Too true!

The rule of thumb is that if you have a spare cutter you won't break the first one. If you don't you will. The smaller the cutter the firmer the rule.

I've recently made some bevel gears using a 1mm ballnose cutter. In all 20 hours of machining with the same cutter; but of course I had a spare.

Andrew

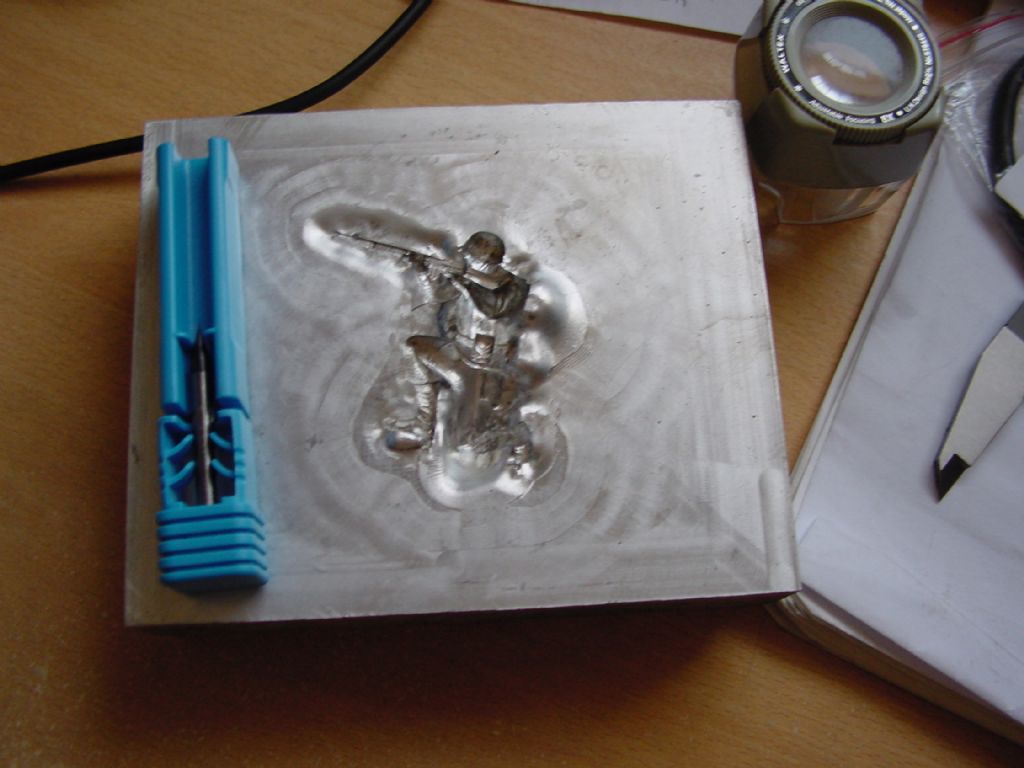

I made a test piece a few years back for an injection mould tool here's a pic of one half, its quite dirty now and is only used as a paper weight but you get the idea, the finishing path was also around the 20 hrs mark, 0.3mm ball nose cutter these aint cheap!!, the figure is approx 52mm kneeling down, with an eye loop you can see the knots in his boot lases, I remember the split line was a nightmare to draw, bit it did shut off ok with no flash, I later went on to machine 20 odd of these in differing poses and uniforms………..

Pen top to show depth

Involute Curve.