Firstly, I'd like to thank everyone who replied. I expect all of you have a greater engineering knowledge than I. I did a little toolmaking on my violin making course during 2012-2016 and have only been doing more at home since then, firstly in a severely limited way with a Myford cross-slide fitted to my woodworking lathe (!), then with the Myford S7 I bought at the start of last year, and more recently with the purchase of the Sieg SX3 mill.

I knew the Myford was an old lathe with an unknown amount of wear, but I thought it was a great price (£1500) for one with a gearbox and power cross feed. It’s from 1982-ish, so the saddle is already ‘wide-guide’. I’ll try to reply to everyone separately below, so please excuse me repeating myself, and apologies for anyone I've missed!

Pete Rimmer: The idea of compensating for an out of line headstock makes complete sense to me. If the axis is pointing towards the back right corner of the lathe and the front right foot is raised to compensate, in my mind at least this would explain the barrel shape. Just an idea: would an iron casting such as a lathe bed spring back to its original flatness, or thereabouts, confirming this? If so, I could see what happens when I slacken the two nuts at the right end of the bed.

Unfortunately, I don’t have access to a machinist’s level, but if there is anyone on here who could help, in the Lincolnshire area, I would be eternally grateful. Having said that, it seems that not everyone is in agreement that it would help identify the problem.

Graham Meek: I’ve been using a freshly sharpened piece of 3/16” HSS held very solidly in a tangential toolholder made by a very capable young chap who is head of the engineering workshops at Newark college. He has given me a great deal of help, that is, until he fell off his push-bike and broke his hip at the start of the year! Anyway, I made sure the depth of cut was the minimum necessary to remove metal from all the way along the shaft, between 1 and 2 thou. The tool cut very sweetly with no chatter on the mild steel bar (not sure whether it was leaded for free-cutting, but it cut well). The cutter was sharpened with no radius, but has retained its edge during the eight or so test cuts, giving consistent results.

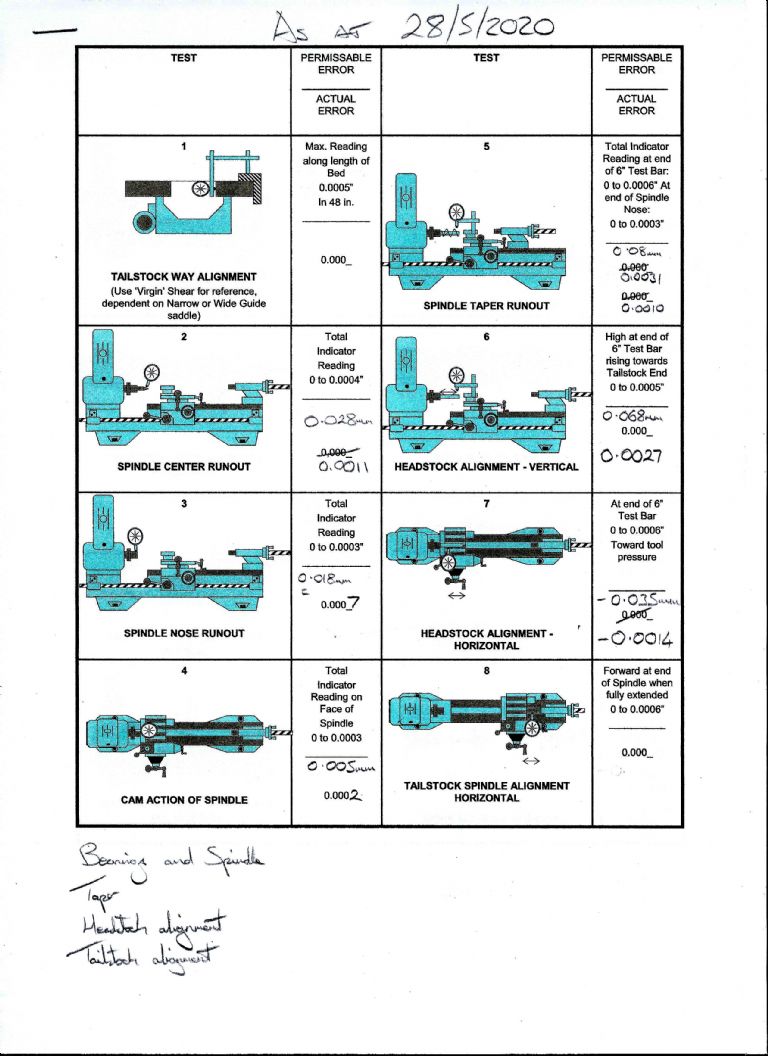

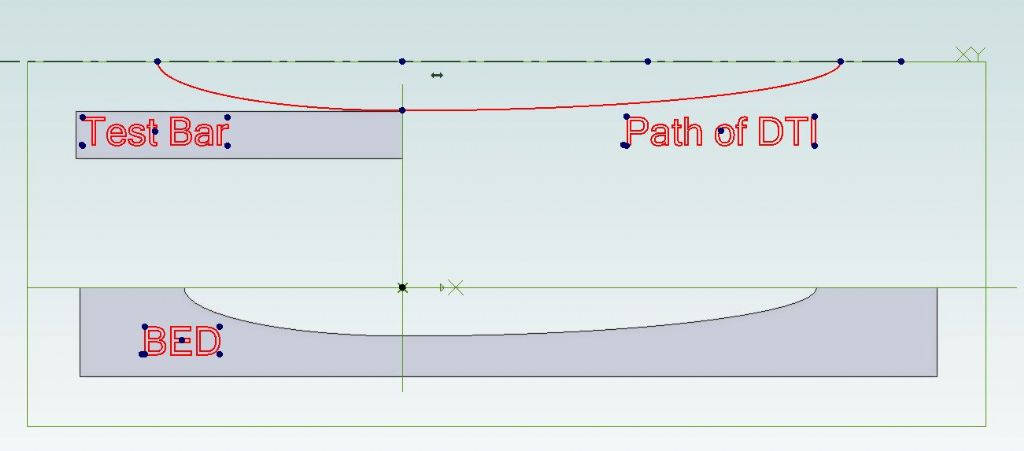

I’ll try the ‘test bar test’ tomorrow (I’ve been solving lockdown relationship problems today – my own relationship that is – very tiring!!) using the (probably Chinese) 11” (including taper) MT2 test bar from eBay recently. It’ll be interesting to see what this shows. I’ll keep you updated on my findings.

My overhaul so far has really only covered the carriage. The bed wiper felt was completely missing when I purchased the lathe, so this was the first job I did last year, as well as removing, thoroughly cleaning and oiling the saddle. The underside of the saddle is quite scored. More recently I replaced one of the apron bearings, which was so bad it leaked oil from the apron sump. Apart from adjusting the bearings and giving the whole machine a good clean and oil, I haven’t touched the headstock.

I have completely ignored the tailstock so far in my setting up since replacing the apron, as I considered its alignment to be just another variable to contend with and confuse issues further.. though more on this below.

(By the way, I have your handwheel dial fitted that I purchased from Steve Tracey – great design and a fantastic bit of kit!)

Martin Kyte: I haven’t noticed any rigidity problems with the ER40 collet chuck, going by the lack of chatter. The cut has been very light; no more than 2thou.

Blowlamp: I’m coming to the conclusion that it may well be just bed wear that I’ll have to live with, until I dismantle everything and have the bed reground, which seems to be worth considering. The lathe is from 1982 and therefore already has the ‘wide guide’ saddle, hence my taking the measurements from the full width of the bed.

I have absolutely no experience with metal scrapers, even though I do own several blunt ones. Without someone who knows what they were doing, I’d be afraid of doing more damage than good.

To be continued…

blowlamp.