Haklon, re your stand, before you construct it, I'd do a bit of research on the term "Levelling The Lathe"

This doesn't necessarily mean level with the earth's surface, rather making sure there is no twist in the bed, though being "level" in the spirit level sense is advantageous as well.

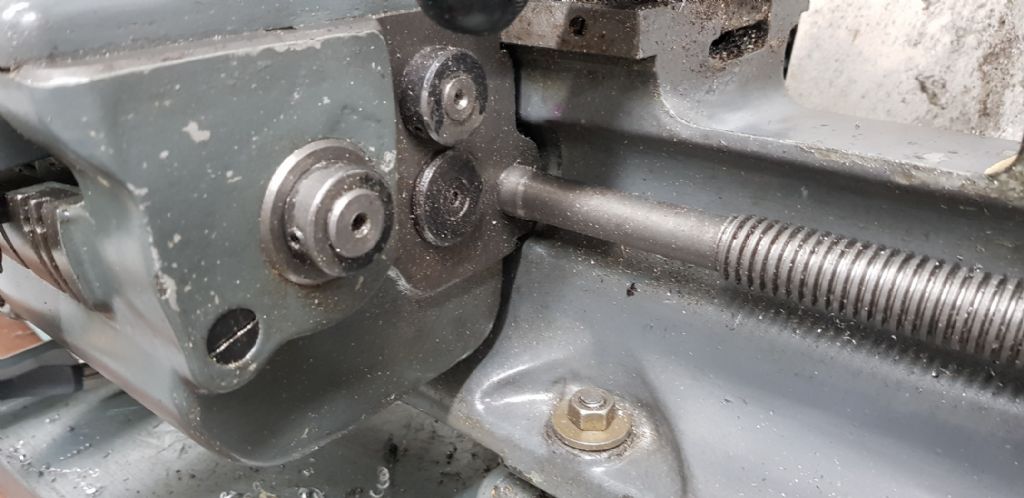

Essentially, the idea is, that in order to turn parallel, without tailstock support, the travel of the toolpost needs to be exactly parallel with the line of axis of the main spindle, for obvious reasons.

If the casting has moved over the years, or isn't bolted down correctly, then this could allow an unintentional twist along the axis of the bed. Maybe it was even bolted down unevenly in the past, and has taken on that slight set.

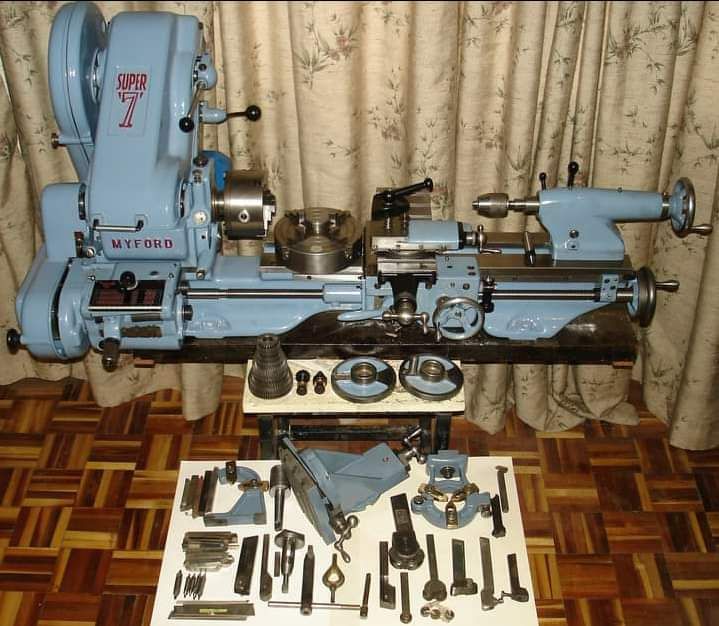

The Super 7 was intended to go on a rigid bench/stand such that, if the casting has twisted a bit since it was ground, then it is possible to correct that by differentially packing under the 4 mounting holes. Indeed the original Myford cabinets could add raising blocks which allow for this adjustment by using threaded tubular mounting feet (for want of a better term)

Looks like you've picked up a good and versatile machine there, well done.

Bill

It would be a shame to spend a long time making a folding bench, and then finding you couldn't get the lathe to turn parallel bars..

Edited By peak4 on 29/08/2018 01:25:05

Mike Crossfield.