There are a number of things I wont mention because they aren't worth worrying about that might be described as rather minor cost savings given the price. I do find that sort of thing annoying.

However

Bed design – there is no real reason why the bed couldn't have been designed to offer some main lead screw cover to prevent swarf from falling directly on it. They could have fitted a spring guard. They do on some models. I've bough a spring guard for it.

The cross slide could very usefully be a couple of inches longer, proportioned in that respect like real lathes are as I usually call them. I found that I couldn't face with a V tool when it was orientated for that as it couldn't reach the centre. The compound slide assembly can be moved to cure that but a longer lead screw and a simple extension that moves the feed handle out from the end of the slide would fix that – just as many lathes have.

A common problem that crops up if product designers are involved. The rack feed wheel is way smaller than it need be – probably so that it looks proportional to larger machines when it's photo'd. The other feed handles aren't too bad. I've bought another handle to fit to it – a myford one.104mm dia rather than 80 which will make a big difference for hand feeding.

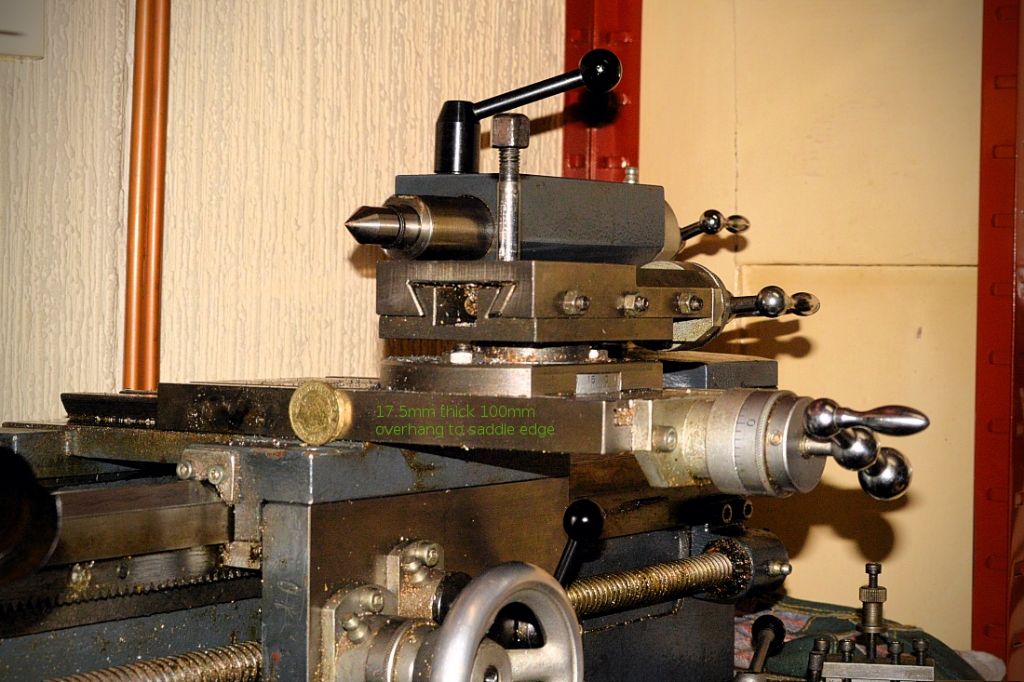

This one is complicated in some ways. Swings and roundabouts. The cross slide is T slotted outside of the dovetail so they don't add anything to it's height. These often have the problem that if anything is bolted down to them the dovetails distort and jam up the slide. It can be ok if what ever is bolted down and the top of the cross slide are dead flat. This is usually part of the numbers game as adding the T slot thickness needed to the top of the slide reduces the swing over it. So in this case it would reduce it to around sub 100mm rather than 120mm unless the head centre height was increased to compensate. The biggest chucks they supply are 125mm but the spindle head is designed to fit 100mm din chucks/ to some din standard *. A 120mm swing via a 125mm chuck is pushing it really anyway. The top thickness of the cross slide is pretty low so the compound slide has a plate under it that is bolted down in the T slots rather than a more usual arrangement – no plate and sitting directly on it. That needs a thicker cross slide top – as it would be with normal T slots. With the arrangement they have used clearance has to be provided to get at the fixing bolts so the actual compound slide sits on a pillar leaving rather a lot of overhang. All in all especially when the rather short cross slide is included a pretty bad piece of design work.

They note that it will swing 220mm over the bed but cross slide travel is 100mm. I'd guess that it will be hard to get a tool in a functional position any where near that diameter. It usually is on lathes of this style.

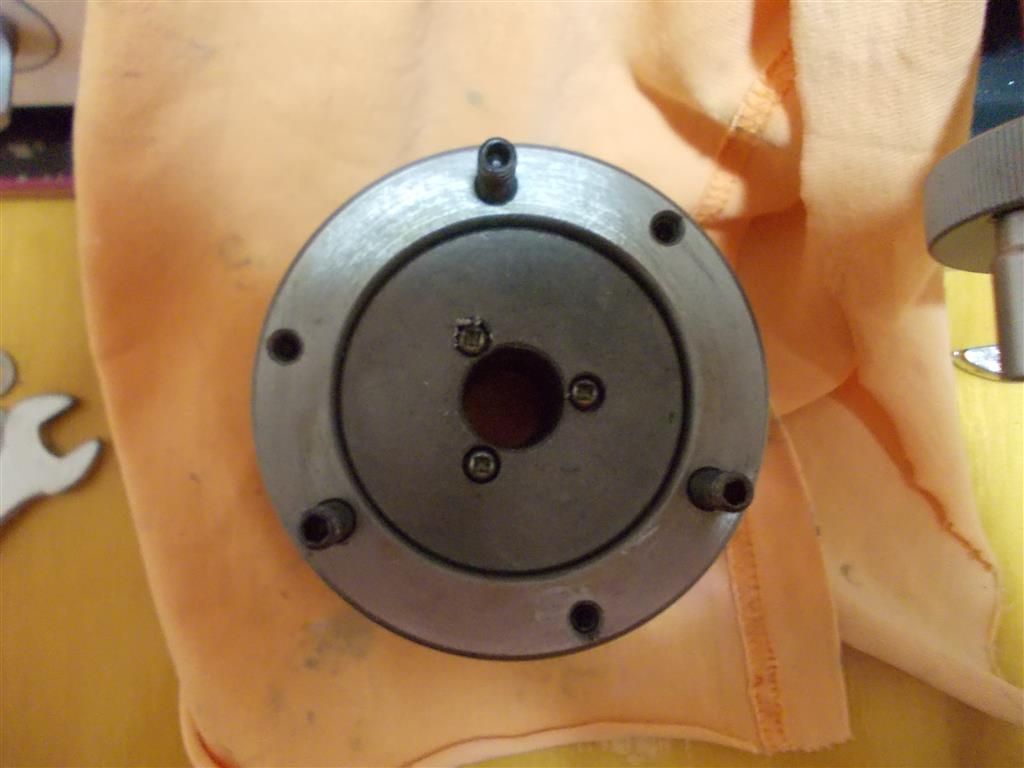

* Not sure about the translation of the chuck fitting on the spindle. I gained the impression that it was to a din chuck size to allow direct fitting. 100mm plate with a 70mm register. I happen to have a 100mm chuck that I wanted to fit to it but the register is much larger than 70mm. Not surprising as they needed to get the scroll plate in. So not sure what standard it's to. It looks to me that it does need back plates what ever chuck is fitted. But then DIN are often a weird lot. It's probably a spindle nose standard.

I'll post a photo that shows the shear stupidity of the cross slide design shortly. Can't now as I wouldn't be able to post it unless it was already in my album. It has to be there before a post is started.

Anyway I was aware of what I was getting into also the fact that as it was German that there would probably be catches. I can't get my DTI every where I need to to check alignment but a 3 morse mandrel showed no error along the top. Better than the test sheet that came with it shows. 0.0001" dti but that states push the spindle home if the bearings are loose. My test mandrel does have a draw bar hole for that but I lack the bits to clamp it with as they have to go round rather than on the other end of the spindle.

Anyway I was aware of what I was getting into also the fact that as it was German that there would probably be catches. I can't get my DTI every where I need to to check alignment but a 3 morse mandrel showed no error along the top. Better than the test sheet that came with it shows. 0.0001" dti but that states push the spindle home if the bearings are loose. My test mandrel does have a draw bar hole for that but I lack the bits to clamp it with as they have to go round rather than on the other end of the spindle.

John

–

marko veic.

.

.

Anyway I was aware of what I was getting into also the fact that as it was German that there would probably be catches. I can't get my DTI every where I need to to check alignment but a 3 morse mandrel showed no error along the top. Better than the test sheet that came with it shows. 0.0001" dti but that states push the spindle home if the bearings are loose. My test mandrel does have a draw bar hole for that but I lack the bits to clamp it with as they have to go round rather than on the other end of the spindle.

Anyway I was aware of what I was getting into also the fact that as it was German that there would probably be catches. I can't get my DTI every where I need to to check alignment but a 3 morse mandrel showed no error along the top. Better than the test sheet that came with it shows. 0.0001" dti but that states push the spindle home if the bearings are loose. My test mandrel does have a draw bar hole for that but I lack the bits to clamp it with as they have to go round rather than on the other end of the spindle.