An excellent set of tooling there.

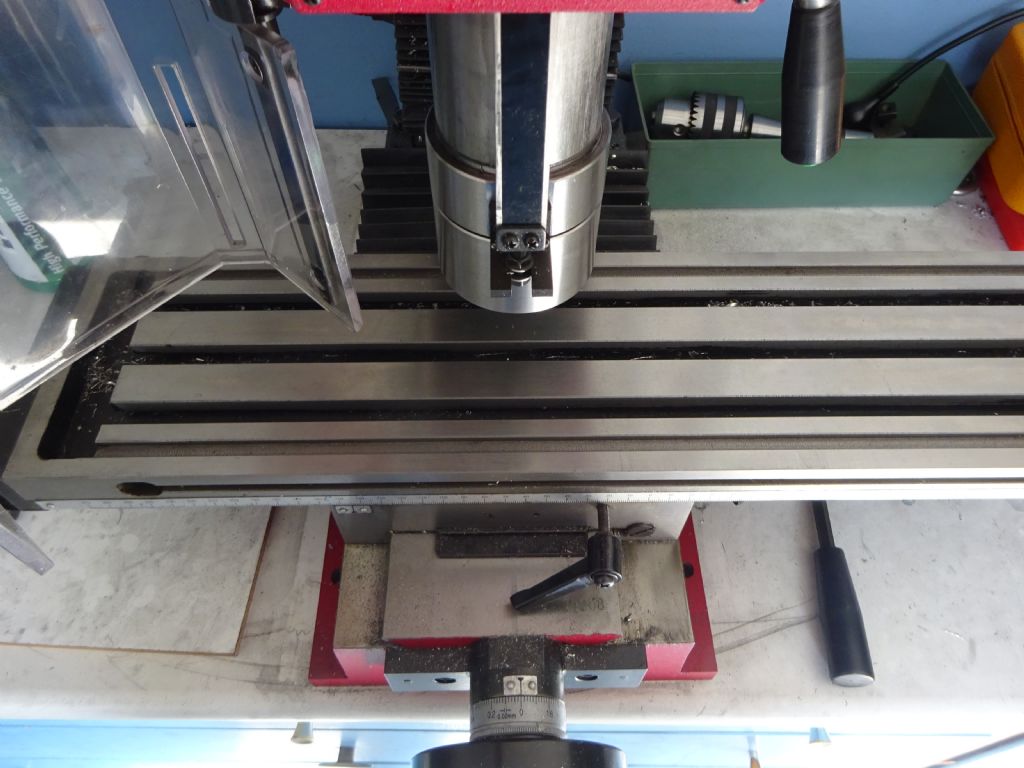

Referring to Paul Lousick's " I also spend …. time making jigs to hold the job. "

Whenever I make a jig, even of something a bit rough-and-ready for a simple, non-critical task on the bench-drill, I try to think " Can I also use this for XXX type of operation… " simply by , say, adding some extra mounting-holes, or making it bigger than for the immediate project so it can be modified readily. And doing so without undue extra time.

As an example, I needed an inner circle, so to speak, for the rotary table so I could round off the carriers on a Hemingway Kits boring-bar set. (My RT's T-slots end quite a way out from the middle.) While at it, I drilled and tapped quite a few more than immediately necessary of the clamping-screw holes, to cope with a range of similar tasks in future.

+++

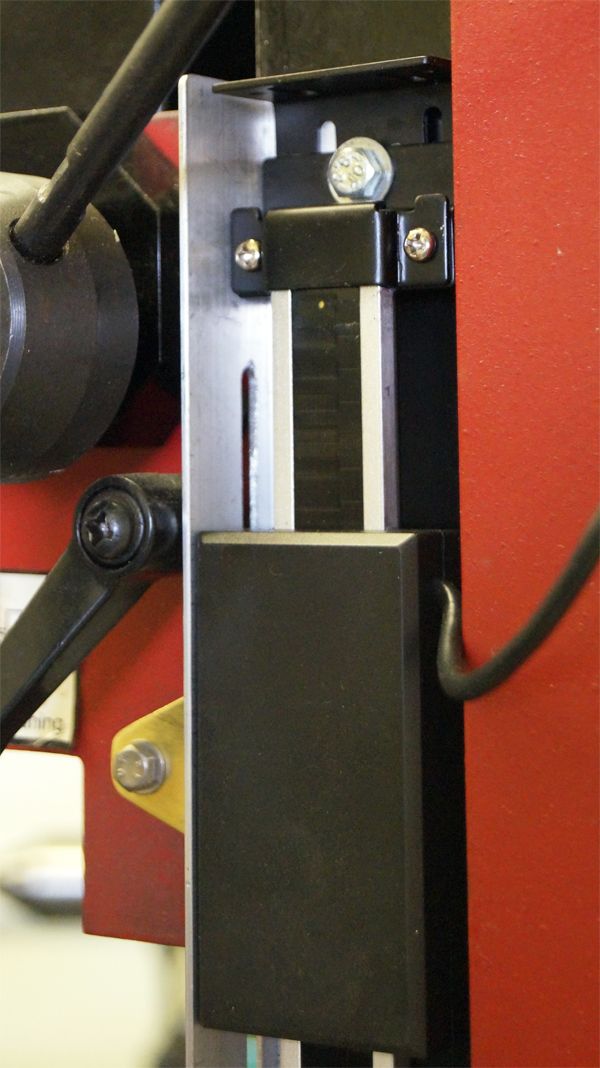

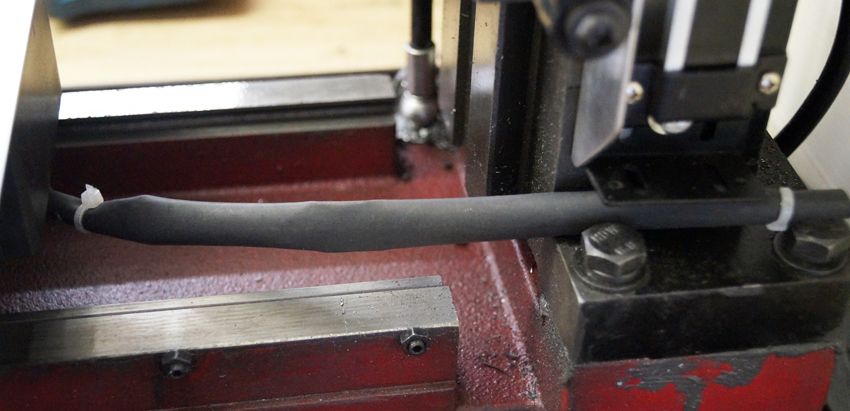

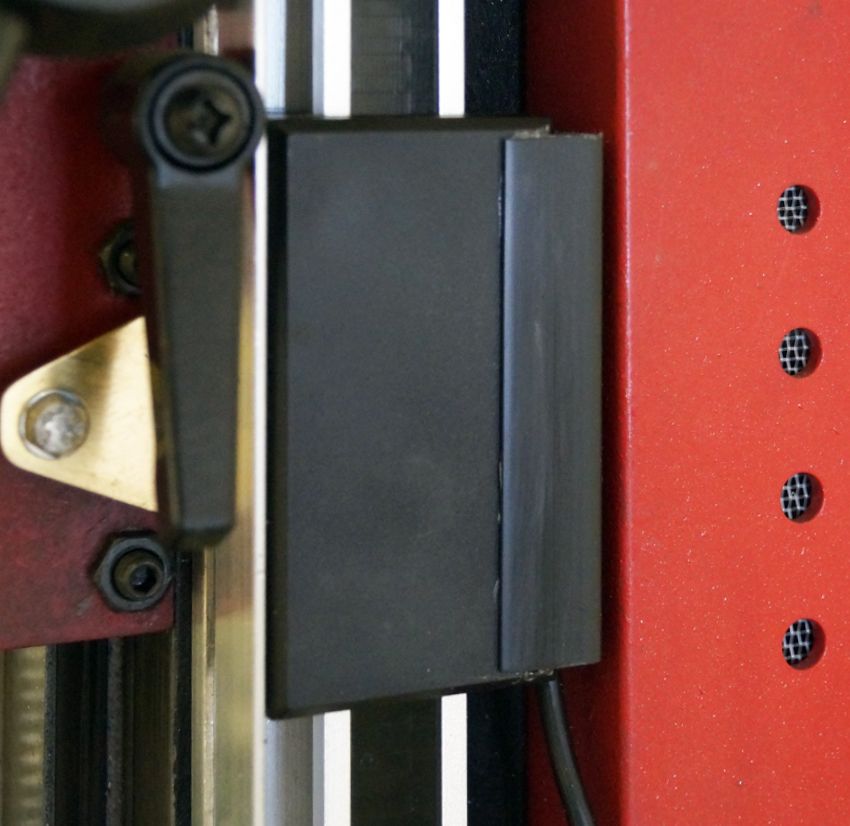

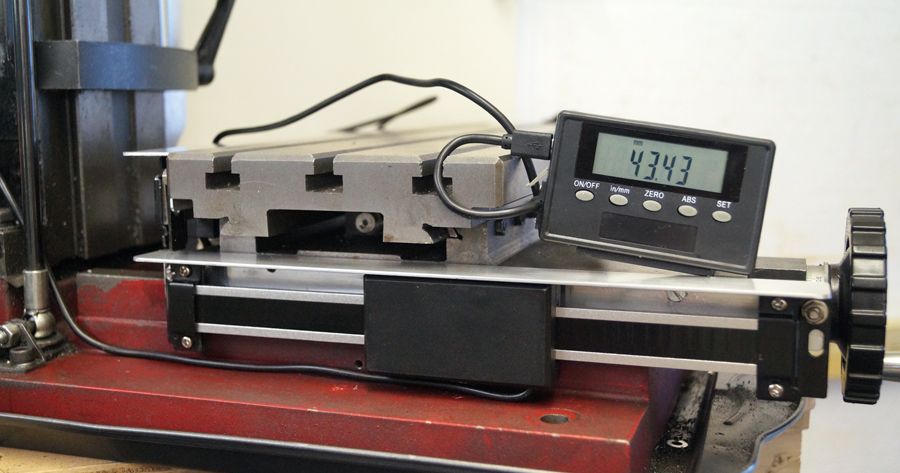

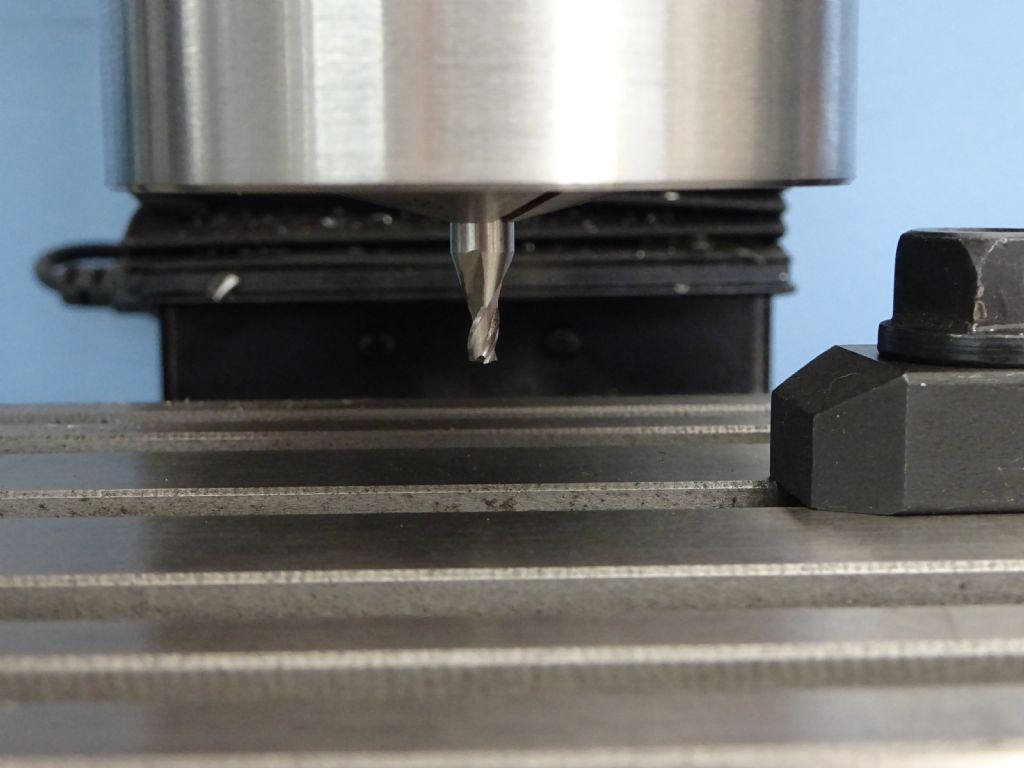

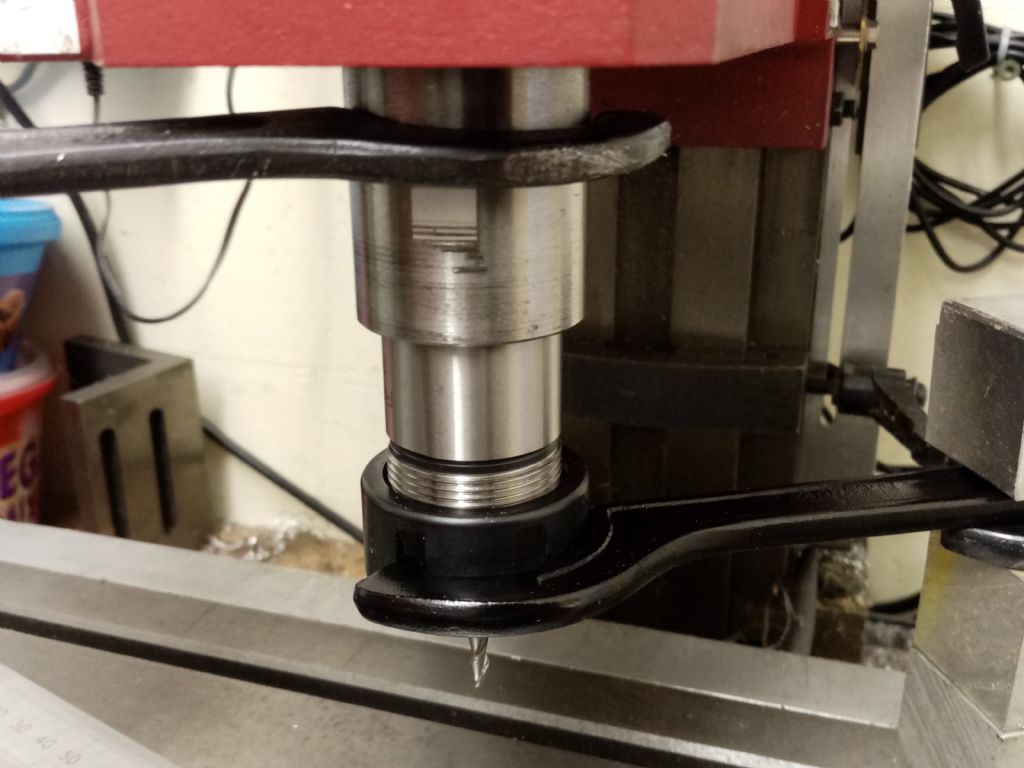

On Ron's remarks about protecting DRO scales, the Allendale Machine-DRO set I am fitting to my Myford VMC comes with lengths of purpose-made extrusion. Fitting the Y-scale cause me much cogitating (it's all right, it's allowed) and a lot of making of brackets and semi-rigid PVC-sheet cover . The Z-scale is even worse because the machine's column is a cast frustum of a pyramid, but I have worked out a mounting arrangement on large-section aluminium angle that also protects the encoder by a sort of " wrap-around " assembly. It puts the strip facing the wall behind the machine.

The set I purchased does have a pitch-circle calculator, but all is not lost without it because tables of (x, y) constants originally developed for setting jig-borers are available, and it would not difficult to create a simple spread-sheet in, e.g., MS Excel to rattle off the actual dimensions from them, the hole-count and p-c radius. easily.

Ron Laden.