Richard, nice scraper. I might grind up an old screw driver or a piece of HSS to do the same job.

Latest – if anybody is interested?…..;

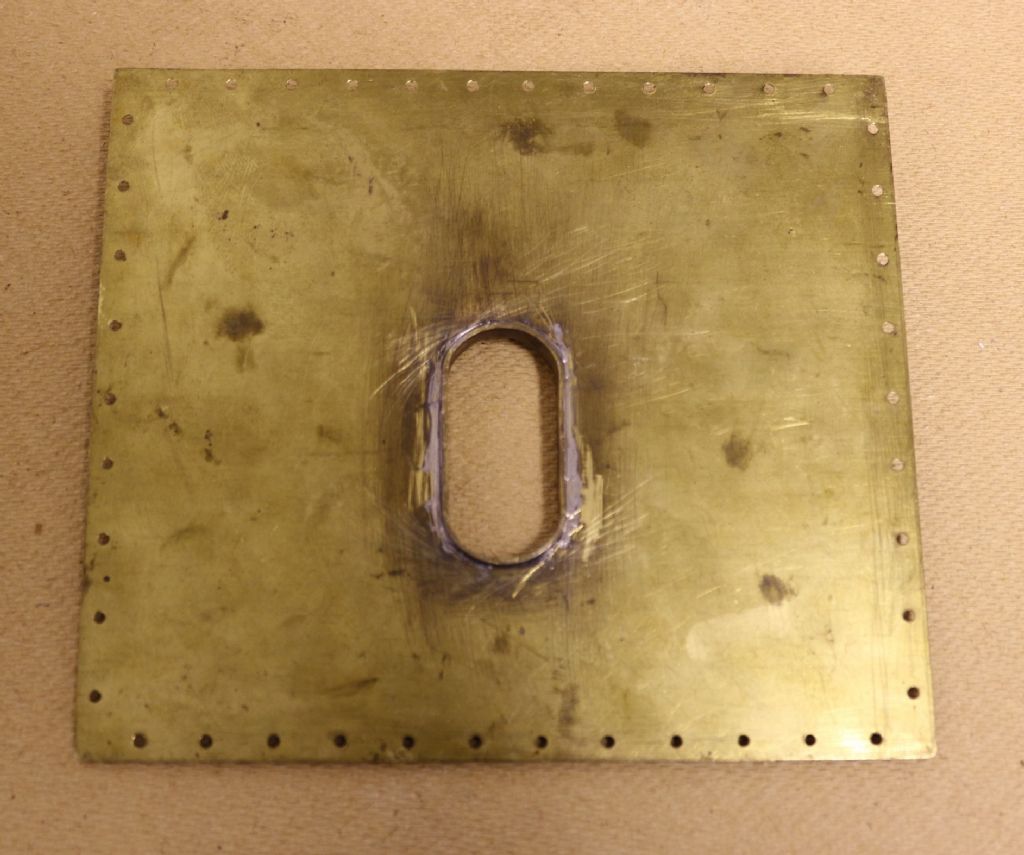

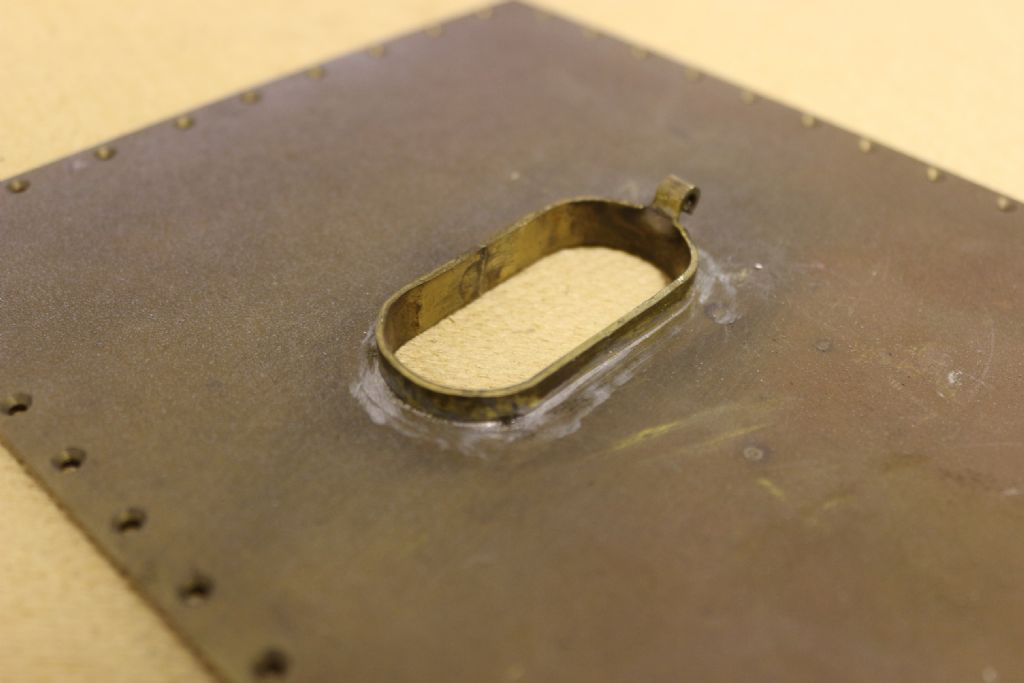

I decided to leave the access hole to the emergency pump alone. After cleaning with emery cloth etc, the existing soldered joint is quite nice so I levelled the top of the hole surround with a file and polished the plate. It now looks quite nice.

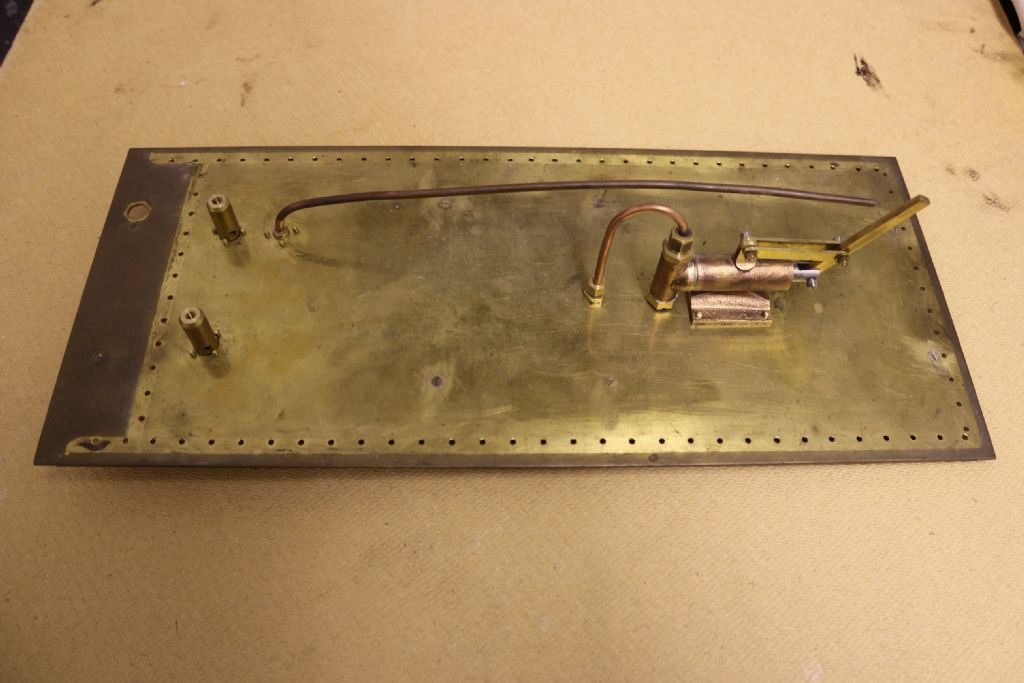

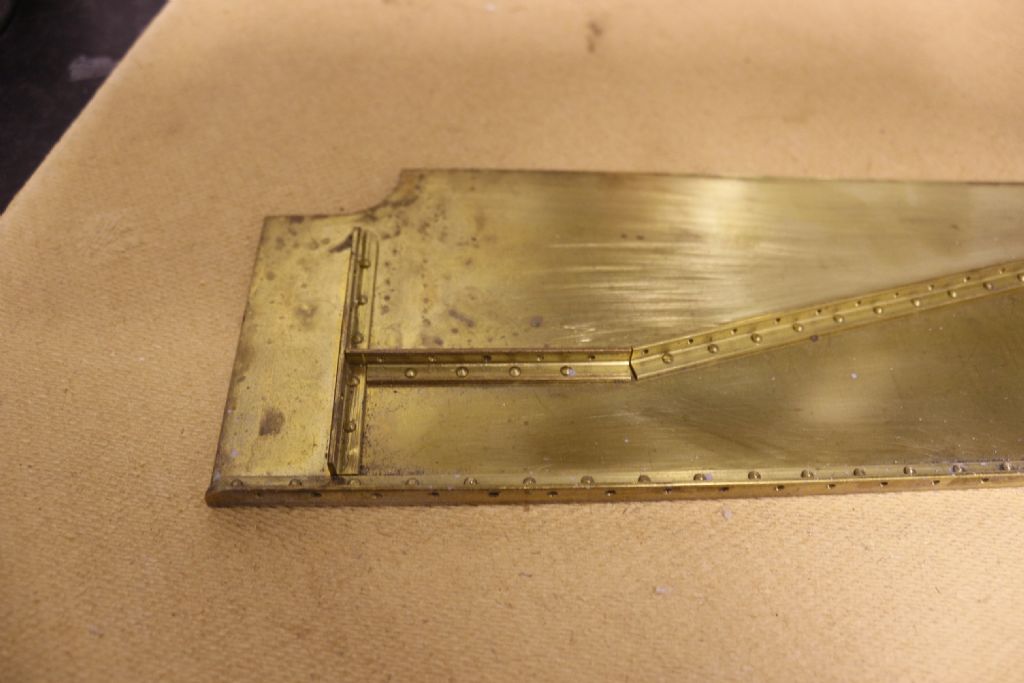

I did try some lead solder (180 degC stuff) on the front plate of the tender tank using a DIY, central heating type flame torch on a small flame. The good news is that my technique to clean the rivet heads and angle using emery and a Dremel went well because the solder formed nice fillets. The bad news is that even with very careful heating, the plate did distort significantly. Luckily, this particular plate is only about 61/2" wide X 3" and it was quite easy to straighten it back out using wood and a few taps from a mallet.

So, for my next trial, I will ditch the small torch, buy some lower temperature solder and a big soldering iron and try again. I was lucky with the front plate. If I distort the tender sides, I doubt if I will be able to retrieve them.

Phil H

Buffer.