Posted by Ketan Swali on 04/04/2021 10:55:50:

Hi Joseph,

Surprised to see an EMCO aficionado ask a question about an SC4 headstock. I must be dreaming

Hi Ketan!

Thanks for responding, and your opening line did make me laugh! However you probably realise behind my questions lurks an agenda…

What I am trying to do is mechanically unsound, frowned upon and will get me shot on this forum..

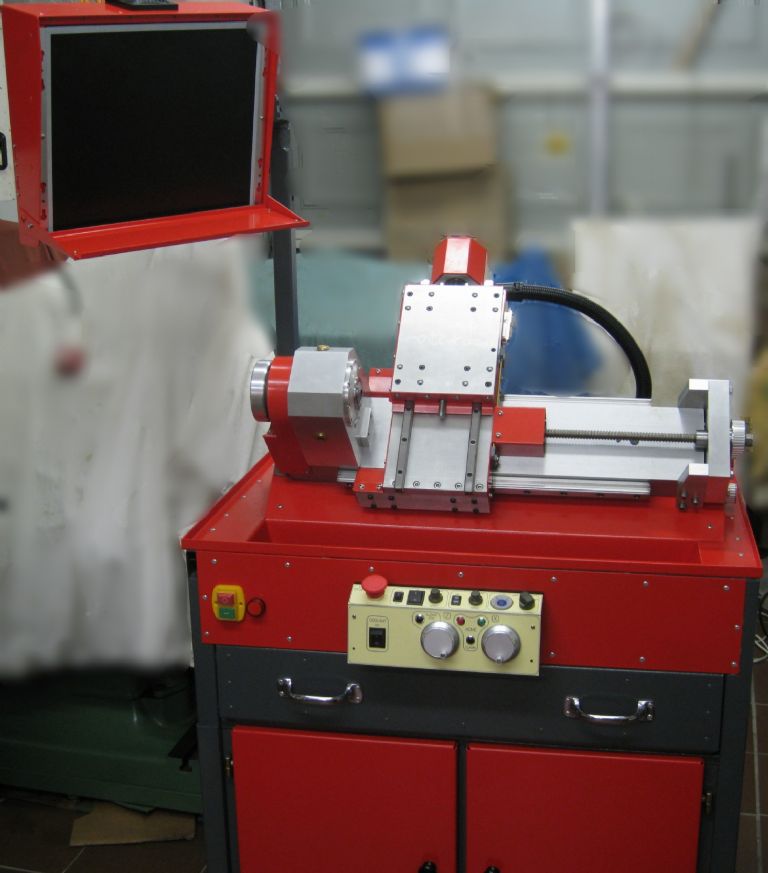

You may have seen my 'little' CNC lathe project – well, it has taxed all my abilities, including the brain muscle, which has been found wanting…

As with everything I do here, the solutions are very much driven by what I can obtain, and what is 'importable' within practical limits!

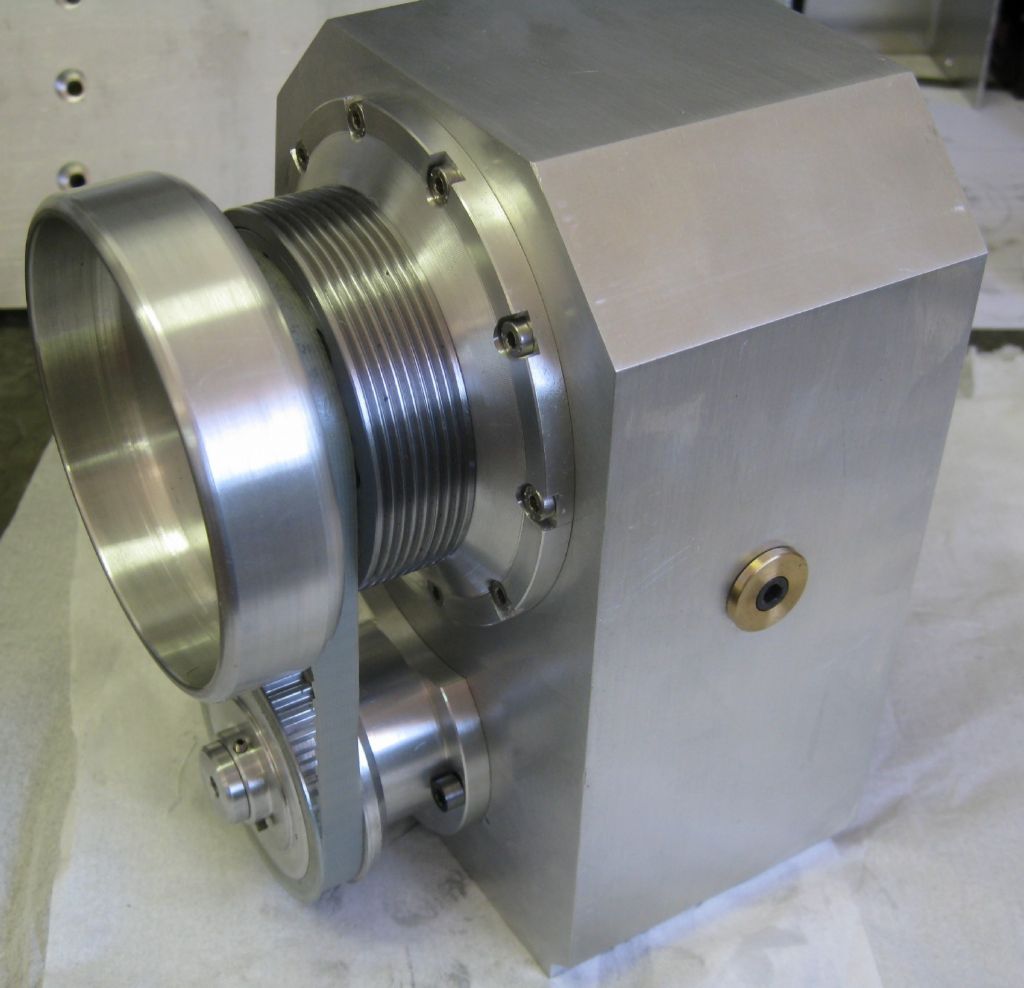

So, the headstock/spindle on this project became a 5C collet setup, with the spindle length dictated by available suitable steel – which ended up being from a section of sheared caterpillar drive shaft…Likewise , the headstock popped out of a chunk of Ali that followed me over the years – no such size material available here! Suppose I could have used a chunk of cast iron from the caterpillar engine..

The collet closer is a 120mm diameter handwheel. There is no space for a tommy bar/spanner hole/flat in the spindle nose or rear to hold the spindle whilst fastening the collet with the handwheel. The spindle motor – a 2KW closed loop brushless servo – has a holding torque of around 40NM, so was banking on that holding the spindle while tightening the collet. It works fine..but the manual effort required on the handwheel is too much. I can replace the handwheel with a torque nut, etc, but there are just too many issues that are now turning into a hack..

So, I want to remake the spindle, to take a 5C collet chuck ( a Bison unit) – that works like a normal 3 jaw chuck –

The chuck is 125mm OD, and 110mm to the collet nose from chuck back. The chuck main body is 125mm OD x 70mm thick. Add the backplate and its space to the headstock and the chuck nose is maybe 125mm from the end of the bearing..

My headstock is only 100mm wide…the bearings used are 100mm OD, 50mm ID, taper rollers, which are also an issue – Headstock is oil filled, but is dribbles from the labyrinth seals, and I have battled enough now! So I want to fit 100MM OD, 50MM ID, 30degree sealed, grease filled Angular Contact bearings instead, with a good preload.

Intended max RPM is 4000 for short periods, but mostly sub 2000RPM.

So, a 125mm OD 5.6kg chuck, 25mm longer than the end to end spacing of the (LARGE) spindle bearings, spinning at 4000RPM….not big loads in the machining, as the stock is limited to what 5C collets can take.

I looked at all the links you provided – I looked also at the Little Machine Shop USA site – they have a dimensioned drawing of a C3 headstock – indicates 106mm bearing outer spacing. Don't think a C3 will take a 125mm chuck..

Now to get into my bomb shelter…

Joe

5C chuck…

The current headstock bits

Lower bit is the spindle encoder

Joseph Noci 1.