Posted by Niels Abildgaard on 01/02/2019 09:17:31:

…

I can either use a two pole motor and a 1 to 5 Poly v belt or a 1 to 2.5 SPZ belt .Both with a big disc diameter of 125mm.

What will make most noise and trouble?.

…

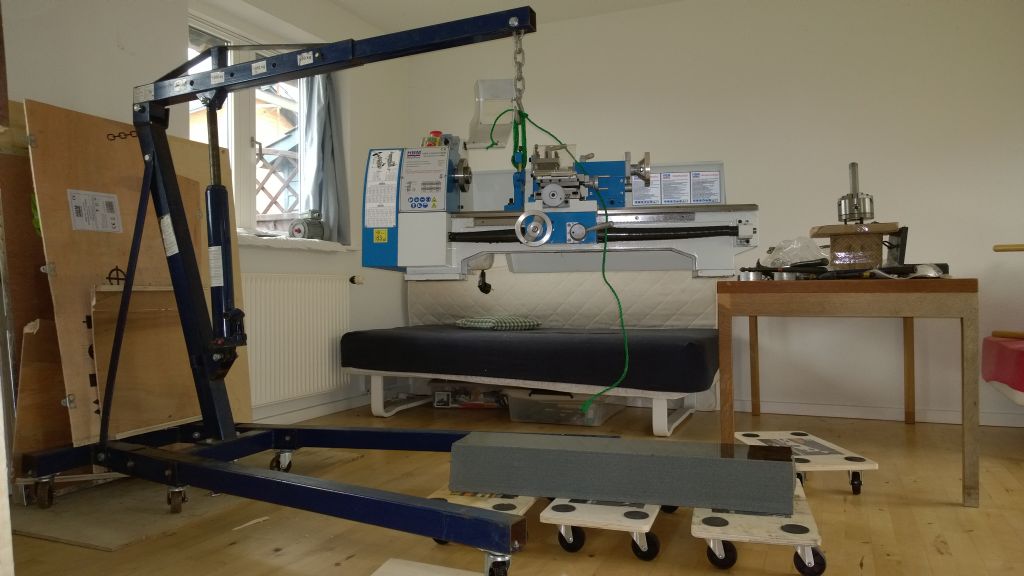

I have a WM280VF lathe – 1.5kW 3-phase motor with VFD, and a similar headstock layout to yours except the 280 has two pulley stages and two belts driving the spindle.

3-phase motors are quieter than single phase, but not by much. The motor is not the noisiest part of my lathe, motor noise being drowned out by other sources:

- A cooling fan on the motor that runs all the time allowing the VFD to turn the motor slowly without risk of overheating.

- A cheap computer-type fan on the VFD that runs all the time keeping the electronics cool. The VFD is silent, the cooling fan is noisy!

- The change gears are noisy. Carefully adjusting the gap between teeth much reduces the problem but the lathe is much quieter when they are disconnected.

- The lathe has a simple 3-speed gearbox – it too adds noise.

- The bearings aren't silent, the chuck stirs air at high speed, and cutting metal can be noisy!

The thing I miss most about my mini-lathe is how quiet it was! The bigger lathe is much more capable, but it makes about the same audio volume as my workshop radio. Not ear-defender loud, but the noise is an irritating hash and hiss rather than motor hum. A mini-lathe could be used indoors, a WM280 needs a workshop.

Removing the cooling fans would reduce the noise of my lathe considerably, but I'd rather have them. I don't think there's much to be done about the gears – they are made down to a price and break most of the rules needed for quiet running – not cut highly accurately, not accurately assembled, not suitably finished, not made of sound deadening materials, gear profiles not designed to reduce noise, not fully lubricated, and not fully enclosed.

Worth listening to your lathe to see where the noise is coming from – perhaps it is just the motor! A wooden rod used as a stethoscope is good for finding sources. I suspect switching to 3-phase + VFD won't reduce the noise much but don't be put off – 3-phase is better than 1-phase for other reasons.

Dave

Phil Whitley.