Posted by peak4 on 05/01/2019 18:54:14:

Posted by Daniel Grant on 04/01/2019 21:52:21:

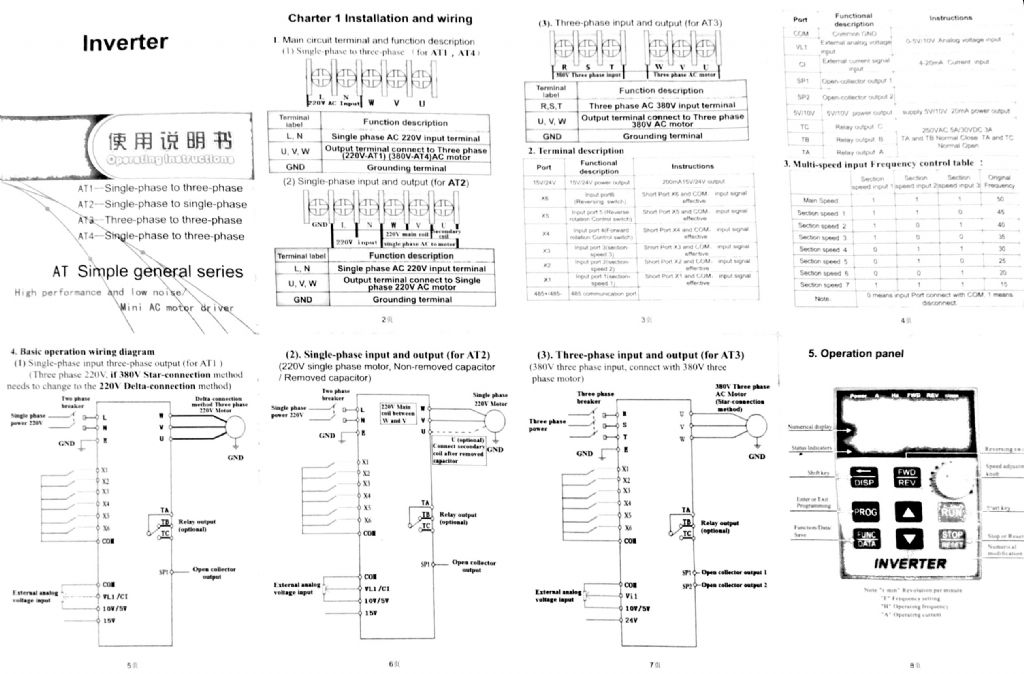

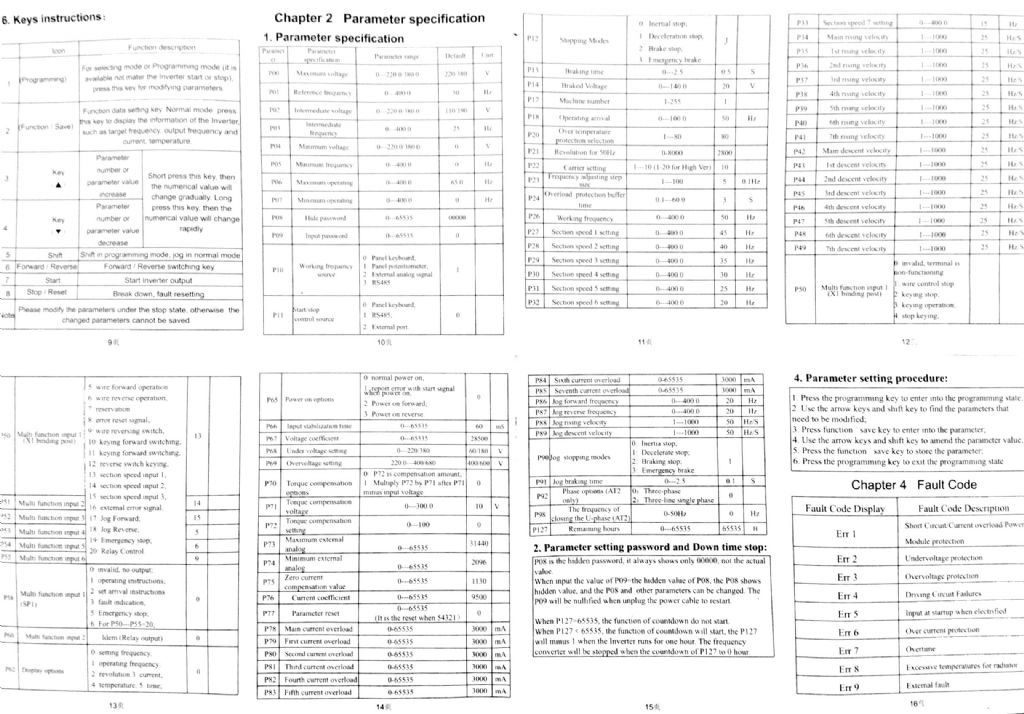

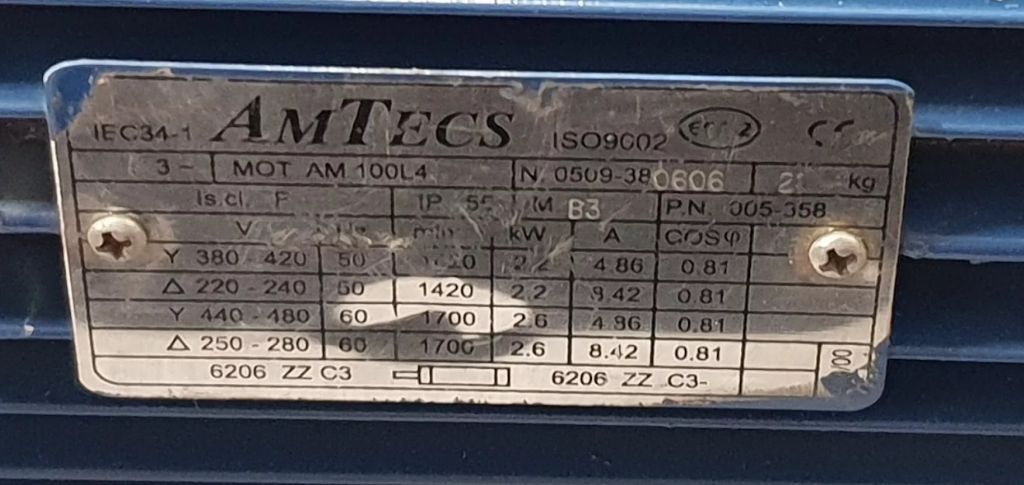

The model is an AT4, but the motor has to be converted to 220v to run. Well spotted on the 3000ma max current Dave, that could well be what’s tripping it. I’ll try changing it tomorrow.

Struggling to get the images uploaded after using camscanner, I’ll try to get some clearer pictures.

Well as I read it, on Page 2 of your "manual", assuming your converter really is an AT4. and not a mislabelled AT1, then the motor should be wired 380-420 in star config, not 220-240 delta.

As mentioned above, try it on the other motor, also wired as 420v star and see how it works with that.

The motor sounds very much like one of mine did when I connected it to a dodgy inverter, where one phase was faulty. Measuring the output voltage with a meter was misleading, as it showed about the same voltage on each of the phases; mine was running in delta with a 240v motor.

It was only when I put the oscilloscope across the terminals that it became obvious that I was a phase down.

Bill

Edited By peak4 on 05/01/2019 18:56:27

My reading is that the AT4 is like an AT1 except it produces 380V out.

I wonder if connecting a high voltage VFD to a 220V motor would produce the symptoms?

Hypothesis.

Being a box full of electronics with a brain the size of a planet, I don't think a VFD would behave anything like a real three phase supply. Connecting 380V from the national grid into a 220V motor would be obviously wrong – smoke and blown fuses make the fault easy to diagnose! I think a VFD is more subtle.

The VFD generates 380V 3-phase electronically and applies it to the motor. It's power output is limited by the electronics. Everything it does is measured and managed relative to the configuration settings, which include soft safety features intended to protect the electronics.

When a 380V output VFD is connected to a 220V motor the VFD will immediately detect that it's drawing too much current but it keeps going for a short-time because the excess might be normal starting overload. However, if the motor carries on drawing excessive current, the VFD shuts down. That seems to fit the symptoms.

I'm not at all sure how a 220V 3-phase motor would behave when fed excessive volts that are also current limited at source, varying in frequency and – perhaps – trying to follow a software defined starting routine. It seems possible that the motor would run badly for a short time before the VFD decides to cut out.

Daniel : why do you think your AT4 isn't producing 380V 3-phasel? I think the star-delta comment in the manual that implies that refers to the AT1 not the AT4. I agree with Bill – as he said, "try it on the other motor, also wired as 420v star and see how it works with that."

Motor experts: I'm out of my depth and there are safety implications, but is there any reason why a VFD couldn't be tested by wiring 100W filament light-bulbs in star or delta and using them as the load? If the bulbs glow equally, all three phases are working. I'd expect a 220V VFD to light a set of 3 bulbs fully once power is cranked up, and a 380V VFD to burn them very bright. (Wiring this up at 220V is dangerous, 380V more so.)

Dave

Emgee.