Posted by Mark Whelan on 11/10/2016 13:23:35:

…

Appreciate the help, don't want to buy a lathe that no bits are available for

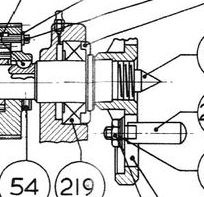

Everything is available for the M Type. Nothing particularly special on them. As said, chuck backplates are readily available and you simply screw them on the lathe spindle, turn the register step to match your choice of modern or used chuck and bolt the chuck on.

Plenty of M Type parts, and complete machines with accessories at knockdown prices, are on Ebay UK. That wuold include 3 jaw chucks from time to time. Change gears are readily available there too, as are just about all parts. No need to look for the special metric conversion gears as the standard set of change gears will cut all metric threads within tolerance more than adequate for home shop use. (See Martin Cleeve's book "Screwcutting IN the Lathe" , available cheap.)

Also, the yahoo group Drummondlathes is a great source of info and parts for these lathes.

Only a few ML7 bits will bolt straight across, but some accessories will, such as vertical milling slide and rear toolpost. One good mod is to fit a simply modified ML7 (ML10?) cross slide end bracket to allow about 2" of extra cross slide movement.

From memory, (getting dimmer all the time!) change gears and chucks and faceplates from the earlier Myfords such as ML2, ML4 will fit the M type with a little simple modification.

The M Type is my only lathe, used every week for whatever is happening in the shed and to me is every bit as good as many much newer lathes, and definitely better than some.

Edited By Hopper on 12/10/2016 09:06:13

ega.