Posted by Madhatter on 11/06/2018 16:48:05:

I was merely going by what the agents advertise the unit as, like Michael G said "

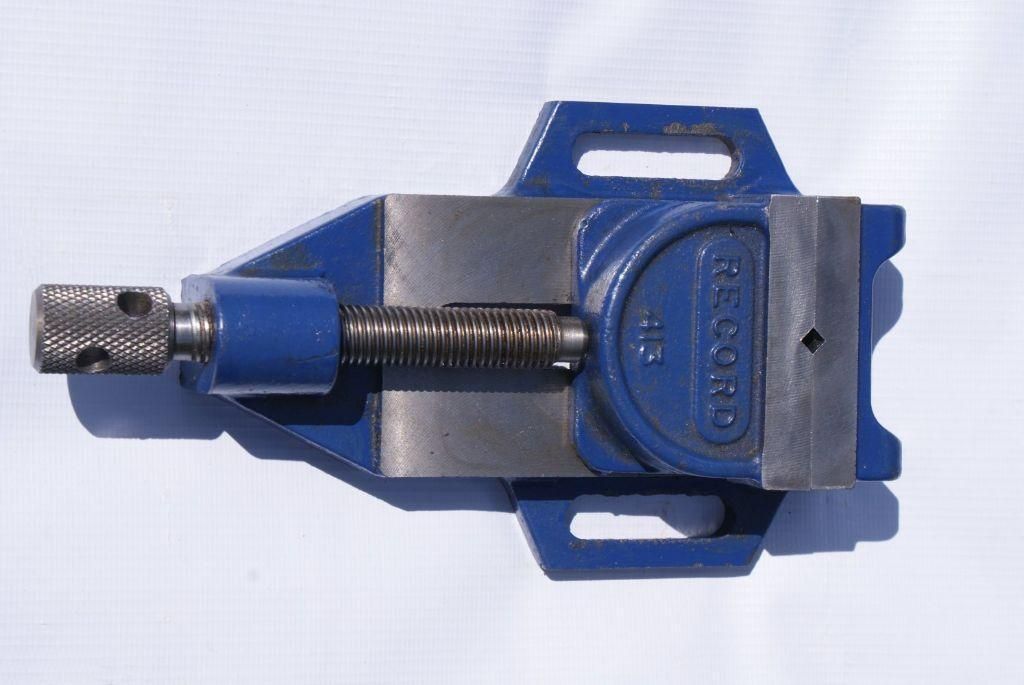

What constitutes 'precision' in a general purpose drill vice ?

… or, in this context, is the word just worthless advertising puff ?"

Given half an excuse I blather on endlessly about NOT taking words like 'precision' seriously UNLESS it's explained what it means AND you can measure it.

The view isn't prejudice, it comes from professional purchasing. At work when a chap asked me to buy him 'a quality do-dah', he was told to think again. Not because he didn't deserve a do-dah, but because he failed to justify what he needs in the way of 'quality'. I insisted on knowing exactly what was needed, why it was needed, how long it was needed, and what the cost-benefit was. No way would he be rewarded for laziness, or wanting a tool conferring bragging rights, or wanting to waste money on an expensive tool that only got used once. Over-specifying is a grievous sin because it wastes money better spent elsewhere.

Far more useful to define what you mean by 'Value for Money' and 'Fitness for Purpose'. In this case, when buying the vice, you assumed the jaws remain parallel because the word 'precision' was mentioned. Actually, precision in a drill vice probably refers to the flatness of the working faces, not to jaw parallelism. If the latter matters, you need a different type of vice.

Defining 'Value for Money' and 'Fitness for Purpose' doesn't mean 'buy cheap'. Quite the opposite. Like as not proper analysis will tell you to buy the very best you can afford. Hobbyists are a little different because they pay their own bills. My budget and requirements mostly point me at inexpensive tooling. Your budget and requirements might well be the complete opposite. We're both right! I even respect 'Tool Tarts' because to me they're just another facet of an interesting hobby: if someone enjoys buying expensive brand-name gear and polishing it, well done!

Apologies if I sound unsympathetic, it's just my pedantic Asperger's streak likes engineering text to be precise with precision, quality, and other blurred words. It's very sad because I often fail to be clear myself…

Dave

Edited By SillyOldDuffer on 11/06/2018 17:58:37

Mike Poole.

Mike Poole.