Many thanks to everyone for your replies.

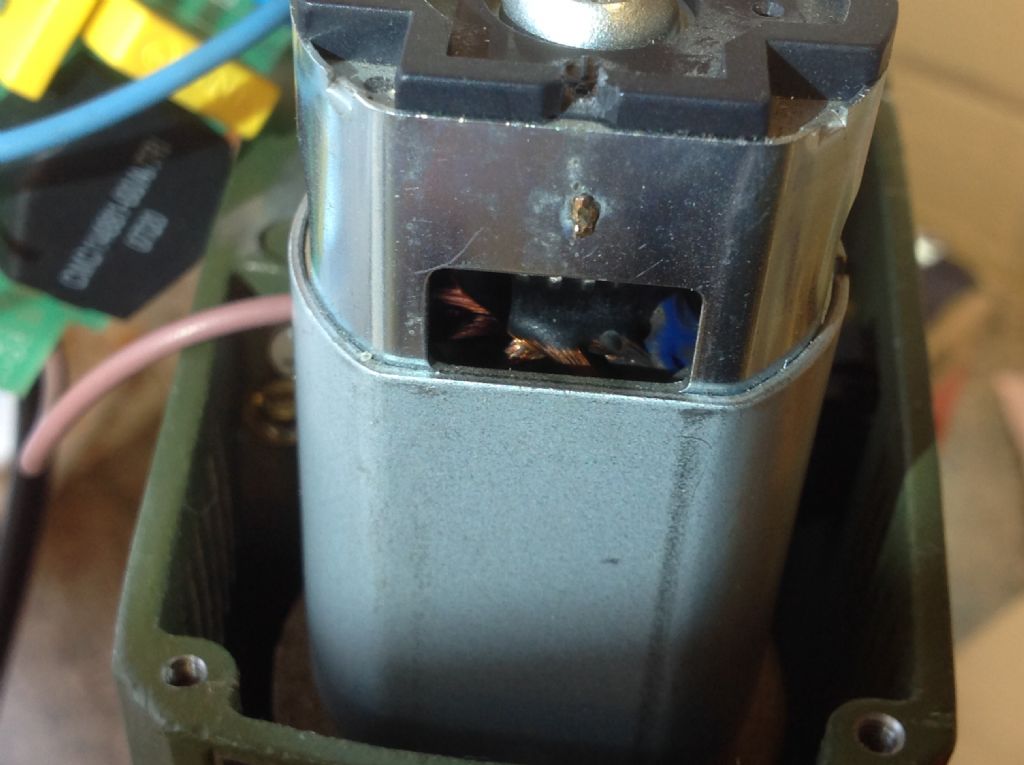

Michael, the motor appears not to be seized if the free turning (by hand!) of the spindle and commutator et al. is anything to go by.

JRow16, on the plus side your double failure of an MF70 makes me feel less unlucky than I otherwise might have done, but it has virtually sealed my unwillingness ever to put money into a piece of Proxxon machinery again. Was this the place you ordered the motor from: https://www.fluidonline.de/proxxon-28481-19-motor-mit-stuetzring-fuer-ib-e-ibs-e-ersatzteil/a-5776/.?

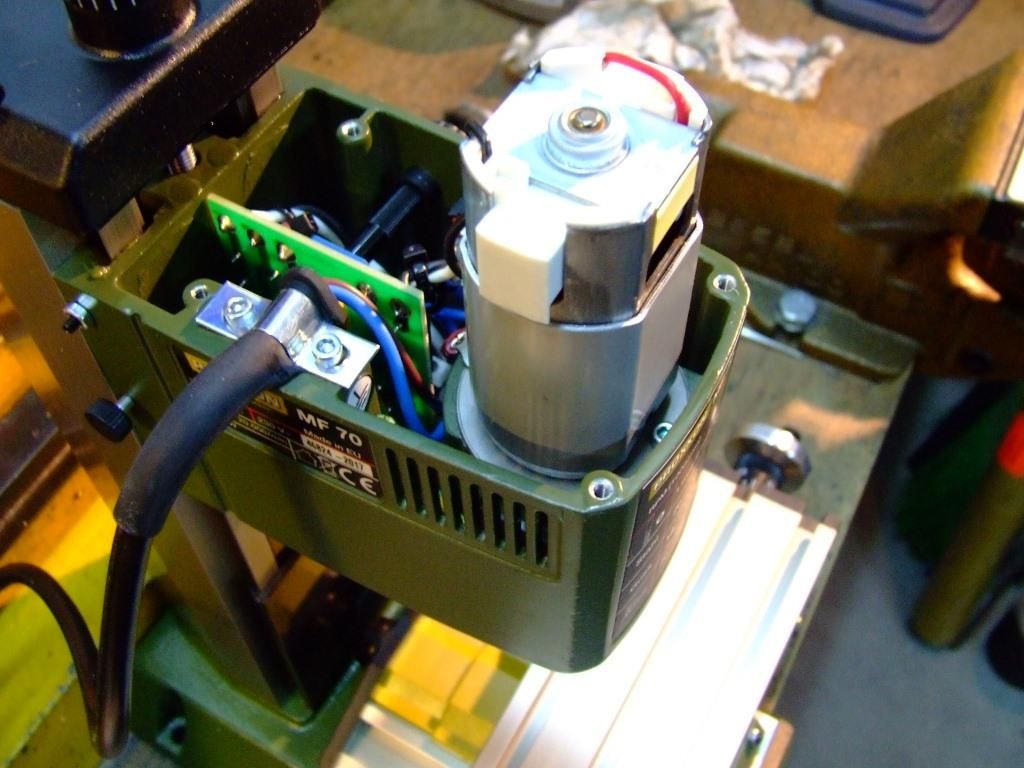

If so, I'm not sure whether it makes any difference, but the part number is one digit different from mine (which ends -11, not -19). While we're at it, I'd be interested to know how you uncoupled the old motor; I did try removing the two retaining screws at the base of the motor but it seems it can't be lifted away unless the spindle locknut is first removed, and I'm not sure how that's done.

John Paton, I wil try your second suggested test this weekend, thank you. I'll have to desolder the motor terminal wires anyway if I'm to do Tim's suggested resistance testing.

Tim, it turns out my brother has a decent quality multimeter and he used it only yesterday to check the resistance on his newly installed underfloor heating; I could always buy my own rather than wait till I see him next. I will try your suggested tests as soon as I am fixed to do so.

Posted by Martin W on 01/02/2019 00:22:30:

Bill

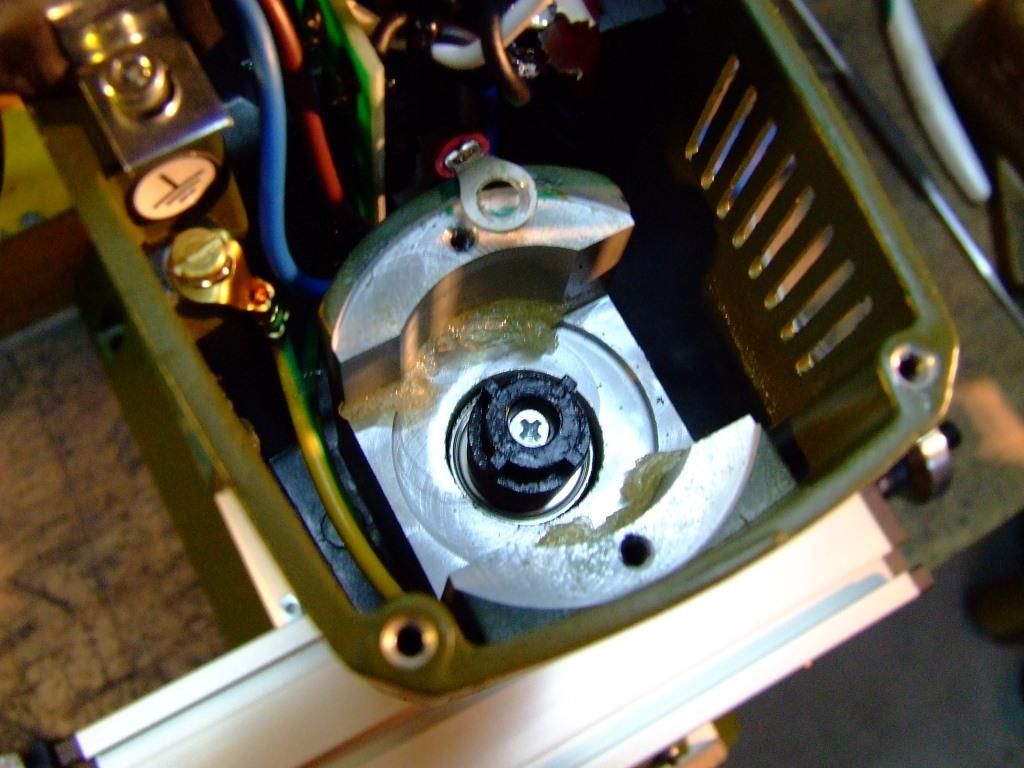

If you can do it safely then test the point at which the blue wire is connected/soldered to the pcb with the power on. If the neon lights up then you would appear to have a break in the neutral line to the mill. If there's no reaction then the neutral should be OK and we can discount the supply cable for the time provide the plug has been wired correctly.

Martin, I have just done this test, touching the screwdriver tip to the solder at the back of AC wire. The potentiometer was turned all the way up and yes, the neon illuminated. You say this would appear to mean a break in the neutral line. Can you tell me in simple terms how we know it means that, and how I can trace the location and or cause of the break?

Incidentally, can anyone tell me why this message occurs, which appeared multiple times when I attempted to post this latest post, and has occurred frequently in the past: "Your posting is 112556 characters too long, please split it into two or more separate posts".?

Bill Phinn.