Hello all.

I was recently trying to get hold of some LG2 (or Colphos 90) but in plate form. It soon became clear that these materials are more widely available in hex or bar and that I'd find it nigh on impossible to buy as plate.

My question is, if I absolutely needed LG2 in plate, how feasible would it be to get a foundry to melt a bunch of ingots and re-cast 'em into plate? Would it dramatically change the free-cutting/weather-resistant properties? Would it end up looking like the inside of an Aero bar?

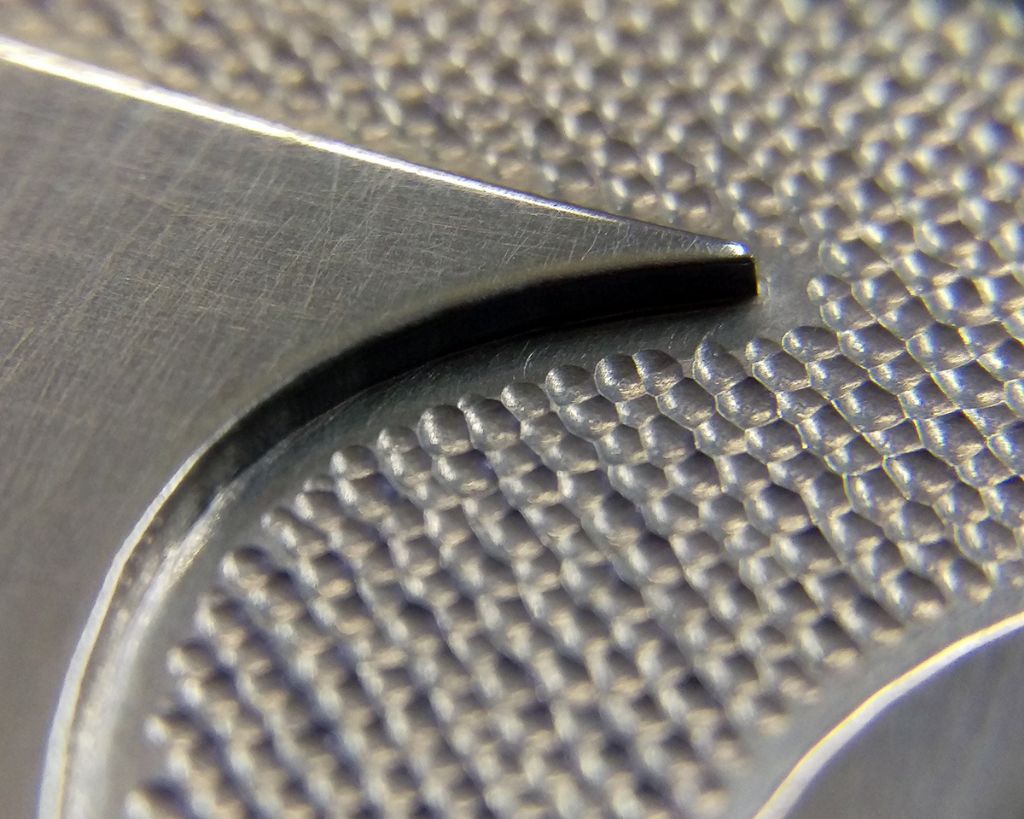

This is just an idle question from someone who doesn't know all that much – I'll likely go with Naval Brass (CZ112) – not as aesthetically pleasing, but available in plate and meets the hard wearing / good in a marine environment requirements. Not as free cutting, but should be OK – there are a lot of letterforms which will need to be machined using end-mills down to 0.5mm, as in the pic.

Many thanks for your advice, excogitation etc.

Wal.

JasonB.

JasonB.