Posted by Bazyle on 02/04/2018 10:18:27:

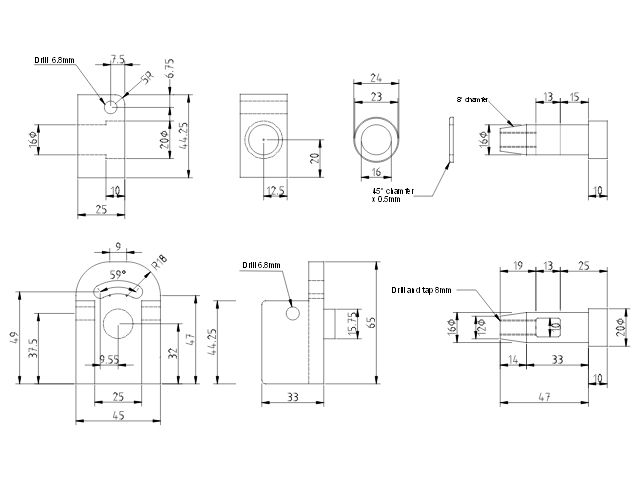

Looking at the drawing I see a 6.8mm hole drawn for the pivot pin. Unless the Perfecto is made differently for ease of manufacture for a hobby machine then this pivot is normally a taper pin which means clapper boxes cannot be made interchangeable. The taper is 1:48 and the hole through the lot has to be reamed together.

You might see if you club has a set of ME covering 2013 when there was a series about small shapers by Mick Knights where he mentions this.

Yes I remember Mick Knights article and the taper pin I know Mick had problems finding a source for them. On my Perfecto the pin is parallel by the look of it that's how it came out of the factory the pin is nicely blued and doesn't look home made, they must have decided that a taper pin wasn't necessary in this small shaper.

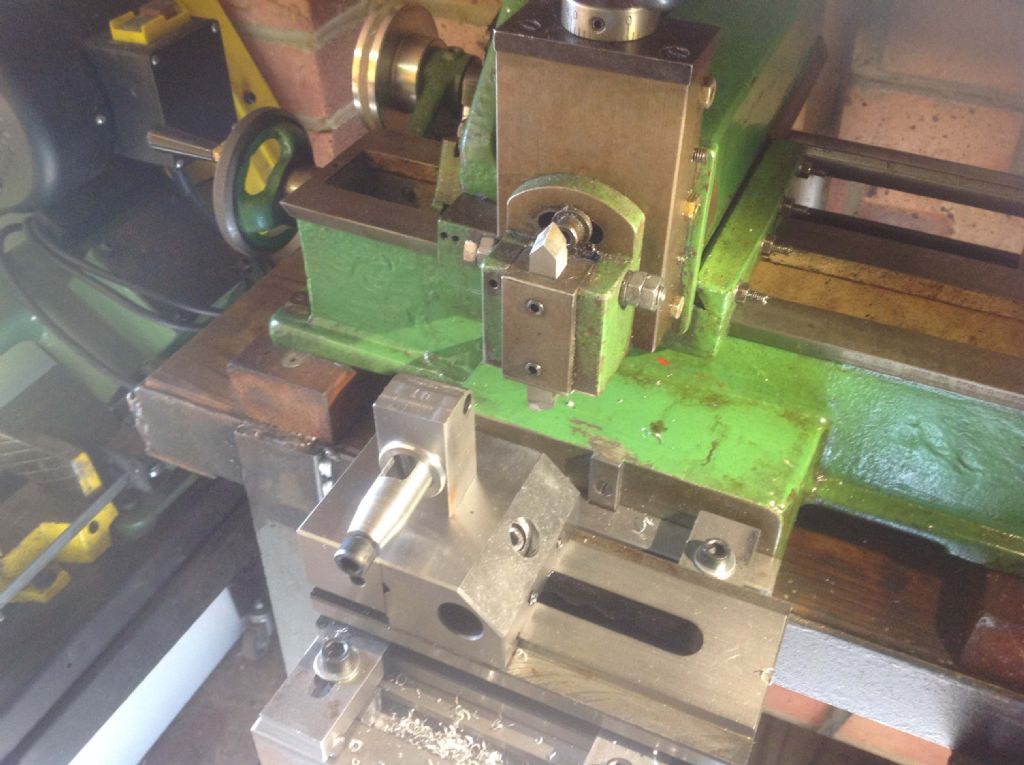

Any way I've got it fixed to the bench and I've had it running I've made a few test pieces and it cuts nice a square and parallel this is what I had to do to get it running:-

Base is a kitchen work top off cut

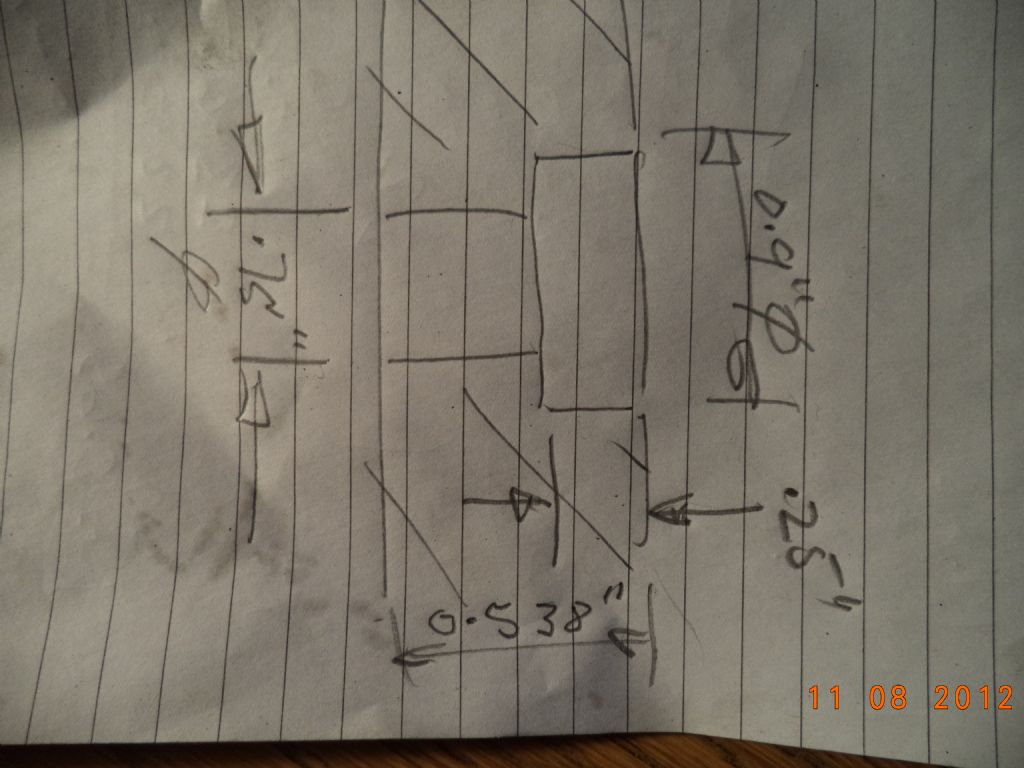

New tool Holder

Checked that the knee and T slots were square to the Ram

Then I squired the edges of the Knee to the base to aid set ups and drilled them so that I could use it as a clamp for larger flat plates.

Had problems getting the correct size V Belt the profile was the A type profile my pully's must be different to Johns Z Profile any way got one eventually that fits.

Made a bed plate for the motor and fitted it to the base.

The feed ratchet kept missing so stripped it down and found that the pawls were badly worn so I reprofiled them and after a bit of fiddling about got it working correctly

I've bought a nice machine vice to go on it, now I just need to use it a bit and find out how to get the best use out of it.

Stew

John Hinkley.

John Hinkley.