Hi All

Thanks for the positive comments about the Acute Tool Sharpening System.

I've been having a look through the thread and thought I'd endeavour to explain a couple of questions that have come up about the sharpener.

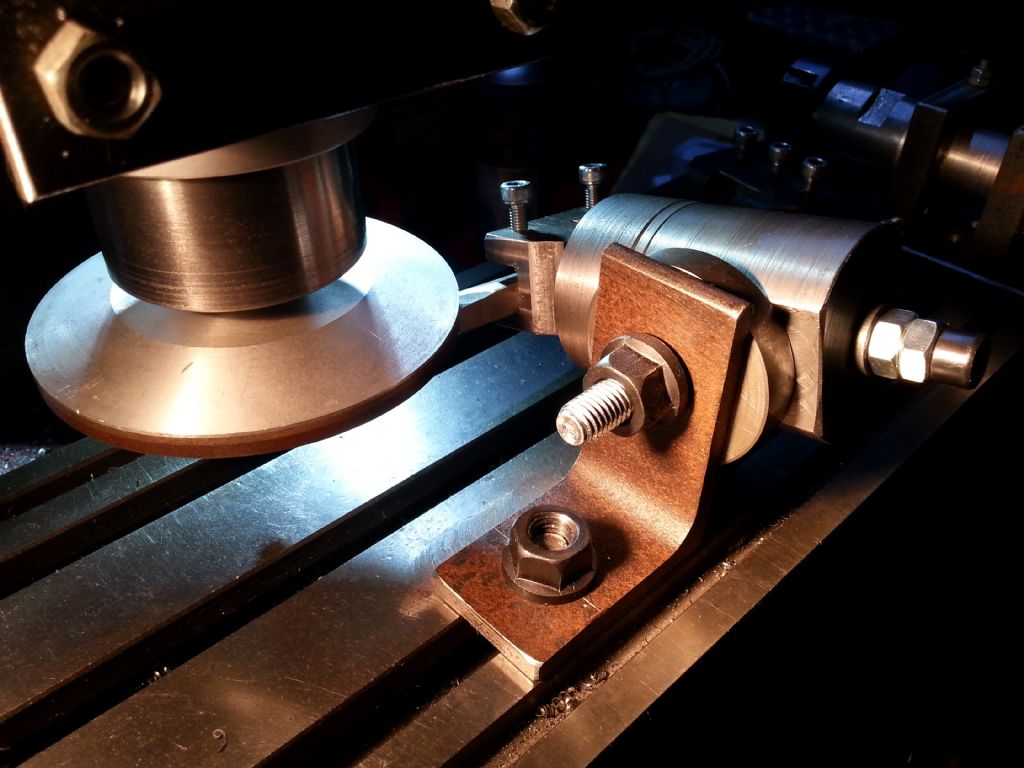

To try and minimise any slop in the links I have used Acetal bushes in the 6mm reamed holes in the links.

The bushes are about 0.1 – 0.2mm thicker than the link material and when you tighten the screw down on the bush it expands it enough to take out any play.

You can tweak the links this way so that they move freely but don't have any slop. It also helps to keep out grinding dust, doesn't need lubricating, and means the bushes can be replaced instead of the links if they wear over time.

Originally I tried using custom shoulder bolts and also bronze bushes. But as Neil mentions, you would have to make the parts extremely accurate as any clearance is multiplied through the four pairs of pivots.

Most of the holes in the laser cut components have been spot drilled to minimize marking out or the need for a dividing head or mill DRO. They are not through pilot drilled, just a 90 degree cone like a large centre punch mark about 2.5mm diameter done with a spotting drill.

I haven't put the drawings and kit up on the shop yet as I'm still trying to complete the DVD manual that comes with them on how to build and use the system.

I had hoped to have the DVD finished soon after returning from Harrogate, but I've been snowed under with a lot of other jobs at the moment.

Apologies to the customers who bought the drawings and kits at the show, I'll try and forward your DVD as soon as I can.

I'll put the prices for the various items on the UK distributor page as soon as they are finalised and the first batch of kits are shipped to my sister in Lancaster, she handles the sales in the UK.

I have a "What's New" page on the website so if anyone wants to find out any new information about the sharpener, other new products, or content on the website, they will be added to there. Just click our ad on the right hand side of this screen and click "What's New" in the menu at the top of our website.

Cheers

Gary

Eccentric Engineering

Howard Lewis.