Don't it always seem the same, you don't know what you've got 'til it's gone… as the song goes.

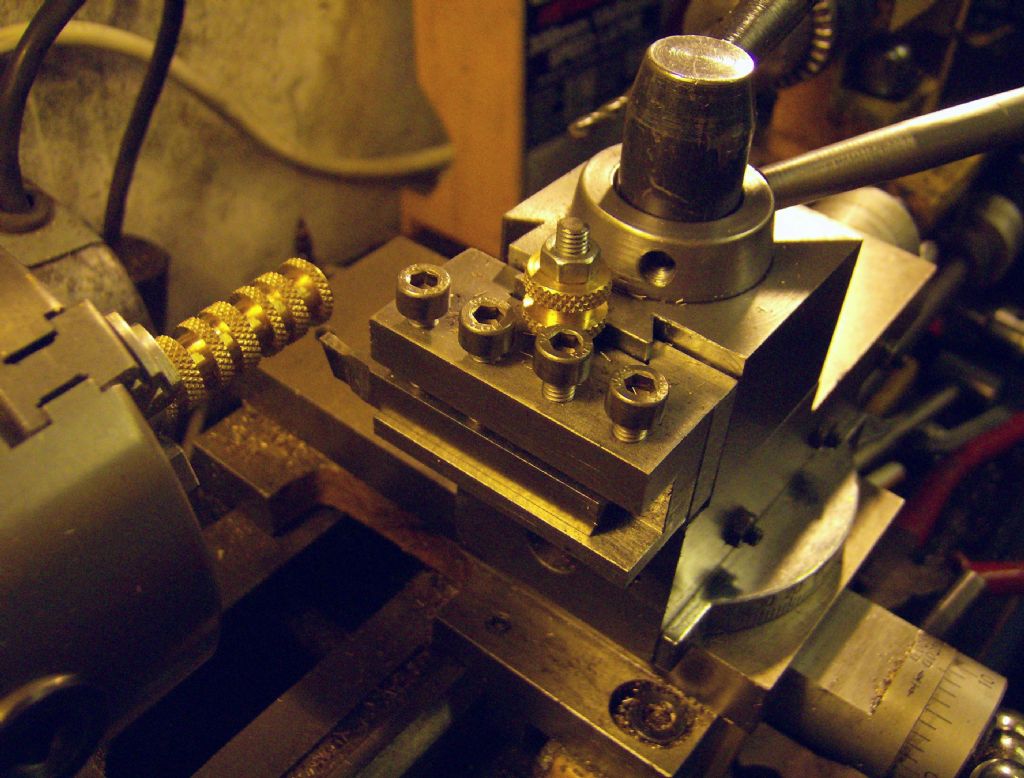

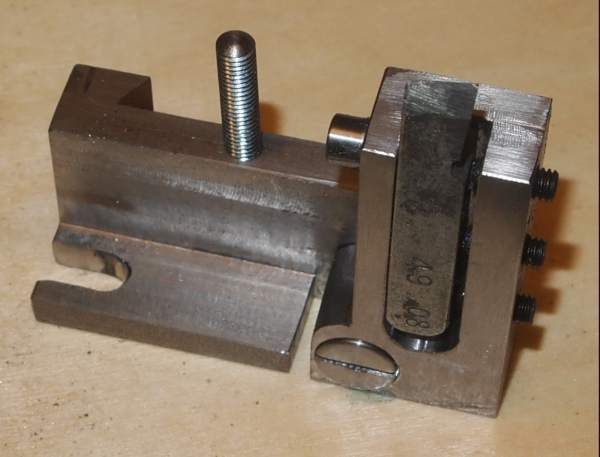

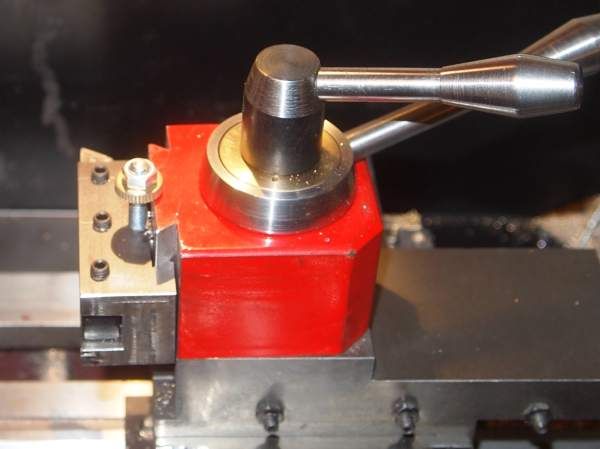

I got a pile of eight more toolholder blanks, milled out rectangular recesses for the dovetails (would have been a nightmare without my stiffening plate), then put one in the clamping opiece of my knurling tool. and pleased to see the endmill still looked like new at the end.

Got the dovetail cutter out, and finished the dovetail in the knurler and six of the blanks, then almost at the end of the seventh blank, the bloody nylon gear inside the X2 mill went

I've opened it up and it looks like the gear exploded! I can find most of the 20 tooth gear that wasn't engaged, but of the 12-tooth end that was, all I can find are about half of the teeth. They must have completely stripped, before the rest of the gear shattered.

My calculation is that it is 2.25mod, but without atwo teeth side by side to check the cutter against and the thought of having to botch it up on the lathe, I think I might run up the white flag and order a metal replacement on payday.

Had to happen sooner or later – but it's interesting how short the time was once I had the mill rigid enough to start cutting close to its capacity.

Neil

Sub Mandrel.