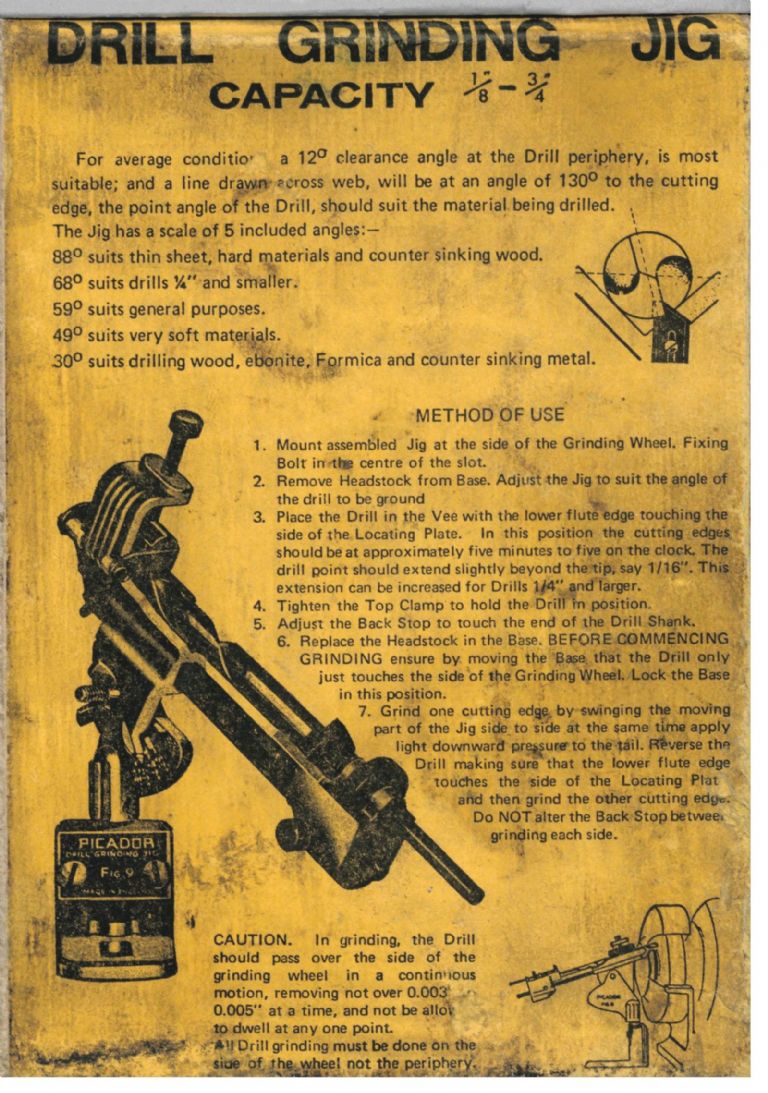

I have the Picador clone, Sears Craftsman 9-6677, 6* tilt toward wheel.

The link to Graham Meek's fix for tilted pivot is #404, aka quarantined.

I have the 180* stop and adjustable base micrometer-style mod implemented.

Should the drill bit cutting faces be vertical (align with parting line of tray casting) or 11 to 5 ? I noticed that the tray parting vertical line is not 90* to the Horizon (or my own instinct of vertical), but the parting line of course is constant, no matter how you look at or move the face of the bit.

Should a V insert be used to raise the bit above the tray on larger bits, or just a shim to shift the bit toward or away from the pivot axis? Or washers added between the base and compass to shift the axis?

Locating the tip of the bit at 12 on the clock (wheel) seems to deal with getting the grind to 90* to face.

Thanks for any help in locating Graham Meeks fix or for answering my questions. This is one of the best forums.

I am encouraged by how close I'm getting with all of the Forum suggestions and links, except this #404. I have no access to EIM.

Paul

Henry Brown.