Hopper,

I have run the first test you suggested.

I ran the carriage down to the tailstock end, snugged up the gib screws and then brought it back towards the headstock. The movement of the carriage became progressively easier (read looser) towards the middle of the bed way until, very close to the headstock, it became even tighter than at the tailstock end, very difficult to move.

Testing with a bit of shim stock between gib and dovetail proved inconclusive due to limitations, both in my ability as well as the variety shim material thicknesses available to me.

The second test you suggest – measuring across bar material in the dovetail groove will not serve me well here.

The design of the bed of the ML 7, having flat ways with squared off sides means that the wear of the bed on the top is not linked to wear of the sides and/or gib.

On the other hand, on the ML 10 the dovetail design of the bed way means that wear either in the dovetail against which the carriage and gib bear or on the top of the bed itself will both have an effect on the back and forth carriage movement.

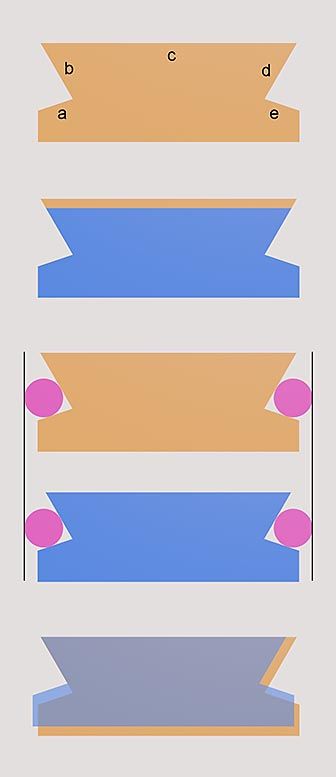

You can see this from my little illustration below.

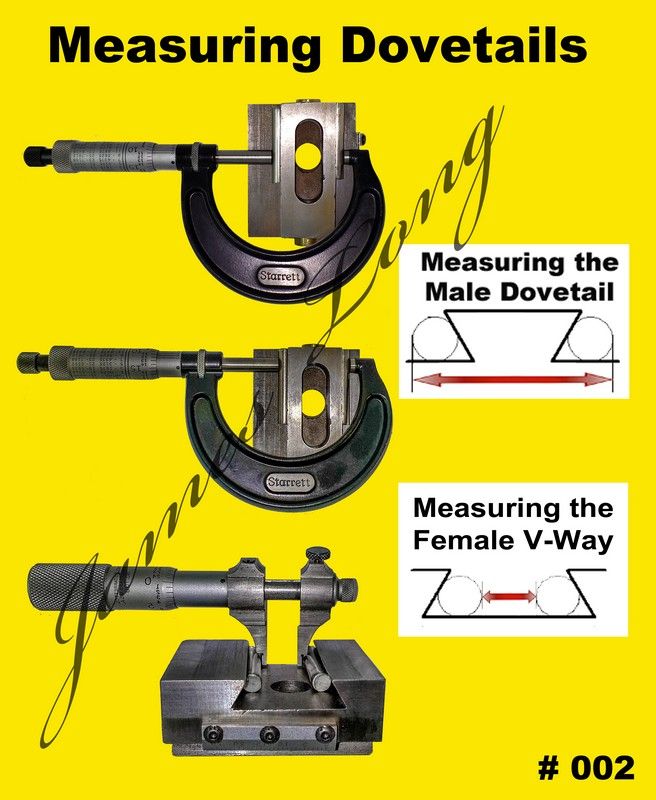

The dovetail test in the image you attached to your last post indicated a reading across test bars placed down in the grooves formed between dovetail and bed.

That would be thus mean reading across bars riding in the grooves a/b and d/e

Unfortunately, the carriage does not really bear on those grooves, instead referencing itself to the corners formed by b/c and c/d

If we wear away the top of the bed way (exaggerated here for clarity) the measurement across the rods in the grooves previously indicated will still remain the same (for all intents and purposes), but the actual cross-section of the bed as experienced by the carriage will have been reduced. This is presented by the lowest image where I have superimposed the worn cross-section of the bed way over the original.

Ignatz.