Posted by Ron Laden on 27/01/2019 10:16:51:

…

Would I be right in thinking that the uncut sides and ends could be difficult to machine, just thinking of the best approach as it will be the first time with cast iron.

Maybe, maybe not. My experience of cast-iron is that it's machinability varies between very good (but dirty) and impossible. There are three potential problems:

- Ad-hoc cast-iron as used to make weights and drain covers is often full of impurities. All that matters to the foundry is that it pours into the mould and makes a casting that looks OK. Inclusions, blow-holes and other faults are likely. Pot-luck as to whether this variety of cast-iron machines or not.

- Cast-iron is also made to a specification as a proper engineering material. There are perhaps 30 or 40 different alloys available for different purposes, and not all machine well. However engineering cast-irons are much less likely to cause workshop problems than cheap castings.

- Cast-iron is prone to develop a hard-skin caused when the outside of a casting (including bar-stock) is cooled quickly. Sometimes cast-iron is chilled deliberately, more often it happens accidentally.

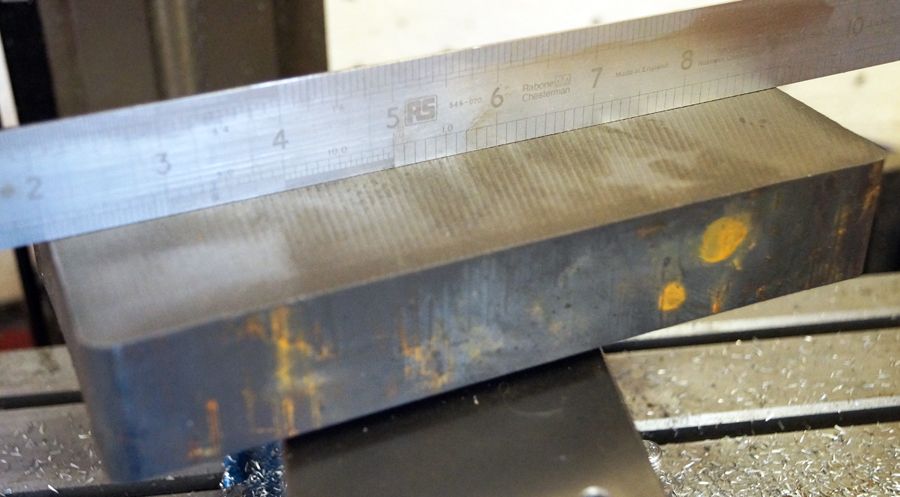

I expect your bought cast-iron will be 'good stuff' inside, but it might have a very hard outer skin. The hard outer skin can damage HSS but carbide will cut it. Once through the skin, cast-iron is usually easy to machine. (Unless it's an old sash-weight!)

My main source of cast-iron is a block from an old hot-air heating system. The metal inside is good but the block has an extremely hard skin perhaps 3 or 4 mm deep – it takes the teeth off a hacksaw. I cut the block with an angle grinder and scarify the skin with it. Once the skin is off, it cuts delightfully.

Finally, I advise taking extreme measures to contain the mess! Cast-iron is a mixture of carbon, iron, and carbides. Cutting cast-iron releases a lot of finely powdered graphite, it's black as hades, goes everywhere, and sticks. The carbide particles make a first-class grinding paste – you don't want them on your lathes sliding parts. Cover everything up and try and contain the shavings close to the chuck.

Dave

Ron Laden.