I give up.

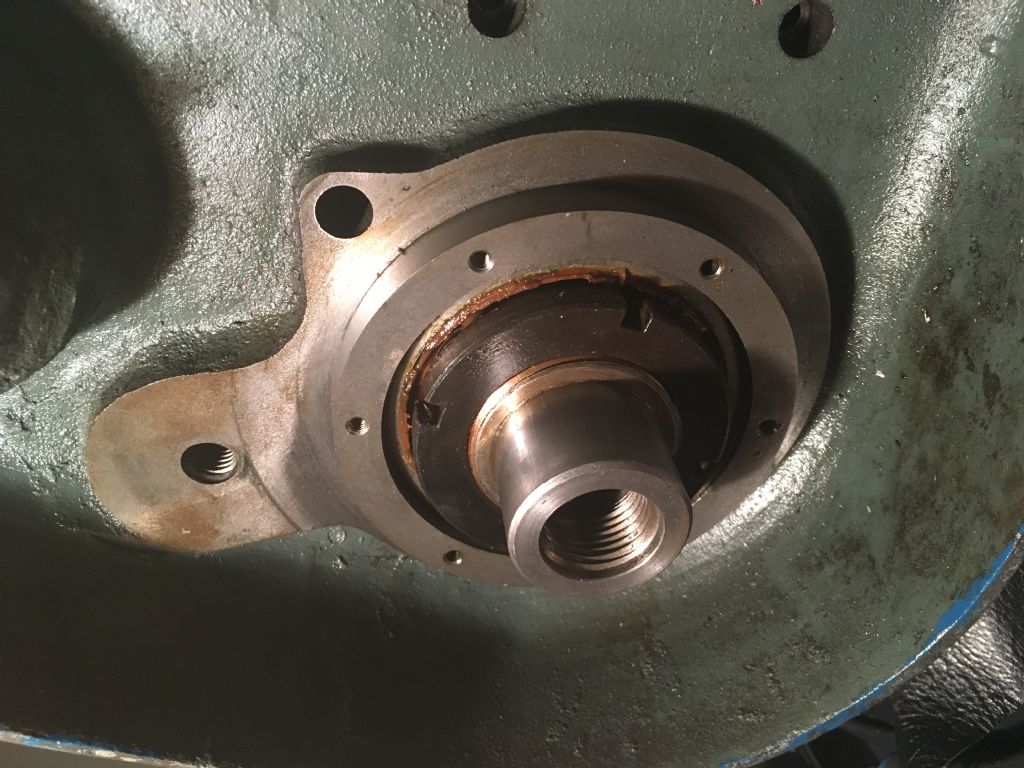

I've tried getting this gear box off for something like two weeks now. I've taken every screw I can see out of it and it won't budge. The whole gear box is a layer cake with four parts. I've gotten the front end off, which holds the feed rod for the apron. What is left is the rear cover for the changewheels and the tumbler mechanism in a separate housing behind it. I've take pictures from inside the the rear foot of the bed and can see at least one threaded hole there which I assume holds a screw that I haven't undone. To get at it I need to get the change wheel cover off. I've removed everything fastener I can see except for the large flange nut pictured. It holds the large bearing for the leadscrew (this lathe has dual feeds). I find it strange because in the rest of the lathe the bearings will come out of their housings rather easily axially. Then again, this is a bearing that will see a fair amount of axial load being a lead screw bearing. So you'd want to keep it very closely aligned axially.

The casting flexes a little bit when I apply pressure at the top and reveals the separation between the parts. It does not at the bottom. Almost all of the parts have been painted over so it's hard to tell if that's why the parts are stuck together of if there are som fasteners I've missed left in there. The only thing I can SEE though is this nut and I think it may be compressing the other parts.

This became a long winded buildup to my question, just wanted you to know what I've tried so far and how the problem looks at the moment.

How do I get this nut off? This is the largest of its kind on this lathe. I have a single pronged spanner that I've used on the others and the best way to use it has been to use it to lock the nut and then turn the screw. I can't get a grip on this without damaging I'm afraid. I've used one of the change wheels for leverage but then getting the spanner in behind it becomes a problem. Plus I need to hold the change wheel by hand as not to damage it. I've put some penetrating oil on it now and I'll revisit it in a day or two.

I know this is an unusual lathe but if anyone has any specific advice on this lathe I'd love to hear it. Or if someone can point me to an authority on Habegger lathes. This is a Habegger DLZTE.

I'll also take any advice I can get in regards to removing nuts such as these.

The reason I want to get the gear box off is to be able to better handle the lathe bed for paint stripping and painting witout risking damaging the gear box castings.

Best regards

Karl

Hopper.