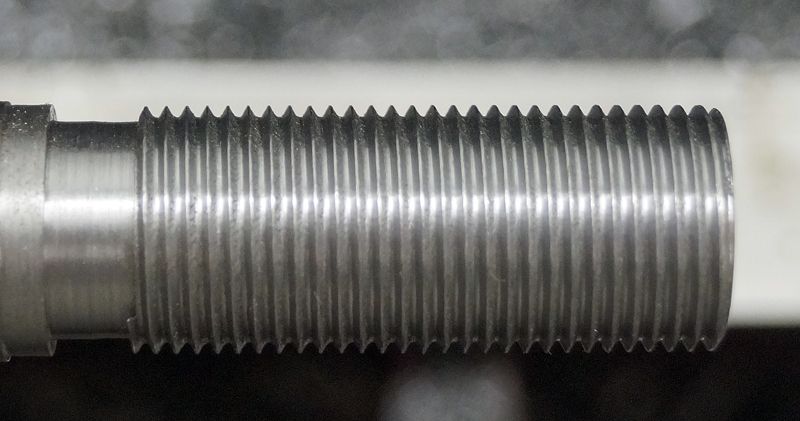

I have another issue with the lathe, I am now struggling to produce a good surface finish with it. I never had a problem with it previously, I could always get a an excellent finish so something has changed and I am wondering what..?

This morning I spent some time re-adjusting the gibs, setting them up as good as I possibly could and there is no play in both the top and cross slides. There is no issue with the carriage either so all seems to be good from the bed up to the tool post.

I re-sharpened and tried two HSS tools and also a brand new carbide insert but there was no improvement. The finish is not horrendous but its not as good as it should be or as good as the lathe gave before.

Unless you guys can think of any other cause I am wondering if the head spindle bearings are on their way out. The lathe is less than a year old so that shouldnt be the case but if I am unlucky and they are dodgy bearings..? Having said that I cant feel any play or end float in the spindle but if they are starting to become an issue I can imagine them first showing up in the cut finish.

For £20 I can get a pair of angular contact type bearings as replacements, they are said to be an improvement over the originals anyway. I cant think of anywhere else to look for the problem.

Oldiron.