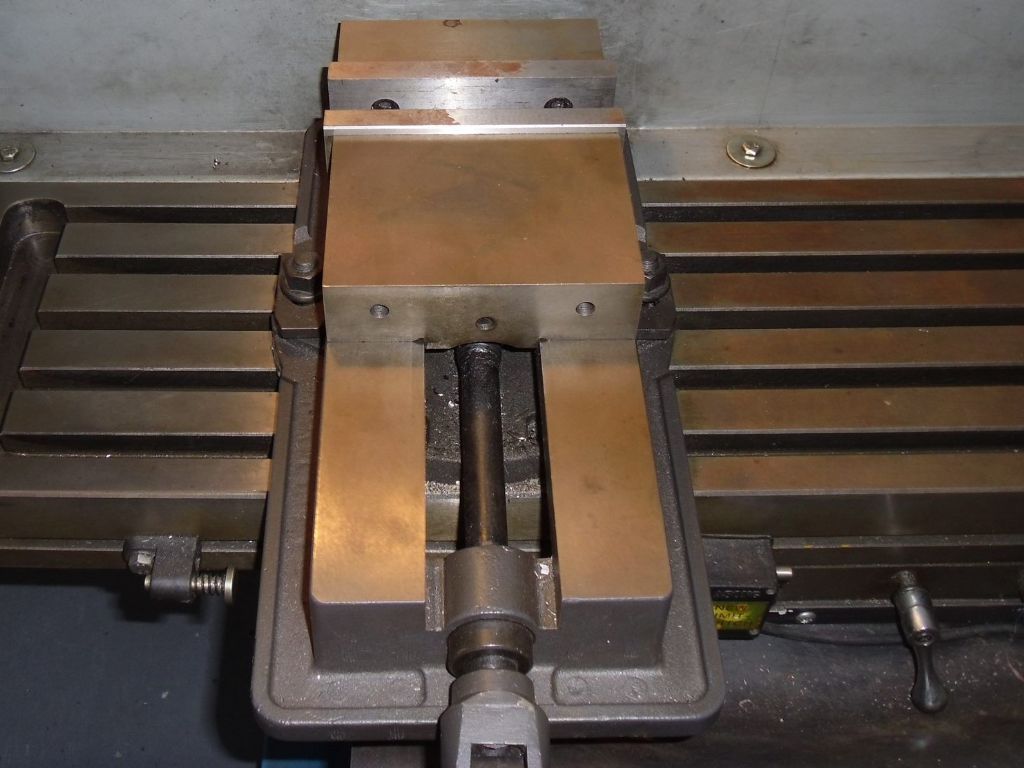

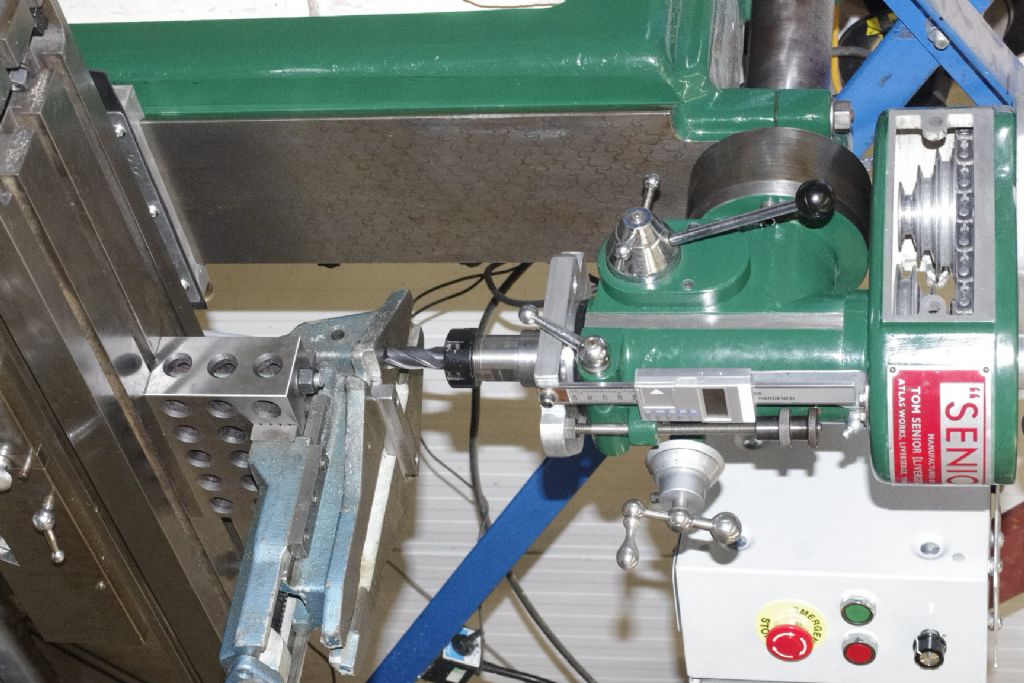

I have a milling machine with a Free vice that was part of a package deal some 12 years ago. The owner said it needed these shims to try and square up the vice and he did not use it much due to it not being accurate. I have stripped it down over the weekend. It has no name brand on it to be seen. It looks like a Vertex vice but is not the quality of the only vertex vice I have seen.

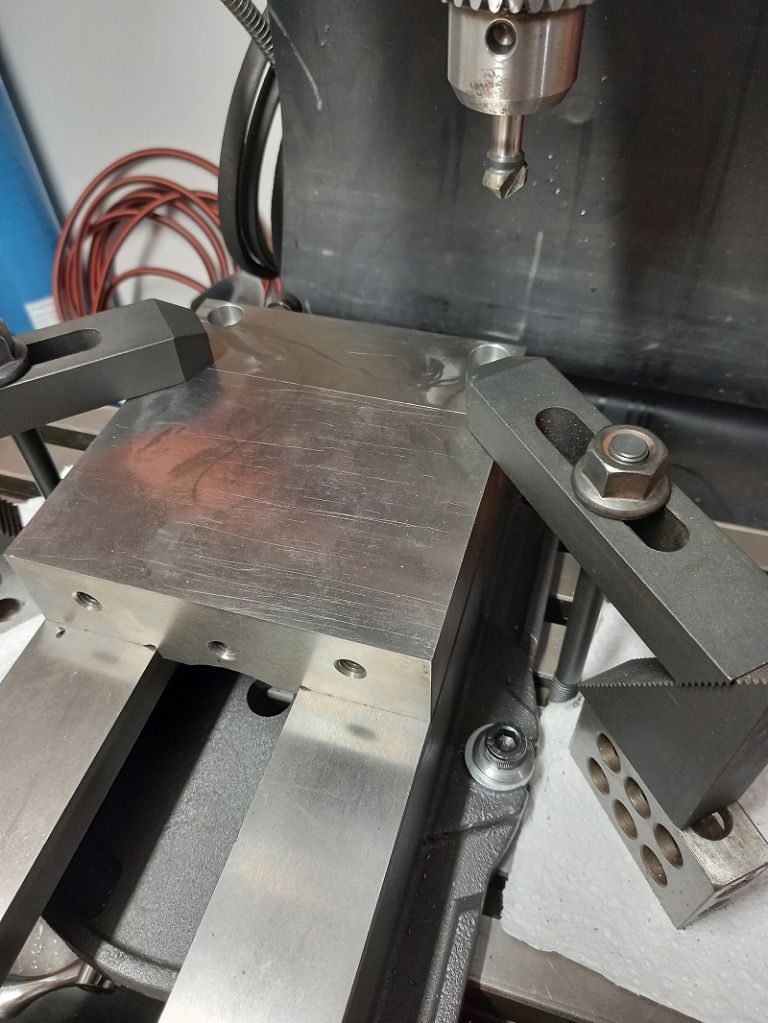

The base is not flat nor is it parallel , with a micrometer has an error of up to 0.2mm .

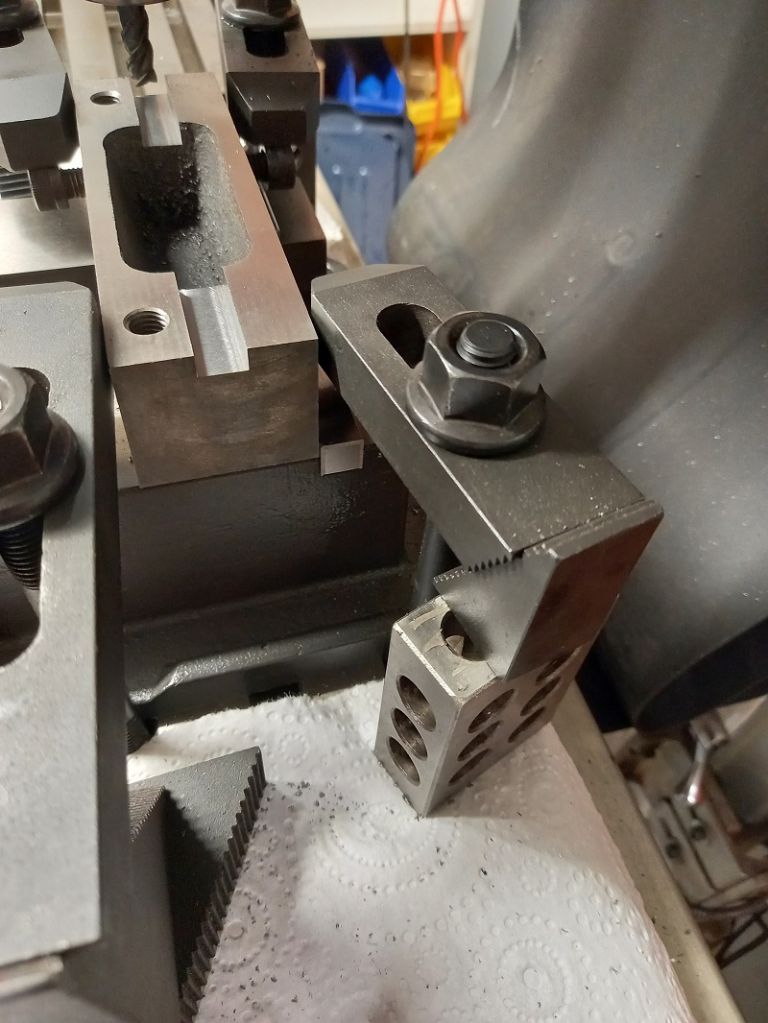

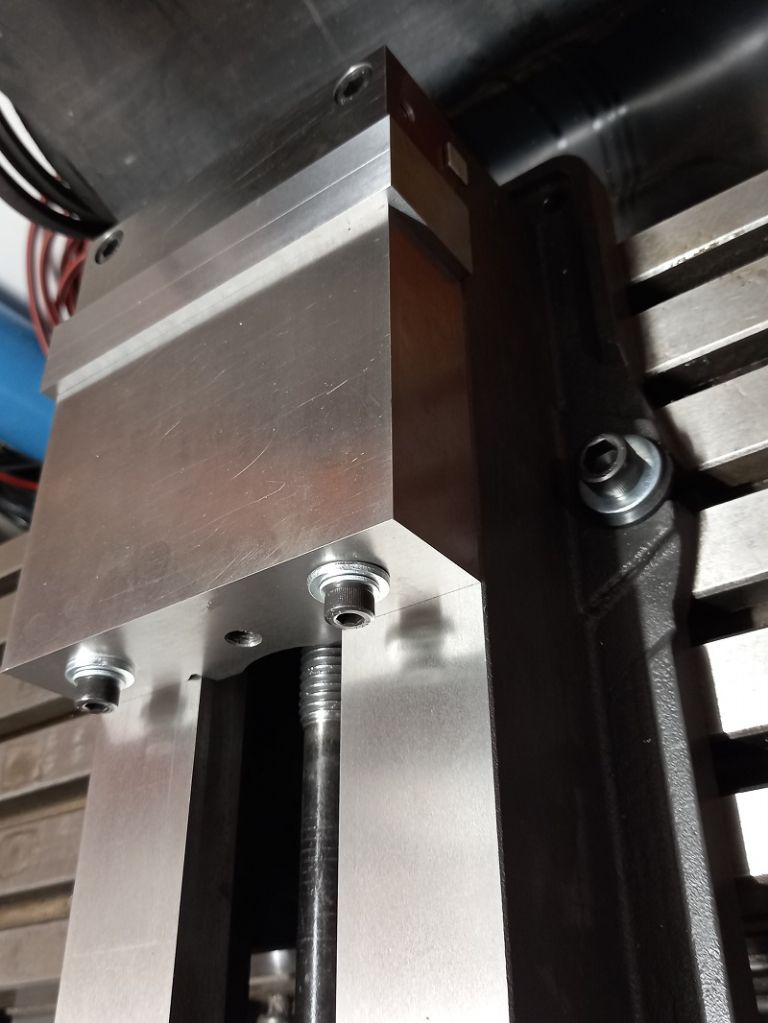

The fixed jaw block is not parallel or square to the keyway slot. It is a good fit to the keyway though and the key fit to the base is good. They got that part right. The fixed block error is around 0.15mm out of parallel from the bottom to the top. And then over the length has a similar error of 0.18mm.

The moving jawblock has similar errors to the Fixed jaw block but over a loner distance.

When the vice was all assembled, it all looked very nice, with hardened jaw insert that all aligned up about even for height and width when closed, but did have a funny looking gap at the bottom.

I have done No investigation to the swivel base that has come with the vice.

My question is, what is the normally acceptable run out on a milling vice for hobby use? This is a large vice with the Jaw width being 6 inches and has a swivel base as well. I found a picture of the vice.

Neil

Neil Lickfold.