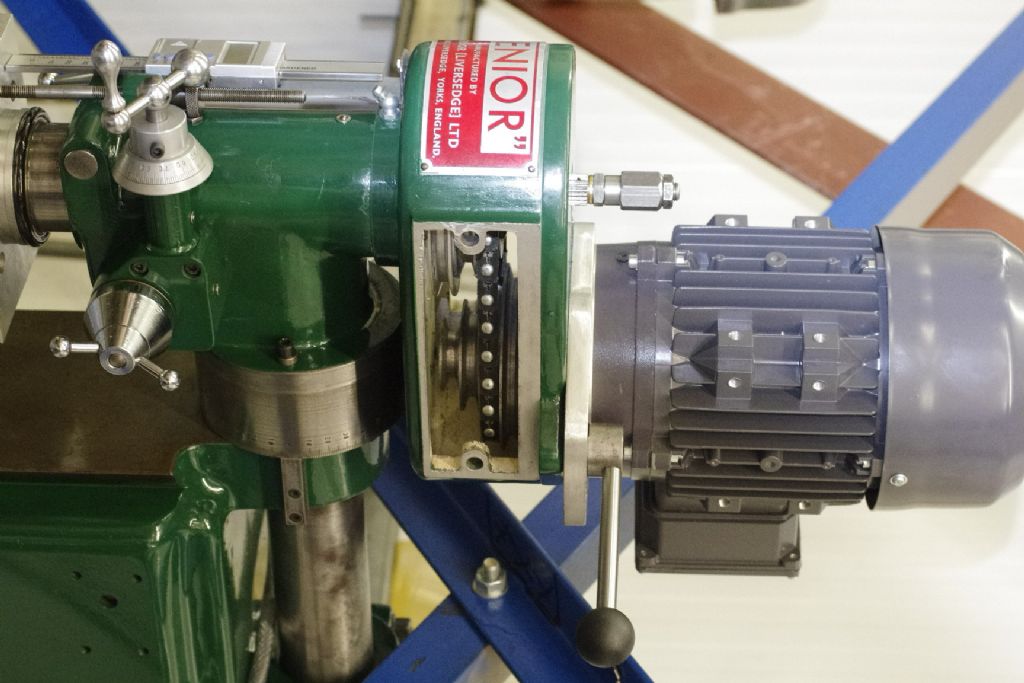

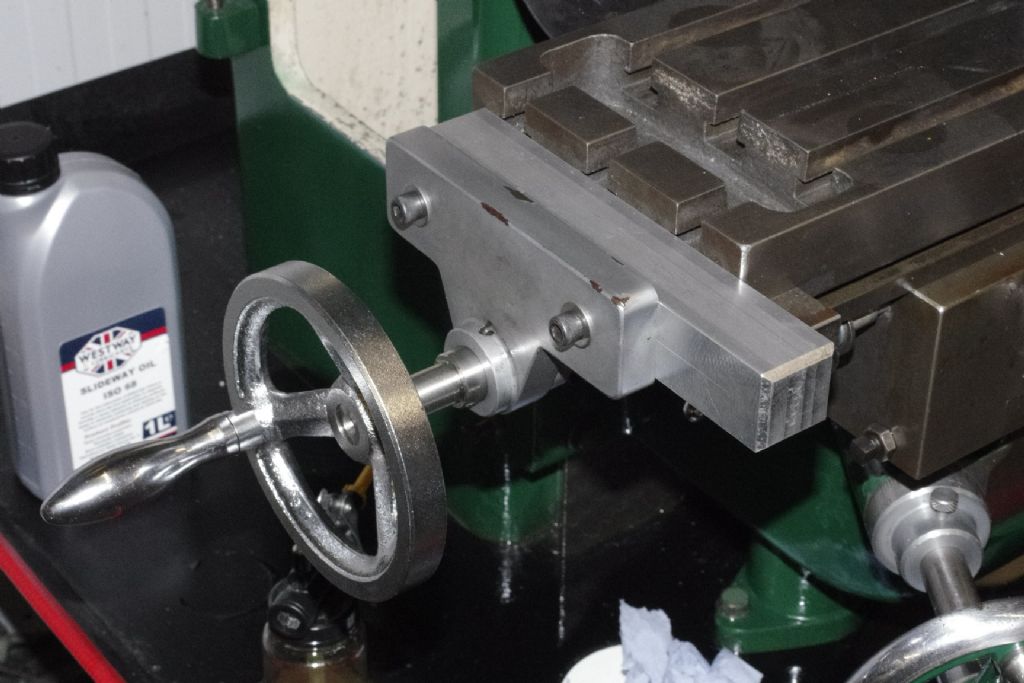

The inverter is a Schneider ATV12 0.75 Kw and the motor is a TEC three phase 0.75 KW six pole. I bought them from The Inverter Drive Supermarket and chose one of the inverters that benefited from their quick start guides pdf which Rod printed out. It took me about an hour to get the programming to my satisfaction, it would taken a year without the QSG. I have the frequencies running from 25 to 75 Hz.

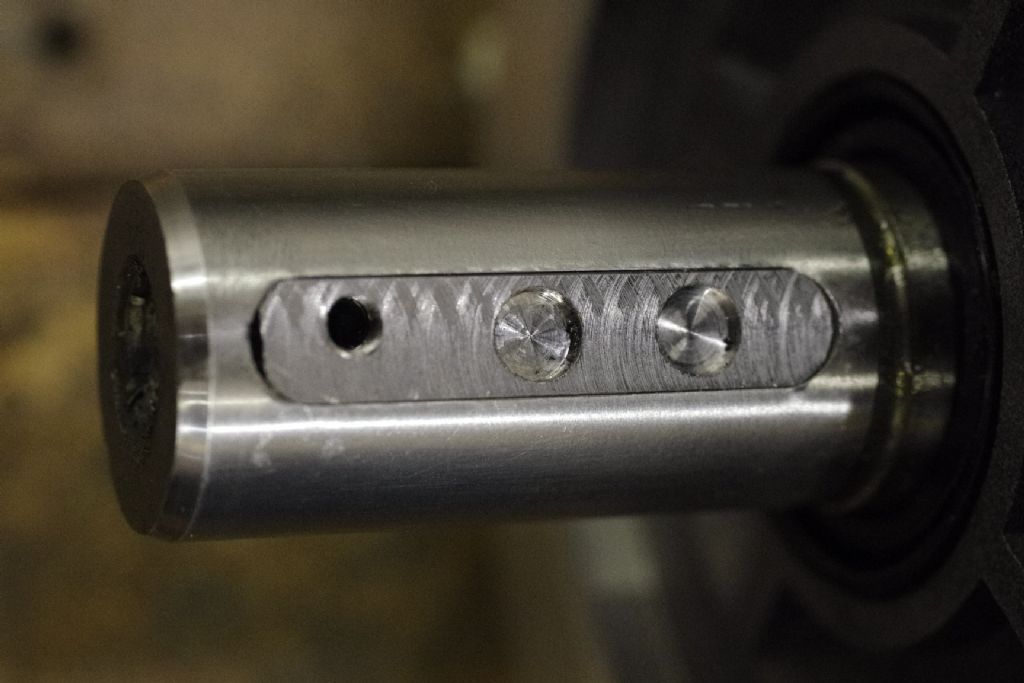

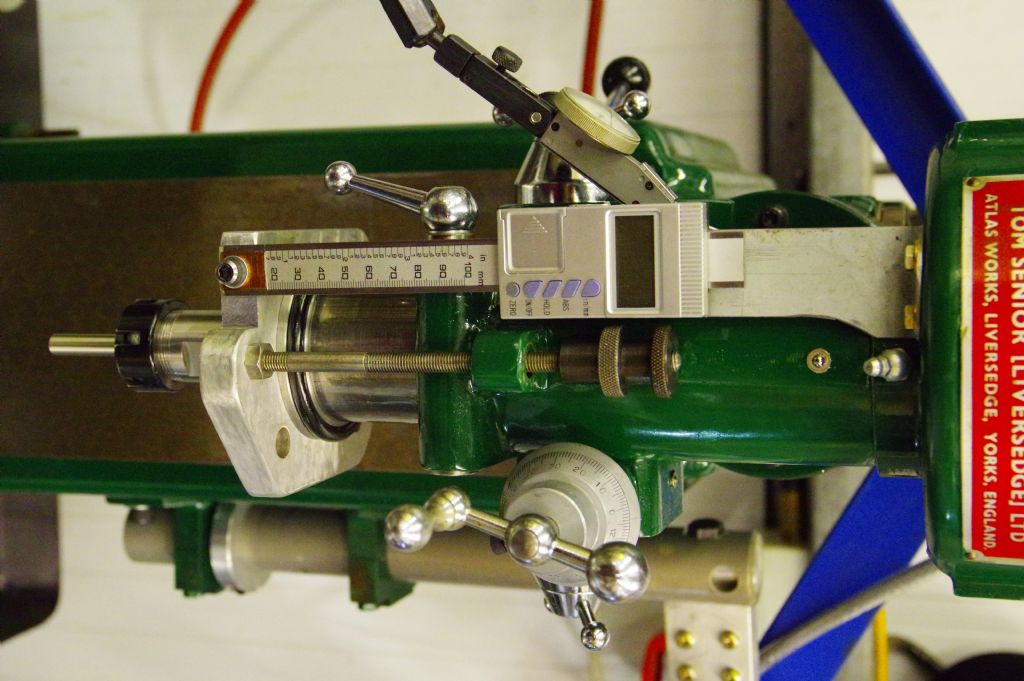

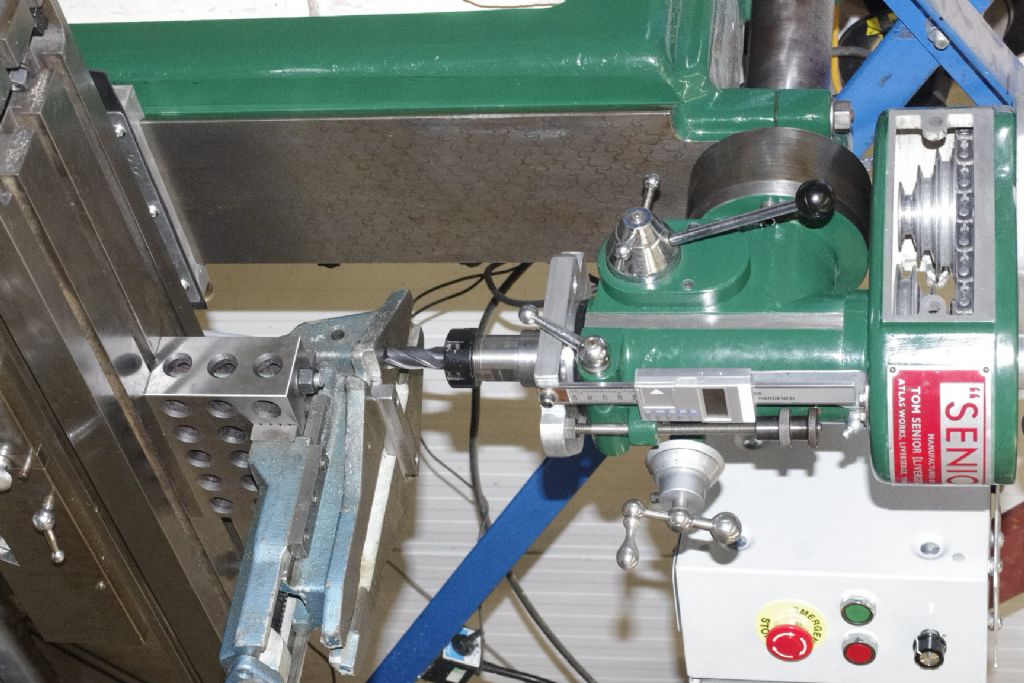

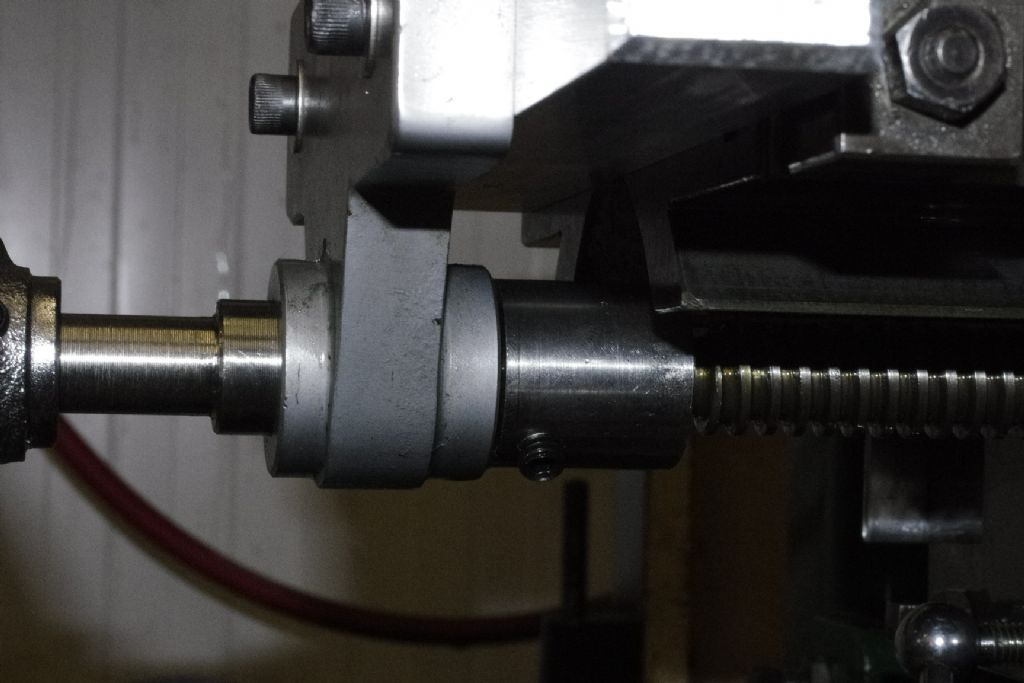

The link belt turned out to be two links too long and it rubbed the housing in top speed pulley configuration, and the spindle is overheating. It still ran hot after slight slackening, and if one more adjustment does not do the trick without over slackening the bearings, I will have to assume that I have overpacked with the grease, and will have to remove the spindle from the quill to remove some. I fitted a double lip oil seal with the same id as the spindle nose diameter without the garter spring, and bored the bearing housing where the seal sits a couple of thou oversize, so it will not be too hard to push out when or if the spindle is removed.

I will post some more pics next week.

old mart.