Quality issues with a SIEG SX2.7 mini mill

Quality issues with a SIEG SX2.7 mini mill

Home › Forums › Manual machine tools › Quality issues with a SIEG SX2.7 mini mill

- This topic has 70 replies, 25 voices, and was last updated 22 February 2019 at 11:33 by

Neil Wyatt.

Neil Wyatt.

-

AuthorPosts

-

19 February 2019 at 18:06 #397032

Samsaranda

Participant@samsarandaA lot of discussion has happened on this thread and cold water has been poured on the premise that temperature would not be an issue with manufacture/assembly of our hobby machines. Those who have had careers working in engineering will have undoubtedly come across thermal issues when producing parts, if certain close tolerance parts are made on a cold day and parts assembled with it are completed on a hot day then you can very easily have a conflict with tolerances, I speak with experience on manufacturing components and assemblies with sometimes challenging tolerances. In respect of castings they are nowadays machined mostly when green I.e. straight from the foundry, no weathering or time to stress relieve, this can cause a lot of problems after the component has been machined and is removed from the production fixture; in one factory that I worked in we had problems with cast iron gearbox casings moving after they were finish machined, we found that they were twisting as the internal stresses relieved themselves, the amount of movement was significant enough to cause misalignment of assembly dowel positions. We investigated it thoroughly and decided that we needed to alter the casting patterns to thicken certain areas to strengthen the overall casting, when we machined the modified castings there was imperceptible movement which in our case was acceptable. Stress relieving after machining is not confined to cast iron, it happens with the grades of carbon steel and stainless grades as well, in fact some of the more exotic grades of stainless alloys can be very challenging. Our hobby machines are built to a price and we usually purchase the best that we can afford, they are not going to perform to the standards of toolroom machines, they use castings which are dictated by price and are in comparison to heavy machine tools are relatively flexible as has been demonstrated in this post by the movement detected when bolting on a wooden base and a steel base, I would be surprised if they didn’t show any movement when the castings used are by definition adequate but viewed as unstable when compared to heavy machinery . I am not denigrating the manufacture or standards employed in building hobby machines, they are what they are, built to a price to perform a reasonably accurate function. Machines that perform precision machining processes are available but they are way out of reach of any hobby machinist, if by taking the mill or lathe apart we can improve upon the tolerances then this is a way forward for those who have the expertise to fettle or modify just as the assembly fitters used to do in our manufacturing industries but nowadays parts made in the western world are made on machines that produce to very close tolerances so only minimal work is needed upon assembly, gone are the large fitting shops where, dare I say it, sometimes items were butchered so they would fit. I own a Champion V20 mill and a Warco BV20 lathe, I accept that they are not perfect but live with their inadequacies, the mill has dro’s fitted and that makes life much easier , couldn’t do without them, the lathe is in line for fitting dro’s, just researching to find suitable candidates. I think we should all remember that our hobby machines, usually Chinese, are built to a price that we can afford and without these machines being on the market many of us would struggle to take part in model engineering.

Dave W

19 February 2019 at 19:19 #397043 Neil WyattModerator@neilwyattPosted by Piotr Gertz on 19/02/2019 14:09:52:

Neil WyattModerator@neilwyattPosted by Piotr Gertz on 19/02/2019 14:09:52:Yes it was your videos Jason, but there was more than just that. I agree I could continue using it on smaller items and never notice any difference in my results.

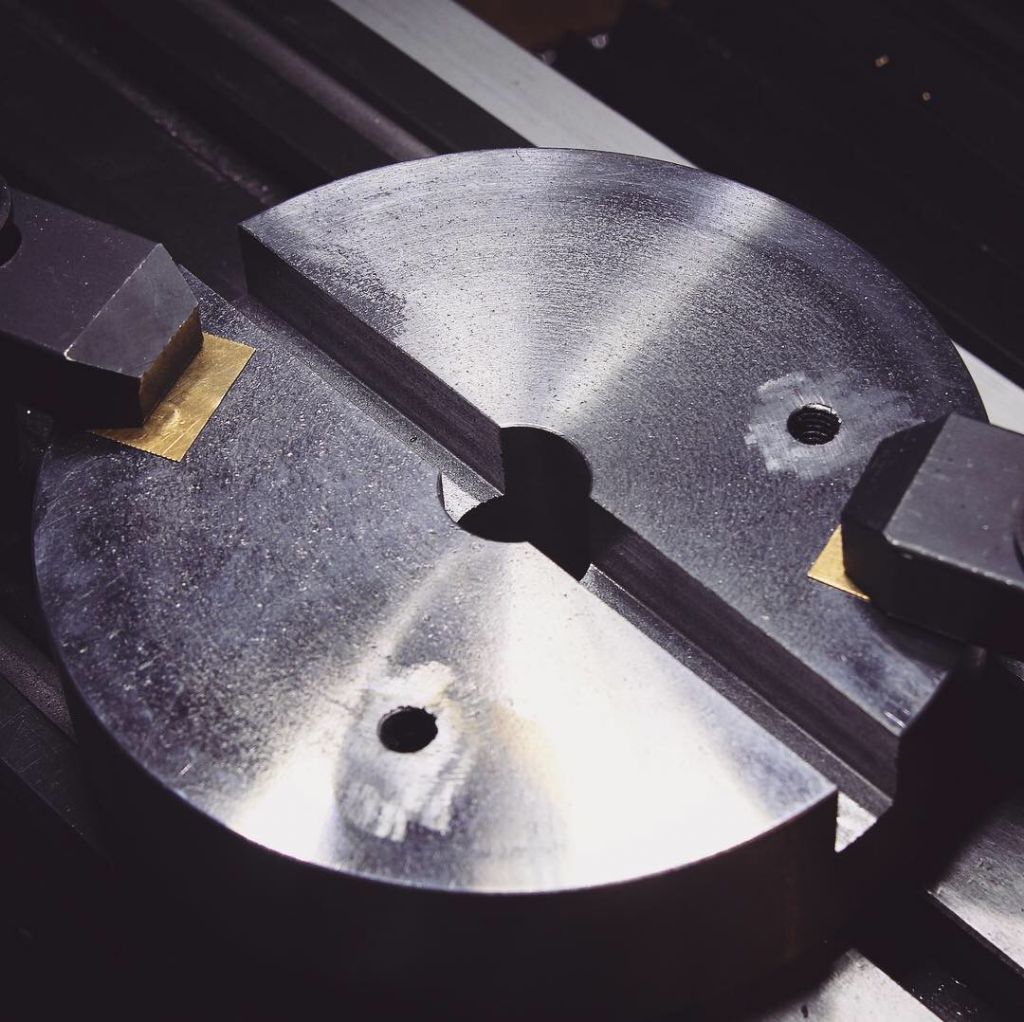

Unfortunately, I decided to build a 130mm 2 jaw/off-center chuck for my lathe and wanted to get it as good as possible to reduce the total error when it’s gonna be used.

The slot ended up being more than 0.1mm offset even though I centered it carefully. Does the 0.15mm make a difference that would prevent an engine from running, probably not. I still want to have it central

Hi Piotr,

Without knowing the details (cutter size and type, speed, feed rate, depth of cut, use of coolant, was the y-axis locked etc.) it's hard to be sure, but a likely reason is trying to cut the slot to size in one pass, possibly at too great a depth causing the machine to flex. I would argue such flex is a limitation of, rather than a fault of the machine.

Even a bridgeport would probably show some flex if you cut a slot that size in one pass, for example.

My approach to that slot would be to cut it to depth in a number of passes with a narrower cutter, then taking a sizing skim from each side.

Neil

19 February 2019 at 19:40 #397051Piotr

Participant@piotrHej Neil!

I cut that slot in what was perhaps 100 passes. I started with a small slot cutter 6mm, and cut it 6mm deep taking 1mm per pass. No cooling as this is regular cast iron and machined very well, just a vacuum cleaner not to breath in the dust and clean the slot while machining. Then I widened the slot using that very same end mill to 10mm, taking 1mm on each side during one pass. Later I repeated the same procedure and deepened the slot to 12mm total, and again widened to 10mm. Changed the enill to a 8mm carbide one and took 0.5mm on each side.. I could continue describing it but I think it’s enough to prove I did not in any way overstress the machine. Everything was done with a DRO and gage blocks for verifying progress.

Besides, after I discovered the offset I did check the column squareness with a grade DIN875-0 square and it was off. I already accepted the limitations of the machine. I will fix what I can, and the rest I will just have to work around if I ever want better accuracy.

Edited By Piotr Gertz on 19/02/2019 19:43:45

19 February 2019 at 19:44 #397053Ex contributor

Participant@mgnbukI was using a tool that produces a similar pattern finish to that shown in the OP today – a "soft" backing pad with fine abrasive disc on an angle grinder. The Biax power scraper (the machine tool fitters I used to work with refered to these as "diggers" ) produces a very different pattern, as Jason's picture shows.

I would be interested to have more details of the "scraper" that Sieg use, as I have not come across anything other than the Biax type in the UK. Given the price of Biax machines, something that does a similar job more economically would be of interest, though I suspect that I already have it.

Nigel B

Edited to banish the unwanted "smiley"

Edited By mgnbuk on 19/02/2019 19:46:19

19 February 2019 at 20:10 #397056Ketan Swali

Participant@ketanswali79440Posted by mgnbuk on 19/02/2019 19:44:51:I would be interested to have more details of the "scraper" that Sieg use, as I have not come across anything other than the Biax type in the UK. Given the price of Biax machines, something that does a similar job more economically would be of interest, though I suspect that I already have it.

Nigel B

Edited to banish the unwanted "smiley"

Edited By mgnbuk on 19/02/2019 19:46:19

Next time I am in the factory, I will try and remember to take a video of the machine in use, and ask them where they got it from. To be honest, JS and I saw it in use some years ago, and educated ourselves to the fact that it was a scraper which the factory is using, rather than an angle grinder (which was our initial impression). As both of us are familiar with the correct use of a hand scrapper, this came as a surprise which we weren't expecting at that particular time.

Ketan at ARC

19 February 2019 at 20:36 #397061 doubletopParticipant@doubletop

doubletopParticipant@doubletopProblems like these occur with every manufactured item.

In my RAF days the aircrew would have their favourite aircraft and go out of their way to avoid flying some. There would be aircraft that were forever in the hangar being fixed and others would go days, weeks without anything other than the regular servicing being done. No amount of changing components and fixing things would make a bad aircraft good. Maybe better but not good. The same went for the various components, some units would always be coming back in the servicing bays.

I’d suggest that very piece of equipment in our workshops is a compromise from rulers, through micrometres, callipers to the large machines. Fortunately, there’s enough info out there for us to be able to make an informed decision on what to buy within our budgets. Many of us were beginners and when we outgrew our initial choices we either fixed or replaced.

We purchase this Chinese equipment because it is cheap. If they didn’t supply the market we’d still be using vertical slides on our Myfords and probably not being as accurate or productive as we are now. Fair go to Ketan for fronting up and telling us how the supply chain works many other suppliers would shy away from making any comments.

Pete

Edited By Doubletop on 19/02/2019 20:37:59

19 February 2019 at 20:48 #397063Howard Lewis

Participant@howardlewis46836We can all afford a Box Brownie, but the best that I managed in later life was a secondhand Canon F1n, not the Leica 111G or M3 that I had yearned for all my life.

All through my various cameras, I got what I paid for. The more costly ones had more functions and performed better.

A machine should be "fit for purpose" but with respect to Neil, a Super Adept won't do what a mini lathe can.

For our hobby machine price range it is unrealistic to expect industrial standard of performance and accuracy. In any case, the levels of accuracy and repeatability would be beyond what we normally need, and the machine would be more reliable and durable. BUT it would show in the price..

I am not condoning a badly finished machine, (I have experienced cracked castings that have been painted over, in a machine from one of our fairly well respected importers. It went back for a refund! )

Maybe, Piotr's machine had some very rough handling in transit to Sweden, and before it reached him.

We shall never know. I have witnessed goods being dropped a couple of feet onto a concrete floor. Cannot imagine how that improves the goods.

Whether we realise it or not, at the time, we constantly seek to make a purse of some better material, (hopefully silk) out of a sow's ear.

If we accept less than perfection, we have to make allowances for the characteristics of that particular machine.

I do not expect every lathe like mine to deliver exactly the same performance. Some will be better, some will be worse. I happen to think that for what it cost me, mine is a pretty good machine. From time to time it exceeds my expectations, and very very often, my abilities.

The objective of Statistical Quality Control is to produce a product where a high percentage fall within one standard deviation of the mean.There will be, hopefully, only a minute percentage that fall into the outer ends of the bell curve. That task becomes more difficult as the product contains more parts and becomes more complicated.

Even space ships go wrong, sometimes with fatal consequences.

Rant over!

Howard

19 February 2019 at 23:58 #397084Hopper

Participant@hopperPosted by Piotr Gertz on 19/02/2019 08:06:18:Getting back to basics — and leaving aside the philosophy of hobby equipment in general (my $200 Nikon camera works just fine out of the box for taking hobby photos.) — I just had a look at the full video above, alleging a .1mm difference in height at the rear of one cross slide dovetail.

But I believe the test methodology is flawed and exaggerating the error by a factor of maybe 10 times or even more.

Hard to tell from the closely cropped video but it appears the DTI is mounted to a sliding block on the right, similar to the one on the left. The DTI is then mounted on a long arm. Further distance is added by the body of the DTI itself.

So what is being measured is most likely a very very very small twist in the right hand dovetail way, or even just a very slight burr on the rear right hand edge of the way surface. It would only take a variation here of less than .01mm to then be amplified by the leverage of the distance from the base to the tip of the DTI pointer. Easily a 10 times or more increase, judging roughly by eye.

So the .1mm reading obtained in the video is essentially meaningless. The ways are quite possibly just fine.

A more accurate way of measuring would be to sit the base on a surface table, set y up level as measured from table to way surface with a DTI on a sliding base, then compare it with the other way in the same manner.

But in the home shop in the absence of a large surface table, best method is probably as said in previous posts, set the machine up and measure the actual movements in action and then test cuts etc.

The important thing is to get the vertical column square in two planes to the cross slide way surfaces, then get the table X movement also square and the top of the table also in the same plane.

Setting up a machine tool is an extremely complex business. MC tool fitters spend four years as an apprentice learning on the job and at tech college so its not something you just sit down and do.

Reading "the bible" is a good starting point: "Machine Tool Reconditioning" by Connelly. Avoiding YouTube gurus is a good follow up. There are some absolute acts of ignorant barbarism being spruiked out there in relation to these small Chinese machines that you should avoid like the plague. (Eg lapping slides to ways with abrasive paste etc.)

If it were me I would put the machine back together, shim the vertical column square in both planes, tram the head and see how it went.

Edited By Hopper on 20/02/2019 00:00:03

20 February 2019 at 00:52 #397088Kiwi Bloke

Participant@kiwibloke62605Twelve hundred quid for a brand-new precision machine, and from China? Sounds too good to be true.

From what we see and read on many fora, manufacturing and inspection is so hit-and-miss that there are bound to be a few good 'uns escaping, but yer pays yer money and yer takes yer chance. A friend has a small Chinese CNC mill clone and thinks that it can work to micron accuracy. I haven't the heart to offer to do accuracy checks of the machine for him, let alone investigate cutter and work deflection under cutting loads, etc. Interestingly, the maker's spec. quotes 0.01 mm accuracy and 0.015mm repeatability. Not exactly jig-borer spec., is it? Neither is the price.

20 February 2019 at 05:43 #397092Alan Charleston

Participant@alancharleston78882Hi,

I have an SX2.7 mill and it has a peculiarity I'm not sure is a fault or not.

If there is a drill in the chuck but the mill is not turned on, and the quill is lowered using the handle on the right until the drill hits the work, it is possible to continue turning the handle a bit (say 2 degrees) until it comes to a hard stop. It's like the rack and pinion is really loose and a spring is used to keep the pinion at one end of the rack on the quill. This results in a tendency for the drill to suddenly drop a bit when the pressure comes off and grab when it breaks through the bottom of a hole. Is this normal. I did try to pull it apart to see if I could see what is wrong (if anything) but with the electrics in the handle to enable power tapping (a truly useless complication) I chickened out half way through and put it back together while I still could.

When I first got the mill, it came without the little bit of brass between the locking screw and the quill so I couldn't use it as a mill. The local supplier got onto Seig and as the part only weighed a few grams I expected them to mail the bit. No – they waited until they had a container full for the supplier – so it was about 3 months before I got it.

The other problem with the mill is the lack of oiling points. Unlike the SC4 lathe I was silly enough to buy which seems to have had a shotgun involved in the decision where to put the oilers, the SX2.7 only has one oiler – on the bushing end of the x axis screw for the table. It's really awkward trying to get the ways a screws lubricated.

Regards,

Alan

20 February 2019 at 06:56 #397095Piotr

Participant@piotrPosted by Hopper on 19/02/2019 23:58:22:But I believe the test methodology is flawed and exaggerating the error by a factor of maybe 10 times or even more.

Hard to tell from the closely cropped video but it appears the DTI is mounted to a sliding block on the right, similar to the one on the left. The DTI is then mounted on a long arm. Further distance is added by the body of the DTI itself.

So what is being measured is most likely a very very very small twist in the right hand dovetail way, or even just a very slight burr on the rear right hand edge of the way surface. It would only take a variation here of less than .01mm to then be amplified by the leverage of the distance from the base to the tip of the DTI pointer. Easily a 10 times or more increase, judging roughly by eye.

So the .1mm reading obtained in the video is essentially meaningless. The ways are quite possibly just fine.

A more accurate way of measuring would be to sit the base on a surface table, set y up level as measured from table to way surface with a DTI on a sliding base, then compare it with the other way in the same manner.

(cut)

If it were me I would put the machine back together, shim the vertical column square in both planes, tram the head and see how it went.

This is true, it could be twist. It doesn't, however explain why when tramming the column for left/right tilt I would get different readings depending on where on the table I put the reference square or if I move the table towards the column or the other way round.

I will put it on the surface place again when I go out again. Upside down on the ground middle surface and measure the difference of the sliding surface from underneath. The problem here is that it doesn't need to be flat as it's not a working surface, but there's no better reference to use. Alternative approach is to use jacks to level the four extreme points and see how it looks when swiping indicator across the ways then.

20 February 2019 at 07:07 #397098Piotr

Participant@piotrPosted by Alan Charleston on 20/02/2019 05:43:53:If there is a drill in the chuck but the mill is not turned on, and the quill is lowered using the handle on the right until the drill hits the work, it is possible to continue turning the handle a bit (say 2 degrees) until it comes to a hard stop. It's like the rack and pinion is really loose and a spring is used to keep the pinion at one end of the rack on the quill. This results in a tendency for the drill to suddenly drop a bit when the pressure comes off and grab when it breaks through the bottom of a hole. Is this normal. I did try to pull it apart to see if I could see what is wrong (if anything) but with the electrics in the handle to enable power tapping (a truly useless complication) I chickened out half way through and put it back together while I still could.

…

The other problem with the mill is the lack of oiling points. Unlike the SC4 lathe I was silly enough to buy which seems to have had a shotgun involved in the decision where to put the oilers, the SX2.7 only has one oiler – on the bushing end of the x axis screw for the table. It's really awkward trying to get the ways a screws lubricated.

I haven't noticed any problem with the quill. I can try that when I am in my garage again. I did however noticed similar behaviour with the head. It can suddenly drop when wound down, especially after the head lock was used.

The lack of oiling ports also surprised me too, but since the ways are exposed anyway it's not such a big problem to me.

20 February 2019 at 08:36 #397106 JasonBModerator@jasonbPosted by Alan Charleston on 20/02/2019 05:43:53:

JasonBModerator@jasonbPosted by Alan Charleston on 20/02/2019 05:43:53:If there is a drill in the chuck but the mill is not turned on, and the quill is lowered using the handle on the right until the drill hits the work, it is possible to continue turning the handle a bit (say 2 degrees) until it comes to a hard stop.

It's just a bit of backlash, between when the spring stops supporting the spindle as the drill makes contact and when the rack actually starts to apply pressure. The SX2.7 I have here does it as does my X3 and my drill press.

20 February 2019 at 09:03 #397115 Neil WyattModerator@neilwyattPosted by Piotr Gertz on 19/02/2019 19:40:25:

Neil WyattModerator@neilwyattPosted by Piotr Gertz on 19/02/2019 19:40:25:Hej Neil!

I cut that slot in what was perhaps 100 passes. I started with a small slot cutter 6mm, and cut it 6mm deep taking 1mm per pass. No cooling as this is regular cast iron and machined very well, just a vacuum cleaner not to breath in the dust and clean the slot while machining. Then I widened the slot using that very same end mill to 10mm, taking 1mm on each side during one pass. Later I repeated the same procedure and deepened the slot to 12mm total, and again widened to 10mm. Changed the enill to a 8mm carbide one and took 0.5mm on each side.. I could continue describing it but I think it’s enough to prove I did not in any way overstress the machine. Everything was done with a DRO and gage blocks for verifying progress.

Besides, after I discovered the offset I did check the column squareness with a grade DIN875-0 square and it was off. I already accepted the limitations of the machine. I will fix what I can, and the rest I will just have to work around if I ever want better accuracy.

Edited By Piotr Gertz on 19/02/2019 19:43:45

Thanks Piotr,

In that case it was indeed probably 'nod' of the column.

It's easy to see how travelling around the world in a container could result in movement in this joint, especially if this releases stress in a casting.

If you search on line you will find discussions of how to correct such tilt many brands of mill, it's not a situation unique to Chinese machines.

Neil

20 February 2019 at 09:10 #397116martin perman 1

Participant@martinperman1Posted by Ketan Swali on 19/02/2019 16:19:42:Posted by Martin Hamilton 1 on 19/02/2019 14:08:06:The certificates issued by most reputable factories are correct and issued after the machines have been assembled and accuracy adjusted after assembly, at the factory. We are regularly offered these certificates, and I have seen the checkers do their job to check the accuracy. But ARC refuses to accept these certificates because we don't know what will/will not effect the machine until it is installed. So, in this respect, the certificate is only true at the point just before the machine is packed in a 'reputable' factory, wherever it is from in the world. This holds more true for 'lighter' machines, built in this way. e.g. SX2.7 is light, and a Bridgeport is heavy.

Ketan at ARC.

As an ex machine tool fitter I would not be allowed to issue calibration certificates until the machine in question had been checked at the factory by the customer and then after it had been installed at the customers site after manufacturing test had shown the machine was as described and depending on the size and type of machine it could take days or weeks to acheive.

Martin P

20 February 2019 at 11:42 #397149Former Member

Participant@formermember32069[This posting has been removed]

20 February 2019 at 18:42 #397213 JasonBModerator@jasonb

JasonBModerator@jasonbBut all those Ha'porths add up.

All ways and surfaces to be hand scraped, add in heavier gears, higher quality circuit boards, another 50kg of iron and it WILL go on the price.

More expensive mills are out there like Ceriani and Webaco which are said to have a better build quality and demand a higher price but demand is far smaller. Even with the reasonably priced far eastern machines from our suppliers there are plenty of examples of hobbysts wanting to go direct to China to save a few quid more on machines that may very well be built to even lower standards.

Apart from John Mac's comment I have still not heard anyone suggest what is Acceptable accuracy for a hobby machine in these price brackets, anyone care to put their neck on the line. John Mac' suggested an accuracey of one handwheel devision in which case that slot at 0.01mm off was well withing the 0.02mm dial divisions, just because someone may stick a 1micron res DRO on there machine they should not expect it to suddenly work to 1 micron.

Is a person working with surface ground finishes and measuring with slip gauges just expecting too much from a Hobby machine in this price bracket?

20 February 2019 at 20:34 #397227Former Member

Participant@formermember32069[This posting has been removed]

20 February 2019 at 20:39 #397228Anna 1

Participant@anna1Ok. Dave. S.O.D.

Tell me where do I buy the Precision Mathews equivalent 9/35 mill, which is made in Taiwan, here in the Uk. As far as I can see nobody is importing Taiwanese machines. Which would be a good half way house in terms of quality

I have a similar lathe to you which is now ok with some work. My super major mill however, which is Chinese garbage which cost me over £3500 with dro was money down the drain. the Test sheet was work of fiction.( and it had nothing to do with the distorting casting red herrings etc.) If I just wanted to put a few electronic components in a box a drilling machine would do.

A recent poster has just paid £3650 for the vario super major which was clearly badly machined and not fit for purpose, for the most part all his posting got for his query, was criticism of his measuring technique, most unfair. I would be quite upset with the response he got. He deserves better.

Anna

20 February 2019 at 20:48 #397233 JasonBModerator@jasonb

JasonBModerator@jasonbAnna when questioned as to which of two measurement methods the poster had used he replied to using one method yet showed photos of the other method. Without seeking clarrification of how the results were obtained how else could people offer their views on what his machine was like?

20 February 2019 at 20:57 #397235martin perman 1

Participant@martinperman1The reason people buy Chinese is they are 'value for money' and – for many purposes – 'fit for purpose'. Has anyone ever proved by turning a mild steel rod to size that a Super 7 produces more accurate results than a mini-lathe? No. The Super 7 might do the job faster, but with a little care a mini-lathe will produce an identical result. For many people that's plenty "good enough".

Dave

I bought a second hand Clarke CL500M, which to many is the lowest of the low in the mini lathe world, and dont regret a minute of it, I manage to make parts for my stationary engines to the required tolerances required. I've had to tinker to make the lathe how I want it but working on machine tools is what I did in my working life, it cuts threads albeit a little fast and can produce a good finish when needed. I go to exhibitions and look at nice shiny new lathes and think can that do any better than my lathe at home.

Martin P

20 February 2019 at 21:02 #397236 JasonBModerator@jasonb

JasonBModerator@jasonbAnna, you might try XYZ Machine Tools their manual mills come out of Taiwan and also have the original makers "M" cast into them which can also bee seen on the PM machines though I think they start with the 9×42 table size.

20 February 2019 at 21:10 #397239Samsaranda

Participant@samsarandaChris, with the production of hobby machines there is always a compromise between cost and quality. To build a machine of high quality inevitably means a high cost to the customer, as I explained, to reduce costs the main castings are designed using the least amount of volume of cast iron that will achieve the physical envelope required, this means that the castings once machined are nowhere near as stable as those of commercial quality machines. The designer has worked to his brief to design for production within the cost envelope, this means that in all probability the castings will relieve internal stresses once they are machined, this is not to say that there is anything wrong with design or manufacture this is an expected consequence of minimalist designs. The equipment manufacturer would be aware of the consequences of this process and would, in so far as costs allow, build the machine and where possible adjust the components to minimise the errors. It is rarely possible with these hobby machines to produce a unit with zero errors, this means that machines in this price range may well have errors. Whether those errors render the product to be not of merchantable quality is dependent on the use to which it is being put, if the end user requires a machine capable of consistently holding very tight tolerances then a hobby machine is not the way forward they would require a commercial quality machine. Hobby machines are built to a strict cost and are offered as hobby machines not precision machine tools. We all obviously want the best machine for our hard earned cash but we must remember there is always a compromise of quality over cost and in choosing a hobby machine we have chosen cost over quality, I am sure that the overwhelming majority of hobby machines sold are deemed of merchantable quality, they are what they are and built to different standards than expensive commercial machines, we as the end users have to accept that they will not be the same quality as their expensive counterparts. Dave W

20 February 2019 at 21:26 #397243Anna 1

Participant@anna1Hello Jason

Thank you for xyz machine tool pointer

Regards

Anna

20 February 2019 at 22:05 #397248Ron Laden

Participant@ronladen17547Well thank goodness for Chinese hobby machines is what I say, without them I wouldnt have been able to make a start, I dont have the money or the space for anything bigger or better.

Yes they have their faults and limitations and even as a beginner I have come to recognise and accept that. I have done a few mods and upgrades on both the lathe and the mill in an attempt to improve them but straight out of the box they worked and worked well. I think they are great value for money and you cant expect a Rolls Royce for the price of a mini.

The question of how accurate hobby machines need to be, well mine have produced all the parts I,ve needed so far with some down to quite tight tolerances so I could argue that my mill and lathe are accurate enough.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Manual machine tools › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Help recommend a milling machine?

1

2

Started by:

richard1989 in: Beginners questions

- 20

- 29

-

6 August 2025 at 11:16

richard1989

-

MD65 leadscrew cross-slide stuck in nut

Started by:

leov

in: Manual machine tools

leov

in: Manual machine tools

- 9

- 18

-

6 August 2025 at 11:07

leov

leov

-

Pratt Bernard Grip true issues

Started by:

teamricky in: Workshop Tools and Tooling

- 7

- 10

-

6 August 2025 at 11:00

SillyOldDuffer

-

Smart Meter Change-over Problems

Started by:

Alistair Robertson 1 in: The Tea Room

- 7

- 7

-

6 August 2025 at 10:58

John Haine

-

F360 stock from solid

Started by:

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 9

- 13

-

6 August 2025 at 10:34

John Haine

-

Save your Swarf!

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 7

- 7

-

6 August 2025 at 10:20

Bo’sun

-

Depth of cut cowells me90

1

2

Started by:

kinross1 in: Manual machine tools

- 13

- 37

-

6 August 2025 at 10:15

Hollowpoint

-

Boiler Design – issue 4765

1

2

…

9

10

Started by:

Charles Lamont in: Model Engineer & Workshop

- 29

- 250

-

6 August 2025 at 08:53

JasonB

JasonB

-

Bandsaw vs Powered Hacksaw vs Chop Saw?

Started by:

MarkS

in: General Questions

MarkS

in: General Questions

- 17

- 20

-

6 August 2025 at 05:48

Perko7

Perko7

-

Collet identification

Started by:

David Colwill in: General Questions

- 7

- 16

-

6 August 2025 at 05:28

AJAX

-

Arc Euro Trade Ltd.

1

2

3

Started by:

Ketan Swali in: General Questions

- 54

- 65

-

5 August 2025 at 23:33

howardb

-

Cutting down a linear glass DRO encoder

Started by:

Robin Graham in: Beginners questions

- 9

- 17

-

5 August 2025 at 20:41

Mark Hall

-

Ultra Newcomer Lathe Setup Query

Started by:

Brahma in: Beginners questions

- 10

- 25

-

5 August 2025 at 19:49

Dave Halford

Dave Halford

-

Will iron rivets expand to fill oversized hole?

Started by:

Arthur Jones 2 in: Locomotives

- 6

- 6

-

5 August 2025 at 19:46

Robert Atkinson 2

Robert Atkinson 2

-

New Compressor

Started by:

Andy Brocklehurst in: General Questions

- 8

- 12

-

5 August 2025 at 19:40

noel shelley

-

14mm mild steel tube – I thought this would’ve easy…..

Started by:

Mick Bailey in: Materials

- 6

- 13

-

5 August 2025 at 18:48

Mick Bailey

-

MIG Welder Won’t Weld

Started by:

Martyn Nutland 1 in: Workshop Techniques

- 14

- 16

-

5 August 2025 at 17:51

simondavies3

-

New member (a young’un)

Started by:

tomread12 in: Introduce Yourself – New members start here!

- 5

- 6

-

5 August 2025 at 15:20

tomread12

-

Model Engineer Magazine Collection

Started by:

mfengine1 in: Books

- 9

- 15

-

5 August 2025 at 15:12

Norman Blackburn 1

-

Model Turbines

1

2

…

24

25

Started by:

Turbine Guy in: Stationary engines

- 28

- 610

-

5 August 2025 at 14:50

Turbine Guy

-

Precedent Perkasa MTB plans

Started by:

jamesrot in: General Questions

- 2

- 3

-

5 August 2025 at 14:21

Colin Bishop

Colin Bishop

-

UK Steel Supplier? 125 x 125 x 50 BMS

1

2

Started by:

MarkS

in: General Questions

MarkS

in: General Questions

- 13

- 26

-

5 August 2025 at 07:43

JasonB

JasonB

-

How many rings per piston?

1

2

Started by:

Arthur Jones 2 in: Locomotives

- 15

- 41

-

4 August 2025 at 23:59

duncan webster 1

-

Meek style dog-clutch for a Colchester

Started by:

Taris Jewell in: Manual machine tools

- 7

- 13

-

4 August 2025 at 19:51

Taris Jewell

-

Chuck- Lathe yet another type.

Started by:

Speedy Builder5 in: Workshop Tools and Tooling

- 9

- 9

-

4 August 2025 at 19:38

Pete

-

Help recommend a milling machine?

1

2

-

Latest Issue

Newsletter Sign-up

Latest Replies