Multi faceted drill bits – really necessary?

Multi faceted drill bits – really necessary?

Home › Forums › Workshop Tools and Tooling › Multi faceted drill bits – really necessary?

- This topic has 27 replies, 15 voices, and was last updated 3 July 2019 at 20:09 by

Howard Lewis.

-

AuthorPosts

-

26 June 2019 at 10:40 #416164

andrew lyner

Participant@andrewlyner71257I have recently bought a cheap and cheerful style drill bit sharpener (Draper). It cost less than £20 so I cannot really grumble. BUT, in learning to get results from it, I have come to the conclusion that the curved relief behind the cutting edge can be as much or as little as you want – just by altering the distance from pivot to wheel.

My relationship has been love – hate – love- hate – acceptance of the tool. I have read a lot of opinions about putting multiple facets on drill bits but, if the purpose is to improve clearance of swarf without compromiseing cutting edge strength, can't the same thing be achieved by a different curve? The side to side action of my sharpener produces a curve, determined by the spacing. I appreciate that a different sharpening method may produce flats so perhaps the cheapo method is, in fact the best way to go.

I do like a simple life and the four / six facet method sounds like real hard work for the jobbing amateur. A lot of effort is involved to save a short amount of cutting time per hole.

Edited By andrew lyner on 26/06/2019 10:40:37

Edited By andrew lyner on 26/06/2019 10:41:41

26 June 2019 at 10:40 #19386andrew lyner

Participant@andrewlyner7125726 June 2019 at 10:55 #416167 JasonBModerator@jasonb

JasonBModerator@jasonbA 4 facet drill will have a more pointed end, if you just grind the whole end at one angle the web between the flutes will still be long so takes more effort to drill with and it won't self ctr so unlike a split point drill you will need to punch or spot drill first.

Edited By JasonB on 26/06/2019 10:57:57

26 June 2019 at 11:06 #416168 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattThe main difference is as Jason says.

Four facet drills cut better and more accurately than conventional ones. Split tip ones are even better.

The issue is that more facets take longer so industry likes the curves which can be done with only a single flip of the blank.

In the workshop where good results are a priority over saving time, four facet is an easy way to get accurate easy cutting drills.

I still haven't seen a simple way to grind split point.

Neil

26 June 2019 at 11:11 #416170Anonymous

All my standard metric drills are Dormer 4-facet. Probably 90+% of my drilling using them. As Jason says you don't need to faff about with centre popping or drilling with a 4-facet drill. Provided of course that the surface is flat and reasonably smooth.

In 12+ years I've only renewed a handful of the Dormer drills, mostly small ones becaise I've broken, or lost, them. Some have worn out, although they're good for many hundreds of holes before needing replacement. The smaller Dormer drills are so cheap it's utterly pointless wasting time sharpening them; I just buy new ones from Greenwood Tools.

Way back when I was a small kid I used to sharpen drills freehand. Although I've now got a Clarkson and a drill and tap grinding attachment I've never used it for drills so far; taps yes but not drills.

Andrew

26 June 2019 at 12:41 #416191andrew lyner

Participant@andrewlyner71257I'm not sure that my idea has been appreciated. I will need to try carefully grinding a test piece and see where I am wrong (or vaguely possibly right) in my opinion. Thinking in 3D is hard.

I do understand how the appropriate grinding could eliminate the need for centre popping.

26 June 2019 at 13:09 #416193 JasonBModerator@jasonb

JasonBModerator@jasonbI think you will find that whatever radius you swing the drill at you will never reduce the central web. As this hardly has any cutting speed it is just like rotating a solid bit of metal into the work so that is what takes the effort.

Think how much easier say a 12mm hole is to drill if you have previously drilled say a 3mm pilot. You are still removing something like 95% of the metal with the 12mm bit but it probably needs about half the effort. Self centering is just a bonus.

Like Andrew I tend to use the Dormer A002 and stub length A022 drills, they call theirs split point but they are realy just 4-facet with a bit more behind the cutting edge than the one I showed above, not the reduced web again. When I do us ea spot drill I also use ones with a thinned web which chut easier and won't wander even on light machines

Dormer "split point"

Edited By JasonB on 26/06/2019 13:13:27

26 June 2019 at 14:11 #416199Clive Foster

Participant@clivefoster55965Andrew

You can indeed vary the curve after the cutting edge by changing the projection distance of the drill from the pivot axis. Unfortunately there are three interrelated variables that determine the shape and sharpness of the drill. Changing any one of them effects the overall result. If your sharpener is made adequately accurately and following best practice book values for drill projection will give you the closest approximation to factory shape and performance. Of course when it comes to the cheaply cast imported devices that is a very big if. It doesn't help that the original design, from either General or Spiralux, is fundamentally flawed in that it is overly reliant on the user setting the correct projection distance with inadequate information.

Geometrically speaking its a horribly cheapened down (AKA made affordable) version of the Atlas drill grinding jig see :- **LINK** but note, despite what it says below the pictures, that the Picador version has a vertical pivot and works differently.

Obviously the drill point moves in a circle as the pivot is swung. The further out the drill sticks the larger the radius of the circle and hence the less the clearance angle. The fundamental requirement is that the clearance angle be great enough to prevent the heel of the drill contacting the bottom of the hole being made. If it does the edge will be jacked out of cut.

The carrier Vee is offset behind the pivot point axis so that a sharp cutting edge is made when the drill moves across the wheel. The point is little behind the diameter of the swing circle. Simply swinging in a circle won't generate enough clearance. The angle generated will run side to side across the drill rather than around the edge. Tilting the pivot axis increases the depth of grind the further the drill is swung giving, within limits, an adequate geometrical approximation to the factory shape. It also makes subtle variations in grind geometry to cope with different size drills. Obviously all three :- drill point offset, pivot tilt angle and drill point projection interact to define the final shape of the point. But its all a compromise, especially when you factor in the different point angle settings. With the tilted pivot types you are expected to adjust the drill projection to get best results. Best results for one breed may not be the same as for another as there is some leeway in the exact dimensions and angles provided on the tool needed to give a satisfactory approximation to the correct shape. But they do have to be pretty much a matched set. As has been said on other threads many cheap imports are so erroneously made that correct geometry is impossible.

The Atlas version has a nice scale to help set point projection for its particular geometry. Which makes life much easier. The Picador, vertical pivot, version puts the drill edges at 5 to 5 in rotation. In conjunction with the edge stop this sets the projection more or less automatically. The original PlasPlugs system uses geometry similar to the Picador and includes and effective projection setting gauge on the tool. It also has a flip over tool carrier guaranteeing that both edges are correctly set with each other. The PlasPlugs variant is the only inexpensive version of these tools that can be considered engineeringly acceptable and reliably functional. Possibly unfortunately the range of drill sizes is more limited and only one tip angle is possible. I think the later versions have been cheapened and dis-improved.

The four facet system sidesteps the whole problem by using straight grind at a sufficiently steep clearance angle to ensure that the heel is always clear of the hole. The big problem with 4 facet points is that they cannot be replicated by hand and must be machine ground with the drill point accurately centred. For reasons I don't understand its always been considered impossible to produce an inexpensive four facet system. It is, of course, obvious that moving the edge of a correctly aligned drill vertically across the periphery of a grinding wheel will give line contact between wheel and drill allowing the correct flat to be made. Given a mount providing reliable flip adjustments for both edges and both angles a correct point must be produced if the drill is mounted with the cutting edges aligned horizontal i.e. at 90° to the movement.

Clive

Edited By Clive Foster on 26/06/2019 14:13:32

Edited By Clive Foster on 26/06/2019 14:14:26

Edited By Clive Foster on 26/06/2019 14:16:01

26 June 2019 at 14:50 #416210andrew lyner

Participant@andrewlyner71257Right. That makes sense. There's nothing to ensure that the curve that's generated by the pivoting jig will be optimal. I see that now. The four facet method can, at least, get the angles better.

I have to say that, despite the unimpressive ricketiness of my new jig, the drills seems to work better than my variable manually ground attempts. If and when I start to need more accuracy, I shall need to re-visit things.

I notice that people make very adverse comments about overall quality of what most of us use as a matter of course. Lathes, Milling machines and drills would be out of the reach of most of us if we felt that we absolutely had to use British Made. We all appreciate that we could be playing Strad Violins, driving Ferraris and holidaying in top hotels but we are in the real world. Actually, it would be totally unrealistic for a beginner to be using top grade things because it could end up as a waste of all that money if they fell by the wayside.

The criticisms about bad quality equipment could easily be implied criticisms of less well-off and less qualified users. I am bullish enough not to worry but I do wonder about how some other beginners could feel 'guilt' about only buying the cheapest stuff.

26 June 2019 at 15:47 #416220 Gary WoodingParticipant@garywooding25363

Gary WoodingParticipant@garywooding25363I purchased a Sealey SMS2008 drill sharpener a few years ago – it works really well. The link is a demo.

26 June 2019 at 16:12 #416223 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattPosted by Clive Foster on 26/06/2019 14:11:25:

The original PlasPlugs system uses geometry similar to the Picador and includes and effective projection setting gauge on the tool. It also has a flip over tool carrier guaranteeing that both edges are correctly set with each other. The PlasPlugs variant is the only inexpensive version of these tools that can be considered engineeringly acceptable and reliably functional. Possibly unfortunately the range of drill sizes is more limited and only one tip angle is possible. I think the later versions have been cheapened and dis-improved.

The four facet system sidesteps the whole problem by using straight grind at a sufficiently steep clearance angle to ensure that the heel is always clear of the hole. The big problem with 4 facet points is that they cannot be replicated by hand and must be machine ground with the drill point accurately centred.

I've got a PlasPlugs grinder, I'd say it is fundamentally well thought out, but suffers from a tiny grinding wheel and flimsy construction. A beefed up metal version could be good.

You can grind larger 4-facet drills by eye or with a basic guide to set the cutting edge angle, the second relief angle is not critical as it should not touch the work. I find it easier than traditional offhand grinding of drills.

Neil

26 June 2019 at 20:27 #416248Pete Rimmer

Participant@peterimmer30576The main reason for 4-facets instead of just 2 is if you were to only cut the primary angle the tool will foul the work at the heel (behind the cutting edge). The secondary angle (which creates the four facet drill) is necessary for that extra clearance.

26 June 2019 at 22:54 #416263Clive Foster

Participant@clivefoster55965Neil

Regrettably the slightly flexible construction of the PasPlugs sharpener is essential if it is to work and cope with wear of the grinding wheel. However it does well enough.

Although a robust, all metal direct copy is unlike to be satisfactory I see no reason why the reversible drill carrier could not be utilised in a device similar to the very expensive Kaindl BSG 20/2 shown in a brochure here :- **LINK** . This machine pivots the drill across the periphery of the grinding wheel via a horizontal shaft in a solid vertical post giving line contact and inherently accurate grind. The setting jig would, of necessity need to be a separate unit rather than integrated like the PlasPlugs version but that doesn't seem a great obstacle.

In principle I see no reason why a drill sharpener of that, vertical post, style couldn't be marketed for an affordable price maybe £40 or so with a simple guided slide base rather than the micrometer setting device on the Kaindl. Might well need two setting jigs and two carriers to cover the full 1/8" to 5/8" range claimed for the common swing across the wheel variety. I see no reason why an engineering plastic shouldn't be acceptable for the carrier and setting jig if metal proves too expensive.

Some pictures of the plasplugs device :-

In action grinding the first cutting edge with the carrier upright, note the setting jig on the left

Using the setting jig. The drill point is pushed up to a metal stop and twisted until the floating Vee block drops to its lowest point. In this picture the drill is at the wrong angle so the Vee block is too high allowing the stop to be seen.

Drill at correct angle with the Vee block at its lowest point seated on the tips of the cutting edges. Note the shape of recess for the drill carrier in the swinging plate which allows it to be simply inverted to do the second edge without needing the drill to be reset. A major major advantage over the common swing jigs.

Here is a front view of the drill in its carrier showing the 5 to 5 position of the cutting edges. Same as the Picador jig.

Finally a side view of the carrier and (seriously mankey) drill. Grabbed out of the scrap box for photo purposes hoping the slight rust would give better contrast.

Getting back to the original Draper device I have a set of instructions for the American General No 825 version which gives some guidance as to drill projection. PM me if you'd like a copy. Its about the best set I've seen for such jigs.

The overhang is measure from the lip rest at the front of the trough. Pictures are somewhat misleading as, unlike to Picador system the lip rest is rarely in contact with the drill flutes. Interestingly the grinder is shown working on the periphery of the wheel rather than the side as is normally specified.

Clive

Edited By Clive Foster on 26/06/2019 22:55:03

Edited By Clive Foster on 26/06/2019 22:59:05

26 June 2019 at 23:00 #416264Mark Rand

Participant@markrand96270Note:- a four facet (or any facet based scheme) has too much relief at the outside edge.

Commercially produced split point drills including Dormer and others, are usually a conventionally produced geometry with a flat secondary clearance added to it, not a four facet design. This reduces the axial force needed by making the web smaller (with the extra two cutting edges that are produced where the web was cut away), but retains the correct relief nearer the outside of the drill point that prevents the drill from hogging if pushed too hard.

Edited By Mark Rand on 26/06/2019 23:03:46

26 June 2019 at 23:58 #416276Clive Foster

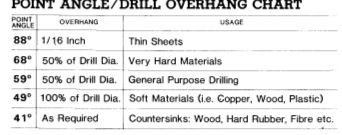

Participant@clivefoster55965Gah, table of projections for the General jig didn't upload in my previous post. 2nd try :-

Getting back to the original Draper device I have a set of instructions for the American General No 825 version which gives some guidance as to drill projection. PM me if you'd like a copy. Its about the best set I've seen for such jigs.

The overhang is measure from the lip rest at the front of the trough. Pictures are somewhat misleading as, unlike to Picador system the lip rest is rarely in contact with the drill flutes. Interestingly the grinder is shown working on the periphery of the wheel rather than the side as is normally specified.

Mark makes a good point about the inherent excess heel clearance of acted grinds. In practice its not an issue with technically guided drilling systems such as mills or pillar drills. These keep things straight enough until the drill is deep enough to register on the sides of the hole. Unless the drill is very blunt or grossly over fed.

Different matter for hand held systems where the drill will wander all over the shop given half a chance unless it has a seriously deep punch or other mark to start in. masonry drills are facet grinds and we all know how they tend to wander. Careful use of the speed control on a battery drill can work but absolutely zilch chance with a hand cranked drill. Hand cranking is probably why the cone point became dominant.

Clive

27 June 2019 at 03:11 #416283Hopper

Participant@hopperWith a bit of practice you should be able to use your sharpening jig to give the conventional conical shape, then by hand, using the corner of the 6" bench grinder fine wheel, grind extra clearance where the second facet goes on a factory four-facet bit. This comes up as a crescent shaped facet. You can also extend this freehand facet up to the point to narrow the point down to approximate the point of a four-facet or split point bit. Just takes a bit of practice. Probably not practical on drills much under 1/4" diameter but works well on the larger stuff, where it is most needed.

Also known as web thinnning, although the above takes it one step further. See link here for sketches and pics that might be clearer. LINK

27 June 2019 at 07:58 #416312CHARLES lipscombe

Participant@charleslipscombe16059Over time I have read many comments on the forum to do with drill sharpening, but have never seen it mentioned how the drill manufacturers manage to get a perfect result every time. Does anyone know this?

For my part I have a Picador grinding jig which I modified in accordance with Graham Meek's recommendations.It can't give split point or 4-facet sharpening but works very well for basic sharpening. At this stage I don't think I have an actual need for more sophisticated sharpening (as opposed to wanting) so I am quite happy with the situation.

Chas

27 June 2019 at 09:17 #416340Anonymous

Posted by andrew lyner on 26/06/2019 14:50:34:I notice that people make very adverse comments about overall quality of what most of us use as a matter of course.

If that was aimed at me then I'm afraid you're wasting your time. Water and ducks back spring to mind.

You may eventually learn that the price/performance curve is non-linear. Much excellent work is done using far eastern equipment. However, particularly for accessories and tooling there comes a point where cheap is simply a waste of money. I'd argue that the beginner should be using quality cutting tools, not necessarily the best, but good value for money. It's not uncommon on the forum to see posts about poor finish or inaccurate work. Many times this is simply sorted by changing to better quality. This applies to milling cutters, drills, inserts and material. Oddly I've seen a couple of adverse comments recenty about the quality of far eastern HSS. Not something I can comment on as I've not used any of it.

Andrew

27 June 2019 at 10:06 #416359Hopper

Participant@hopperPosted by CHARLES lipscombe on 27/06/2019 07:58:14:Over time I have read many comments on the forum to do with drill sharpening, but have never seen it mentioned how the drill manufacturers manage to get a perfect result every time. Does anyone know this?

They use some very specialized machines – see Youtube. But the principle is very simple and the same as used on drill sharpening attachments for commercial tool and cutter grinders. The drill bit is held offset at an angle and rotated so the end against the grinding wheel is moved in the desired conical shape. Back clearance on the resulting conical face is provided either by adjusting the exact location of the centre of the swing of the drill bit via the holding fixture, or by a an axial camming action on either the holding fixture or the grinding wheel itself. As an apprentice I spent long shifts sitting at the T&C grinder, mounting drill bits up into the fixture and sitting there cranking the handle to rotate the drill bit while bringing it up to kiss the grinding wheel. The rig looked a bit like a meat mincer with the handle you cranked. An absolute no-brain operation once the drill bit is mounted correctly in the holder.

Or they go the other way in mass production, like in the below video of a Cincinnati Spiropoint where bit stays still and the grinding wheel circles it in a cam-operated loop. These days they would do it all with CNC of course.

Edited By Hopper on 27/06/2019 10:35:55

27 June 2019 at 10:44 #416370andrew lyner

Participant@andrewlyner71257Posted by Andrew Johnston on 27/06/2019 09:17:46:Posted by andrew lyner on 26/06/2019 14:50:34:I notice that people make very adverse comments about overall quality of what most of us use as a matter of course.

If that was aimed at me then I'm afraid you're wasting your time. Water and ducks back spring to mind.

No; not particularly aimed at you and I agree that total rubbish is total rubbish. But a beginner, given the choice of a small item at £20 and the 'same' one for £2 (and needing a host of such things just to get started) cannot contemplate the initial high total cost of tooling up.

Perhaps a more measured response (this is a general comment and not aimed at you) with some actual suggestions of the less bad budget sources would be helpful.

Water and ducks backs applies to me too but forums (many different disciplines) can get very elitist if not careful and, when that happens, they lose potentially skilled newbies. I don't think anyone would be unaware that high quality kit gives better results but very few newbies start off with model steam engines and diesel injector valves as projects. Over the years, people will steadily use better stuff as required.

I realise that someone who started their life as an apprentice would have probably been trained on high grade equipment so using poor quality stuff is unthinkable for them. Many of us have to buy everything we ever use and start off at the 'garden gate latch' level of quality. Still a valid way in. I remember my life in Broadcast Engineering Research and we had only the best test equipment. If you bought an item of Hi Fi equipment for home, it had to cost an arm and a leg – just to maintain the standards that your employer worked to. Not always appropriate and it kept many of my colleagues poor, as a result.

Advice on where to pitch ones purchase on the "price performance curve" would always be more valuable than just being told to buy the best, which is actually unattainable for a beginner.

My basic point is that I believe this is essentially an amateur forum and that point can easily be missed by people with a professional background. There is a difference between the excellent and the adequate. Excellence is expensive to achieve in virtually every field of endeavour and achieving the adequate is not necessarily a failure. In fact, over-Engineering is not necessarily good Engineering.

That said, I find nearly all the advice and opinions on this forum very valuable. The work that people do is really impressive.

27 June 2019 at 10:55 #416373Andy Carruthers

Participant@andycarruthers33275@Andrew Lyner – you make an excellent point

I dipped my toe in the water with an inexpensive lathe to see if I would like the hobby, as a consequence, bought cheap and made some "bad" purchases initially, I like to think I am making better purchases now primarily from reading posts here

Back on topic – thanks to those posters imparting information – appreciated, I now have Dormer A002 on my wish list

27 June 2019 at 11:18 #416385 JasonBModerator@jasonb

JasonBModerator@jasonbOn the subject of drills I would say a beginner would be best off buying a reasonably priced set and then as they need replacing top up with better quality ones particularly in the commonly used sizes eg whole and half millimeter plus tapping sizes. The others that you may not use so much replace as budget allows.

When I started off individual drill bits were bought as and when needed from the local tool shop with pocket money or a twist of Dad's arm. That was back in the day when ME show was over the Christmas – New Year period so a set or two of unbranded drills followed as Xmas presents, probably still got 50% of the original bits some 35yrs on. Over the last few years as I have been spending a bit more time on this hobby the worn or rarely broken ones have mostly been replaced with the above mentioned Dormer (not Brittish made).

Even then I tend to wait until they are on offer from one of the suppliers or keep an eye out for boxes of the sizes I am likely to use most at the shows where they can be picked up at good prices and should have enough now to last me quite a while. I still don't always get Dormer as although I could quite easily go out and spend a few hundread on new boxed sets of all the sizes or even individuals I do think twice about the cost of there drills as the sizes go up so may got to another brand like Guhring.

Similar applies to Stub drills which I like as they save me cranking the head up on the mill all the time as well as being less flexible so they cut straighter and combined with the split point can in most cases be started without spotting/punching though I still do that for critical holes. As mentioned above I only have them in common sizes and the larger few in more economic brands.

I'm happy with my workshop which is mostly far eastern equipped and feel selective purchase of tooling makes a more cost effecting improvement than spending out lots on fancy machines and then scrimping on the item that actually does the cutting. Hardest thing for those entering the hobby is finding reasonable tooling at reasonable prices of which there is plenty from the far east but there is also a good amount of poor stuff that you may or may not get when buying at the very cheap end of the scale

29 June 2019 at 10:34 #416686Howard Lewis

Participant@howardlewis46836With regard to the comments about the clearance of four facet drills; a thought.

An End Mill with spiral flutes is effectively a four facet drill with a flat end, rather than the usual 118 degrees of a twist drill. And they work OK.

Twist drills ground with four facets cut extremely well, and with less effort than "round ended" ones, for the reason that Jason gave. The central chisel point has minimal are so the pressure generated by the axial force applied, is enormous, and the point cuts despite the minimal cutting speed.

D A G Brown made jigs, to allow drills to be four facet ground on a flat abrasive.

It ought to be possible to make up two jigs, in which the drill could be clamped at the appropriate clearance angle to be moved across the face of the wheel on a bench grinder to give a four facet effect.

Of course, using a cutter grinder is the ideal way.

Not having one, would the Eccentric Engineering sharpening device provide such a fcailty? Iwners/Users comments?

Howard

2 July 2019 at 22:26 #417123David Caunt

Participant@davidcaunt67674Andrew,

I spent ages with the Draper and eventually filed it in a drawer. The instructions were so poor. I ended up with chisels not drills

It was only after reading Harold Hall's excellent article on using the drill sharpener that the penny dropped.

Only 2 things mattered.

- Getting the drill projecting the correct distance from the axis of swing.

- Orientating the cutting surfaces so they meet the grinding wheel vertical. (This I believe means getting them parallel cone in effect)

With respect to the distance from the grinding surface I decided that it was a pain trying to measure. So instead I mounted the attachment on a surface with a scale attached and a line when the front of the trough touched the wheel see photo.

Harold had said the correct position for the drill was the one that gave the correct chisel angle (130deg). A larger angle was caused by the distance being too small and a smaller angle when the distance was too large. So I started with a 10mm drill and found 10mm was too close and gradually moved the attachment further out until the chisel angle was correct (against a pre-cut credit card ). Then carried out the same procedure with larger and smaller drills and plotted drill diameter against the distance to which the attachment should be set to give the required chisel angle. I now wouldn't be without it.

Edited By David Caunt on 02/07/2019 22:26:58

Edited By David Caunt on 02/07/2019 22:29:09

3 July 2019 at 07:29 #417134John Haine

Participant@johnhaine32865Posted by Howard Lewis on 29/06/2019 10:34:10:

……..

Of course, using a cutter grinder is the ideal way.

Not having one, would the Eccentric Engineering sharpening device provide such a fcailty? Iwners/Users comments?

Howard

It certainly would with an appropriate jig.

this is the end mill holder I made using an er16 collet chuck. Not obvious is that the top and bottom faces of the block are not parallel to give the two clearances. Might need to make an alternative block for the drill angles but it's straightforward. Max drill size would be 10mm. I might give it a go.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Workshop Tools and Tooling › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Taylor Hobson cutter grinder modificaton

1

2

Started by:

David George 1

in: Workshop Tools and Tooling

David George 1

in: Workshop Tools and Tooling

- 9

- 38

-

22 August 2025 at 22:29

David George 1

David George 1

-

Material advice

Started by:

tobyonekenobi in: Materials

- 8

- 17

-

22 August 2025 at 22:19

tobyonekenobi

-

QCTP for chester lathe

Started by:

Chris12 in: Beginners questions

- 9

- 21

-

22 August 2025 at 22:06

dk0

-

Museum donation

Started by:

Stephen Wessel 1 in: Introduce Yourself – New members start here!

- 2

- 2

-

22 August 2025 at 20:36

Bazyle

Bazyle

-

Blackgates 3 Way Toolpost Casting

Started by:

John McCulla in: Materials

- 8

- 9

-

22 August 2025 at 20:12

Clive Foster

-

This weeks oddity!

Started by:

Martin King 2 in: Help and Assistance! (Offered or Wanted)

- 2

- 2

-

22 August 2025 at 19:12

bernard towers

-

Casting – off center hole correction

Started by:

colin hamilton in: Workshop Techniques

- 9

- 10

-

22 August 2025 at 17:38

colin hamilton

-

A4 stainless

Started by:

David Ambrose in: Materials

- 8

- 10

-

22 August 2025 at 17:37

Vic

Vic

-

Granville lathe leadscrew change wheel

Started by:

JACK SIDEBOTHAM in: Help and Assistance! (Offered or Wanted)

- 10

- 17

-

22 August 2025 at 17:07

Howard Lewis

-

wood working

Started by:

Danni Burns in: Beginners questions

- 9

- 12

-

22 August 2025 at 15:55

Danni Burns

-

3″ Castings – Help/Advice needed

Started by:

Andy Porter 1 in: Traction engines

- 4

- 6

-

22 August 2025 at 13:15

JasonB

JasonB

-

AI ads

Started by:

Ian Parkin in: The Tea Room

- 5

- 5

-

22 August 2025 at 13:00

jimmy b

jimmy b

-

1″ Minnie Traction Engine

Started by:

milburyring@btinternet.com in: Traction engines

- 3

- 8

-

22 August 2025 at 08:53

milburyring@btinternet.com

-

Solar panel

Started by:

duncan webster 1 in: Electronics in the Workshop

- 8

- 13

-

22 August 2025 at 07:19

Michael Gilligan

Michael Gilligan

-

The stand alone weight for tower clock

1

2

Started by:

dk0 in: Clocks and Scientific Instruments

- 12

- 36

-

21 August 2025 at 23:59

Clive Steer

-

Install & commission of a Chester Cub 630 (Warco GH750)

1

2

3

Started by:

Calum in: Manual machine tools

- 22

- 74

-

21 August 2025 at 21:52

noel shelley

-

Asong power feed?

Started by:

Hollowpoint in: General Questions

- 4

- 4

-

21 August 2025 at 21:43

andy198712

-

Softening epoxy

Started by:

John Haine in: General Questions

- 17

- 25

-

21 August 2025 at 18:57

Martin Dilly 2

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 35

- 226

-

21 August 2025 at 17:38

Dalboy

-

Denford Orac refit

Started by:

Richard Evans 2 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 3

- 4

-

21 August 2025 at 14:56

Richard Evans 2

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 10

- 12

-

21 August 2025 at 12:48

Clive Steer

-

F360 stock from solid

Started by:

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 9

- 16

-

21 August 2025 at 10:44

Roderick Jenkins

Roderick Jenkins

-

Harold Hall – 1933 -2024

Started by:

Neil Wyatt

in: Website Announcements

Neil Wyatt

in: Website Announcements

- 14

- 19

-

21 August 2025 at 00:07

Michael Gilligan

Michael Gilligan

-

Manual for Warco GH750 or Chester Cub 630

Started by:

Gavlar in: General Questions

- 7

- 16

-

20 August 2025 at 22:54

peagreenpete

-

Greatest Model Engineer

Started by:

Juddy in: The Tea Room

- 17

- 24

-

20 August 2025 at 21:41

Nigel Graham 2

-

Taylor Hobson cutter grinder modificaton

1

2

-