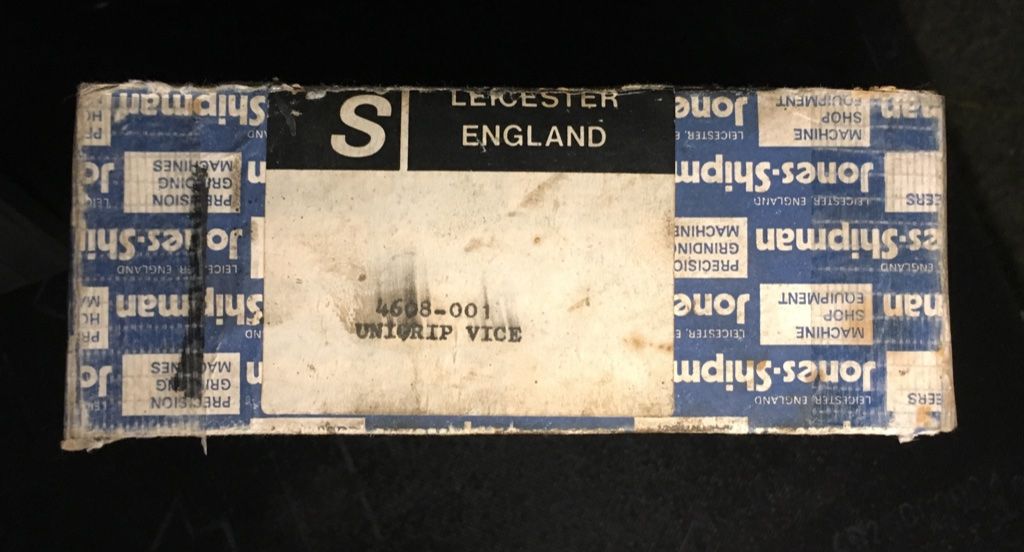

There have been a couple of threads about the NiPPY vice in recent years, one including a reference to the Jones & Shipman version which seems to have been called the Unigrip, possibly a misnomer as the elaborate jaws of both versions permitted gripping the work in a variety of ways.

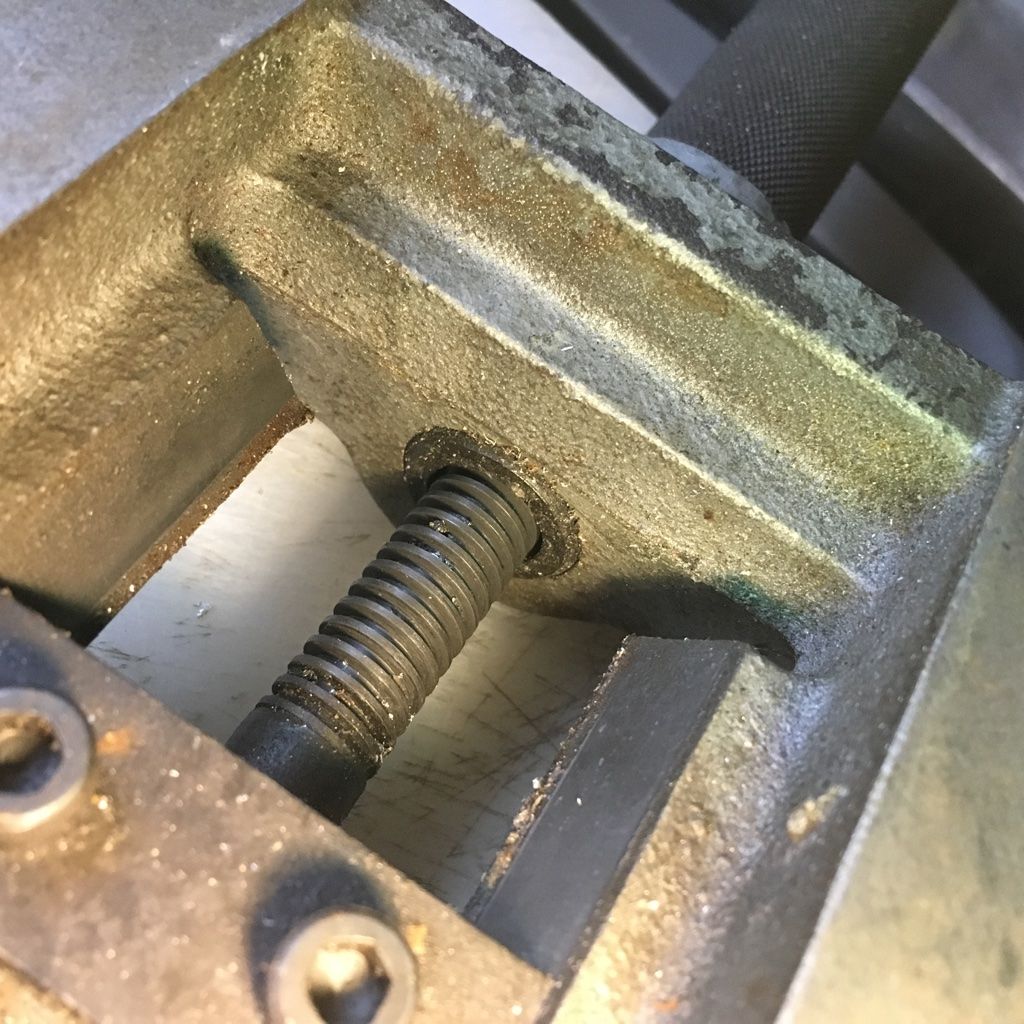

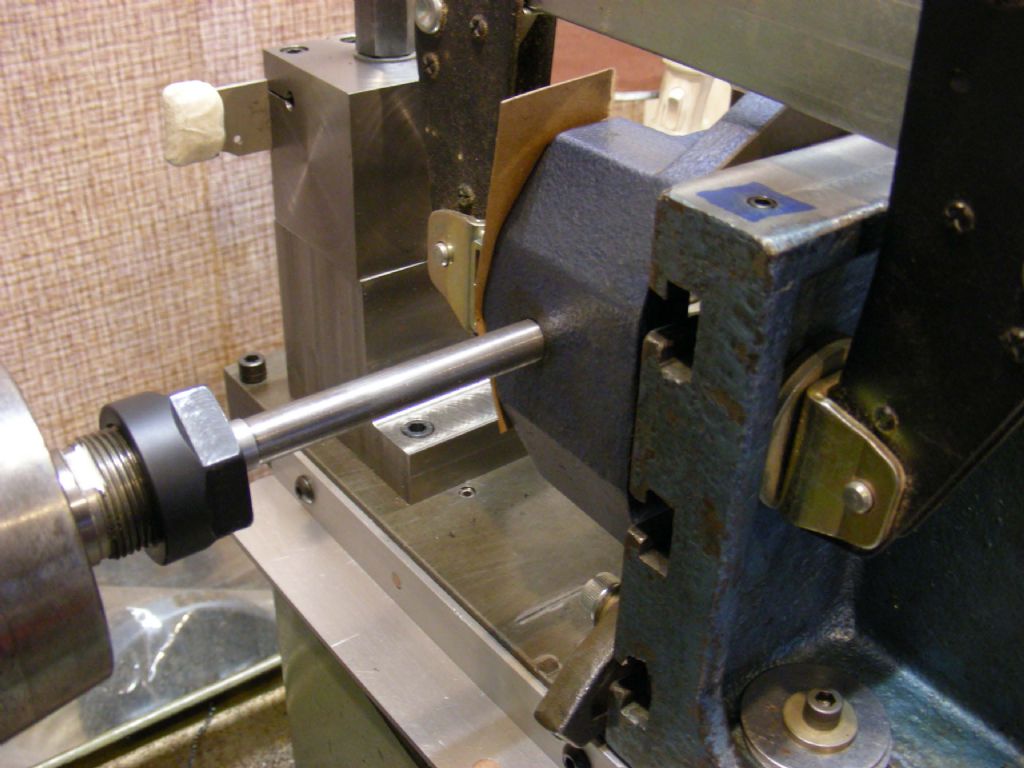

At a MEX some years ago I bought a simplified version of the Unigrip with plain jaws and RH M12 leadscrew working in a tapped hole in the casting. I have used this rather infrequently as the relatively fine screw makes adjustment painfully slow compared with the NiPPY arrangement of a LH 8TPI acme screw working in a threaded hole in the knurled handle. Having looked at a friend’s NiPPY I am planning to modify my vice to provide similar more convenient working.

The NiPPY’s clamping force is reacted via a keep plate rather after the fashion of the ML7 tailstock and there is a spring washer between the inner end of the handle and the bottom of the hole in the casting. According to my 1976 J&S catalogue, however, their type 4608-001 version’s handle was “mounted on ball bearings to give more gripping power, smooth action and longer life.“

I speculate that this may be a reference to a thrust bearing in the same location as the NiPPY’s spring washer and, presumably, that the keep plate is still necessary. Can anyone who has the ball bearing version comment, please?

Michael Gilligan.

Michael Gilligan.