Indeed with the mini-router. It was only intended for balsa and ply anyway – I have a Bosch for the bigger stuff. Thanks for the heads up about the motor & collet going too low!

Yes I understand the PWM set up (I qualifed in electronics a few years ago… When Marconi invented the radio…)

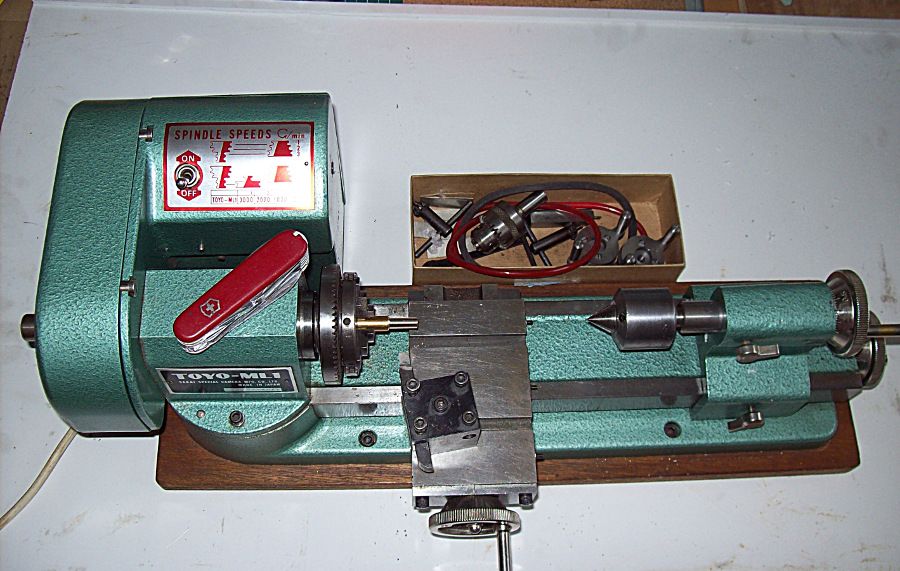

I'm keeping an eye out for the extras – quick change tool post, cross slide and vertical slides come to mind. I'm in no hurry as setting things up for when I retire. Yes it may be a few years off, but I have a plan!!.

I agree Proxxon are intended for the Hobby market, with a high price tag though. I was suprised at the 150/E though – overheating under no load… no current trip, just an awful smell! But, keeping an eye on ebay will bag you a bargain if you are careful. I have a large bandsaw and a 12" 1/2HP disc sander too, plus a Makita Flip saw which takes care of the bigger stuff. I have a feeling that when I retire I'll be ready for a Super 7… and a vertical mill, and a…….. and a …..

Edited By Stevo on 27/04/2014 14:57:29

Brian Williams 15.